This post explains how I adapted a motor to a different gearbox not designed to work with it, it’s intended as inspiration to others who might want to do something similar, not at any specific weight class, but this is for my Featherweight.

For my lifter weapon, I was using 2x 36mm “RS540” motors from Aliexpress, with matched 36mm gearboxes at ratio 51:1 also from Aliexpress. Those have 8mm H shaft output which drives a metal hub thingy and 3d printed final reduction gear to drive the lifter.

Although that worked quite well, I found the gearboxes prone to failure due to the extremely high torque required to lift a potentially 13kg opponent.

So I’ve adapted it to use a 42mm gearbox and the same size of motor (a 775 motor would not fit in the chassis). I also changed to use a higher gear ratio (71:1) and more powerful 540 motor (55 turns instead of 80T) which will draw even more current but hopefully not cook itself.

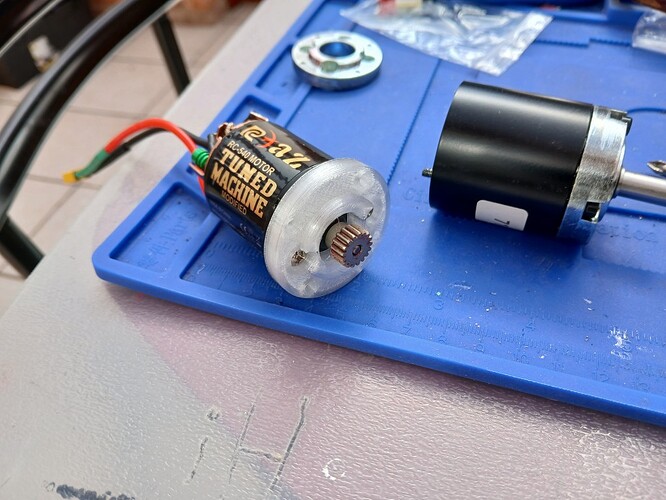

The result looks a bit like this:

So how did I do it?

The first problem is, that the 42mm gearbox comes with a pinion gear which is matched to the 5mm shaft of the 775 motors. This is too big and therefore won’t fit the 36mm motor.

So I carefully measured and counted the teeth of the pinion gear, and discovered that it was mod 0.6 and 17 teeth. Assuming standard parameters, only the modulus and number of teeth is required to be compatible.

I verified this by carefully taking pictures of the gear with my mobile phone, then measuring the picture on the computer and counting the teeth. Then I printed out on a sheet of plain paper, the gear with the parameters and checked that it seemed to match. I did this using Inkscape’s gear generator plugin but you could use anything which can generate gear profiles, as it’s only to check the modulus is really the same.

Then I set about browsing Aliexpress for a compatible gear. The result was from a listing called " 0.6M 3.175mm 7075 Aluminum Alloy Motor Gear 13T 14T 17T 19T 20T 22T 26T 28T 30T 33T Metal Pinion 1/10 RC Car Parts".

Finding this kind of thing on Aliexpress can be challenging, I discovered that the “M0.6” or “0.6M” are the magic keywords, there are otherwise too many gears.

These pinion gears have a small grub screw to mount on the shaft which is nice and seems to work (the 36mm motor has a flat on its shaft but the other pinion gears are usually press-fit)

After the parts arrived, I verified they matched (and they do).

The next problem is that the mounting plate for the 42mm gearbox does not match the bolt pattern of the 36mm motor. As this is only a moderately structural part, not part of the drive train, I modelled a replacement in CAD and 3d printed it out. A few iterations later I had one which fits really well.

The long M3 bolts which hold the gearbox together will screw directly into PETG plastic with no threaded inserts, etc, this works well enough. I modelled a chamfer on the holes to make them screw in more easily.

So far it seems to work ok, I’ll need to get it in the robot. The only other minor detail is that I now need to make the 8mm D shaft into a H shaft, but that should be a fairly straightforward dremelling job.