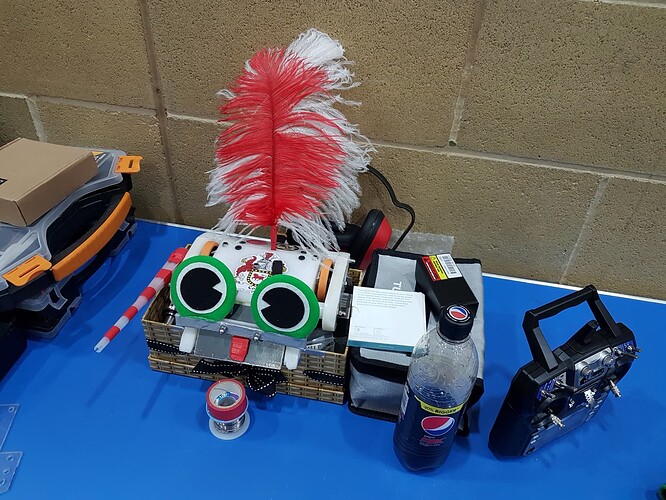

Sir Lance-a-frog v1

aka “Baby’s first robot”

The original frog was a very safe and simple design, based on the ‘standard’ components of the time (1.0Ah 3s lipo, 25mm motors for drive, 3/8” Banebots and a thicc servo), not doing anything flash or tricksy, because my tools then (and still now) were very bog-standard stuff. The lifter was a simple 3mm mild steel plate hinged at the top and lifted by the chonkmeister of a servo I found off HobbyKing. Somehow totally non standard which made finding replacement servo horns impossible, but just worked. ESCs were BB10s, again just for their simplicity and tendency to just do the thing asked of them with no questions asked.

All versions of Frog have followed the same basic principles: 15mm HDPE for the chassis walls, 5mm for the top and baseplates, and then a mixture of thicknesses for the other parts. Wheelguards have varied between 5, 10 and 15mm versions, Front wedges and wedgelets have always been 5mm, and all have used M5 nuts/bolts/fixing because it felt like the most robust solution for the size and thickness of HDPE. When it came to actually constructing the bot, all parts followed the same guide: print the design 1:1 scale onto paper and then stick it to the slabs of HDPE, before cutting them out in a very efficient manner.

[Yes, that is many many holes drilled around the perimeter of the chassis walls. Yes, I had to sand everything down afterwards. Yes, this is how the first frog was made. Yes, I know this is a challenging image to process]

I’ve used a multi-tool since then to cut out the bulk of parts. I learnt!

Another aspect to being a simple design, was it allowed focus on making it a solid design overall. I always tend to favour robustness over all: Build your robot to take a hit, be able to react to that hit and take more if needed. By tanking a hit and being able to keep going, you give yourself time and opportunities to get a lucky counter, or just to wear your opponent down. This design choice lent itself well to making it out of thicc bits of HDPE, which would be fair easier to manage, to repair or to maintain at an event, than mild steel or other materials.

[CHASSIS ONLY]

As far as competing? It did reasonably well at UWE 2018, managing to win it’s first two fights, my first fights in robot combat, before losing the next two. The latter fights are where I learnt my passive skill, my innate ability to find open pits and drive down them. Something something good habits forming.

The next event at Robots Live! Burgess Hill was a proper smack in the face, as Frog proceeded to lose it’s first three fights in varying manners, including another pit excursion, before picking up a solitary win.

By this time I’d already noticed a few things that I wanted to improve on v1:

- making the front of the robot a shallower angle, to help get underneath opponents

- changing the lifter from 3mm mild steel, to 2mm gr5 titanium for weight-savings and hardiness. Mild steel bent far too easily on spinner hits, which would leave large, awkward curls and cuts.

- Increasing the amount of internal space, as with large, bulky components there was barely any room for the delicious electric spaget that makes every robot do their thing.

[He silly. Fun Fact #2, I stopped putting feathers on the robot when they got sucked into the drum of Swag Demon during a rumble. Imagine if the FRA had heard about this!]

It quickly became apparent that making these changes to v1 would prove very difficult – so the decision was made to create v2, and v1 would hop onto the shelf to enjoy retirement, with a record of 3 wins, 5 losses over 11 fights at 2 events. Not the worst start.

In summary: Got my foot in the door and left me wanting to do more.