BBB new bloods is coming up and I couldn’t pass up the chance to do beetles at a local brewery - so I had to come up with a new beetle to secure my slot!

But what to make!? - I often find the blank canvas moment the hardest part.

I knew I wanted to make a “Spinner but…” - a bot that incorporates a spinner but has something a bit different or unique going on too. And ever since making my ant drum GetGot I’ve been wanting to try the oversized cambered wheels at beetle scale.

With this in mind I did what I often do and started with a rubbish sketch, and after a few nonstarters I ended up with this:

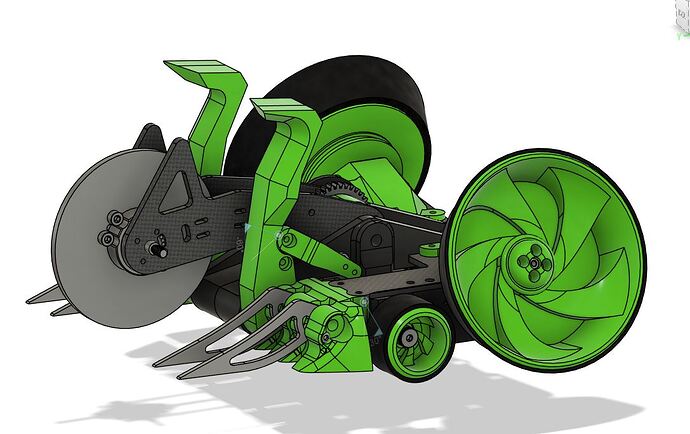

Big oversized cambered wheels and a puncher drisk seemed to tick all my boxes.

So off I went to cad and after many a wasted evening and early morning prework cad session - I had about 6 puncher weapon designs that I absolutely hated. So a rethink was in order.

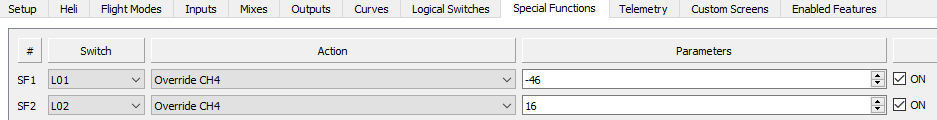

Annoyed at the puncher designs I started to think about how to achieve the goal of a retractable weapon more easily and the obvious answer is a hammer saw. Keeping the rotational movement as rotational movement is much easier than trying to convert it into linear movement after all!

But a regular hammersaw? - that didn’t feel anywhere near weird enough to satisfy my strange tastes. At this point I remembered Seth’s shrapnel mine, the original version that was a front hinge with a saw weapon, not the new tantrum esque puncher.

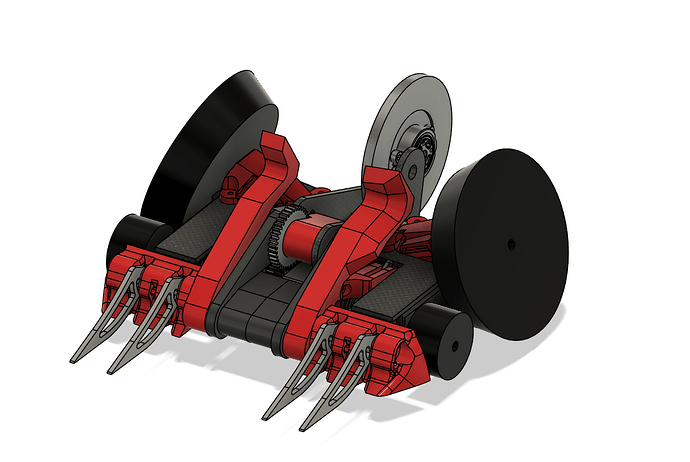

The idea of a bottom attack robot appealed to my need for gimmicks and if Seth isn’t pursuing it maybe I should? So I looked at his mech and quite quickly decided that separating the front hinge and the hammer saw would be drastically more useful in the arena and the new design started to form and relatively quickly I ended up with this:

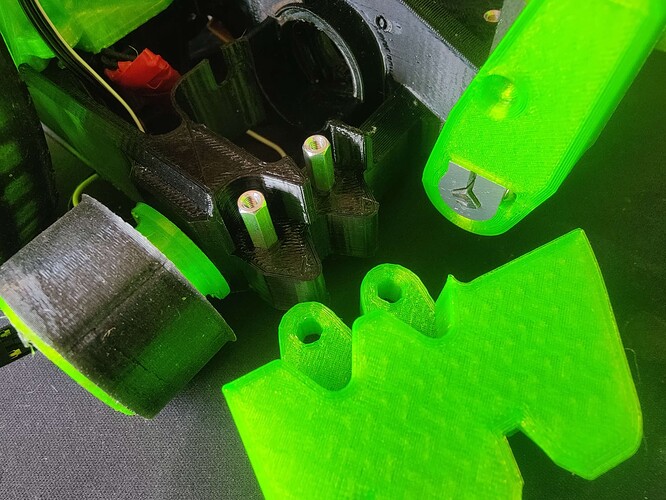

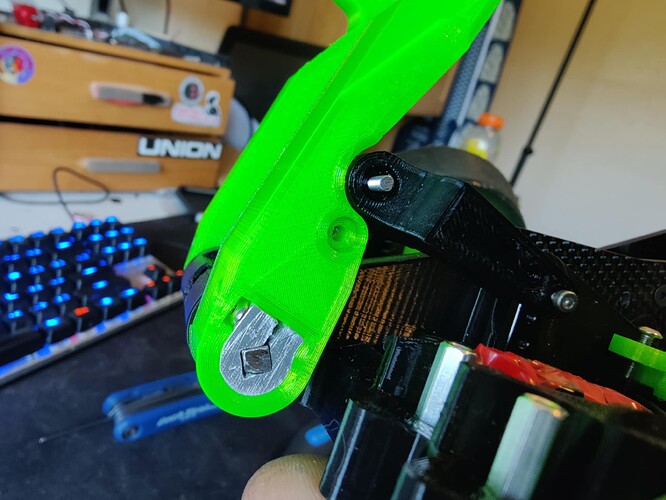

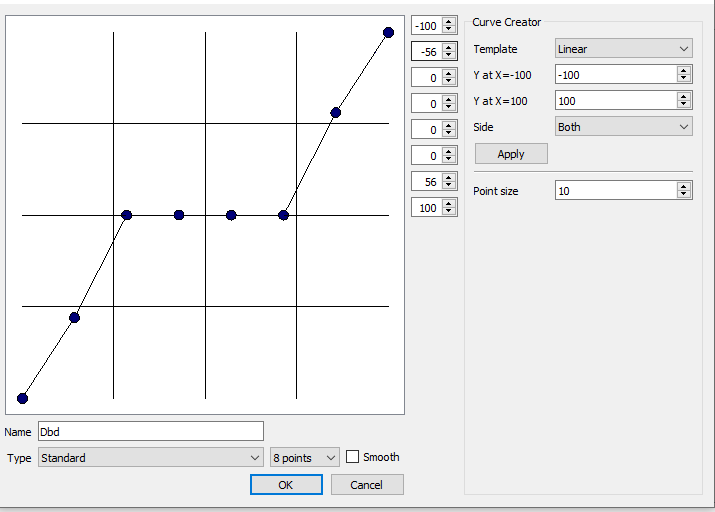

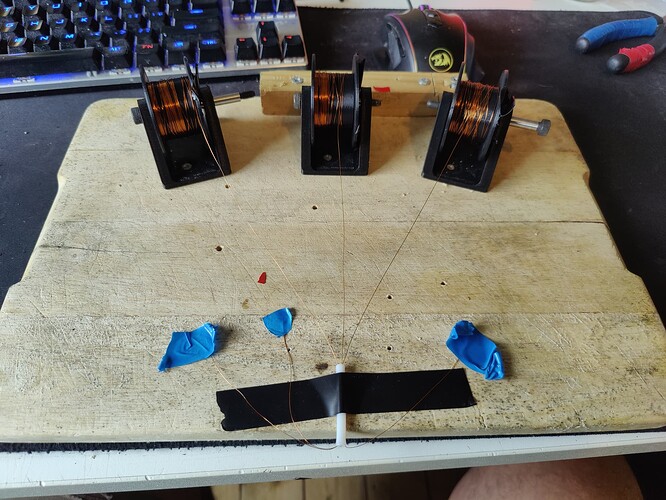

A lot of the early design decisions sorta made themselves. I knew I wanted to design around a repeat hub motor, this build was gonna be complicated enough without adding a custom hub motor to the mix. Weight was gonna be tight so carbon fibre and lightweight TPU prints where gonna the order of the day. And it was gonna have to be small and as dense as I could make it to get in weight. Round belts seemed like the simplest option for the drive, I felt a bit unsure of how the tpu construction would effect belt length and the round profile felt like the most accepting of the 20 degrees of twist involved in the camber.

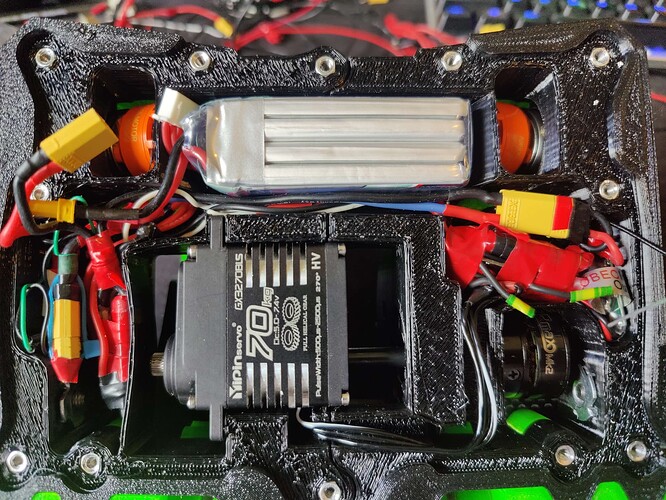

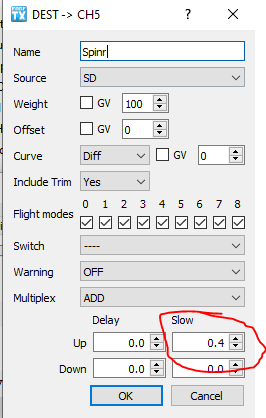

The hammer saw is powered by a repeat gearmotor with an external reduction stage and the lifter by a simple servo and linkage set up.

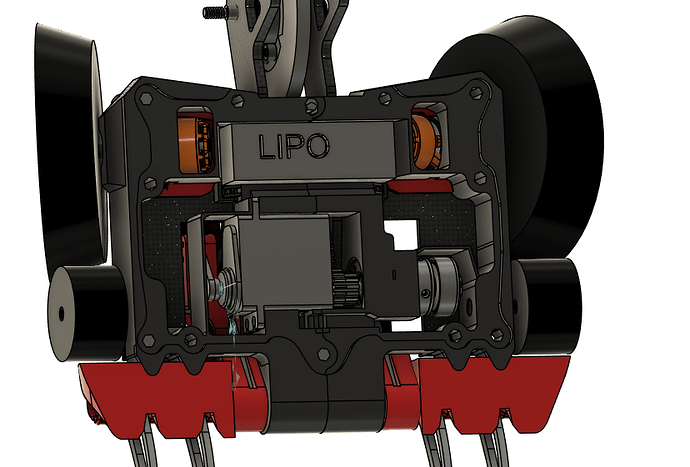

The layout was largely dictated by how I could most densely pack in all the component. I usually start designs by laying out the lipo, motors and servos and then building the rest around that layout.

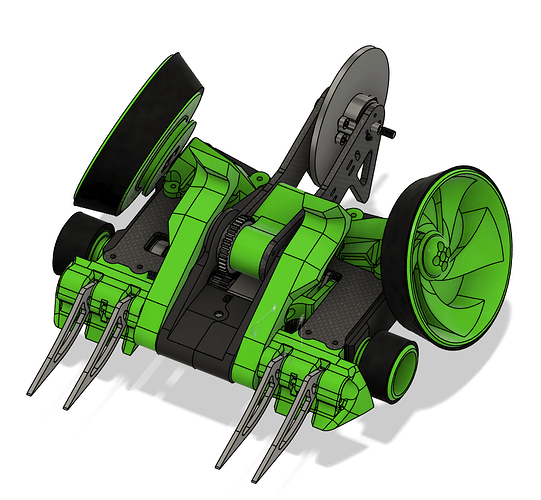

After a bit more tweaking I ended up with this

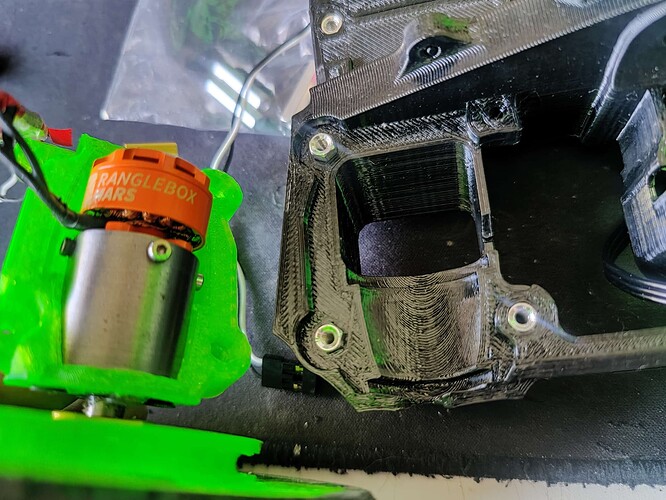

The chassis is designed in two parts, and is smoll, here’s one half:

I knew with everything being as light as I could make it, and with it all largely being tpu - I was gonna have to use some fancy geometry and lots of keying to ensure reasonable strength.

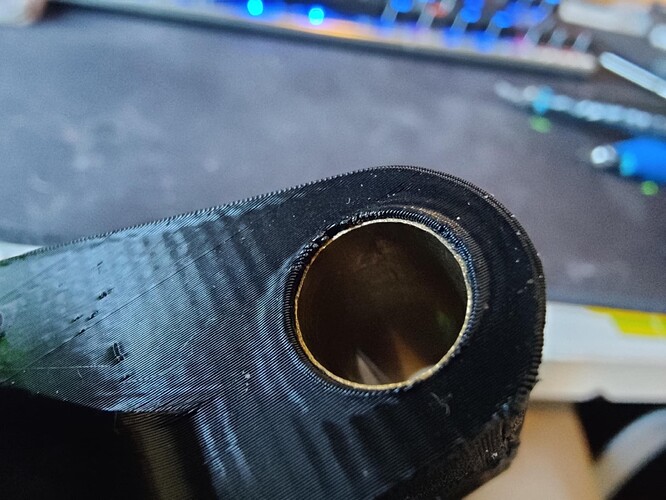

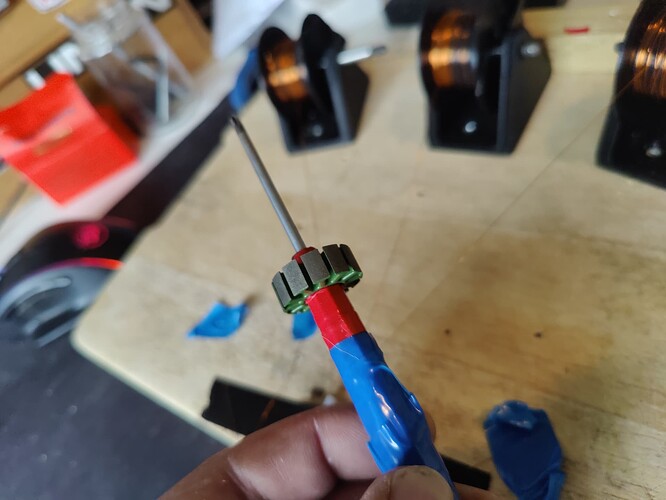

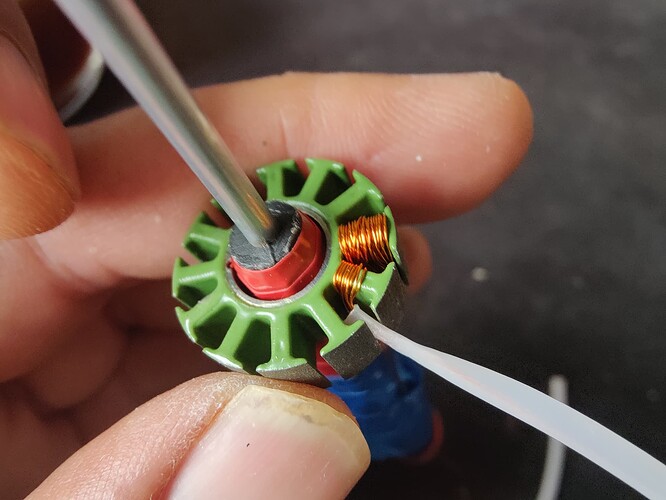

One of the trickiest parts was making the big cambered wheels. After a bit of trial and error I settled on using a multipart mold. A main mold cylinder and then a tapered insert for the camber.

Foamies would have been lighter but foamies are gross - I’m relatively happy with how light I got them despite the size

I’m still tweaking things, but the bot is together and drives

Wiring it up was a bit of a 'mare. With four brushless motors, four separate escs and a servo, with all the electrics crammed into two very small spaces on opposite sides of the bot, it was a bit tricky, but we got there.