‘Done Enough’

LIFT!

I’m calling it here for CAD updates. Not much significant is likely to change after this, so aside from following up on replies and suggestions to this update, expect this thread to go dormant until I have some build news. But basically, it’s done!

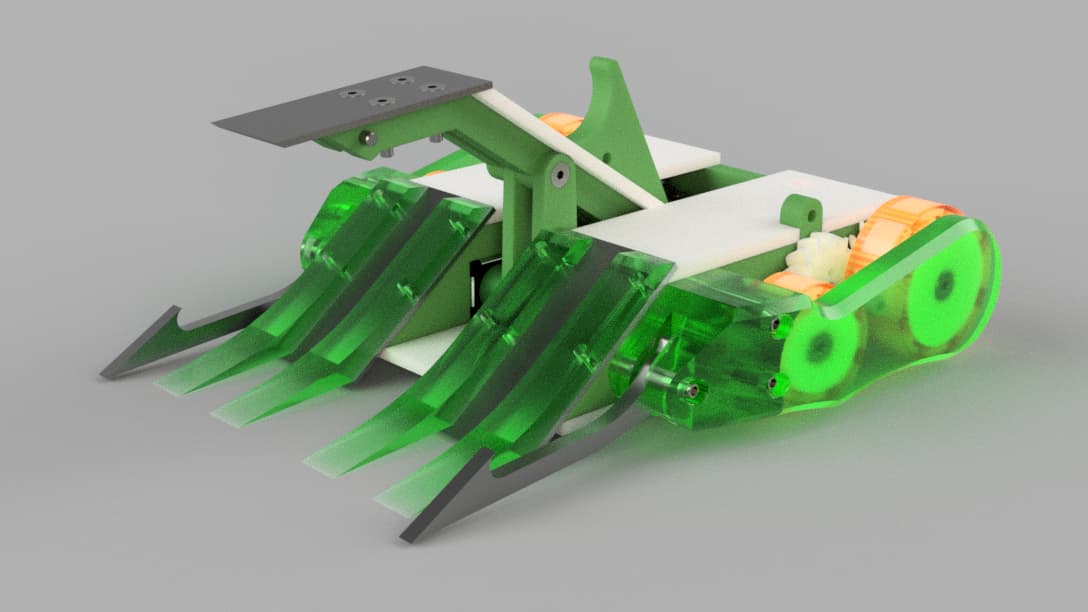

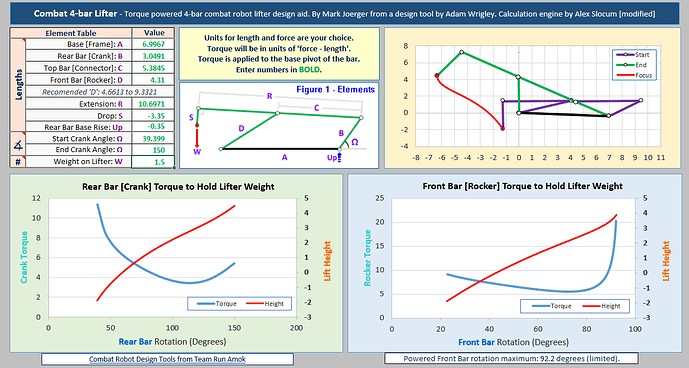

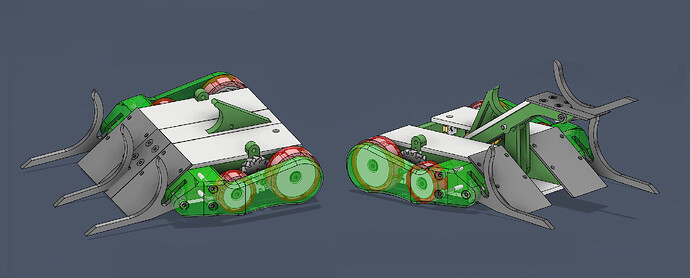

The first point to follow up on is, as you can see, I learned how to create a moving linkage. It’s called a Contact Set, and is created by putting revolute joints between each part of the linkage, then selecting all the bodies for the set. It basically simulates collision between the bodies. This has been incredibly helpful, allowing me to view a weapon design in three dimensions for the first time. I didn’t need to adjust my forks at all, but I did lengthen the rear bar to increase both the upwards and forward throw of the weapon, with minimal impact to the required input torque. It now raises by 89mm and extends 43mm.

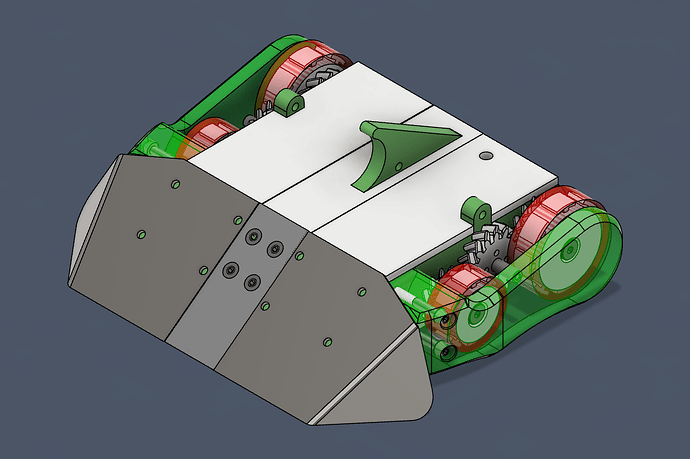

Next up, I finished tweaking the setups, learning the sheet metal workspace to design a 2mm Bent Titanium wedge. After I made the setup for Crossblow II, the robot never lost a head-to-head fight with a horizontal spinner, so I’m confident that this will continue to perform well.

Always the sexiest setup. Could still run with the TPU forks in case of forky horizontals

The drum setup followed, and I improved the mounting on the middle fork. It flops a little, but rises with the lifter when fired, simply because that was the best place to mount it. We shall see how well that works. Since the lifting panel will be the fork’s endstop, I’ve decided to put in M4 bolts with nylocks, rather than 4mm woodscrews, to prevent the fixings from backing out. Unfortunately, there isn’t really space or material to use M4s or barrel nuts for the main wedge plates, so screws will have to suffice.

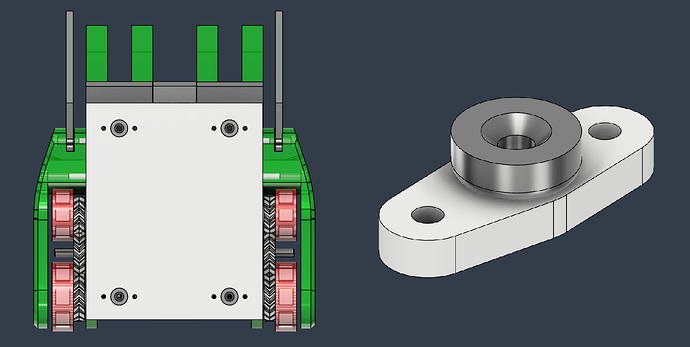

The last major change is the addition of magnets. I’ve never played with them before, so please critique what I’ve done! I selected some 12mmx4.5mm N42 Neodymium Pot Magnets, and have mounted them through the baseplate into a UHMW mount. There’s a 4.5mm gap to the floor, and a pull-force of 235 grams each. There’s one in each corner, both to pull the TPU forks flat, and to provide traction to the rear wheels when there’s weight on the lifter.

There were numerous small final jobs to wrap up the project. I’ve put a switch into the design for now, as they seem so easy to design around. I’m aiming for a Rapture completion date, which has yet to announce it’s stance on switches, so this may be altered nearer the time, and I’m currently assessing the fuse options. The weight calculation sits at 1260g (I forgot to add in the Mars motors, duh) which may not be enough for a minibot, but is certainly enough for the woodscrews, cables and other odds and ends not currently factored in. 2mm Hardox sourcing may, in fact, be possible, so watch this space, and I’m hoping to get the first parts - the forks and titanium - sent off with Jed’s metal order at the end of the week.

I think that’s everything I have to share for now. Thank you to everyone for your advice and kind words so far. An especially big shout out to Morgan, and my constant CAD critics Sion and Rob for steering me right. I plan to take my time in the build phase while I juggle adulthood, but rest assured that this thread is not over. As for CAD, I’ll be moving on to do some final bits for the (semi-retired) Barber Surg3on, before starting work on designing a brand new, hubmotor-equipped iteration.

Until then, Goodknight!