One small thing - I wouldn’t personally put magnets ahead of the front driving wheels, in case you get bogged down on them when something goes up your wedge. Otherwise, very fun, very cool, looking forward to seeing it in an arena.

The Progression on your design from your first build is mind blowing!

Keep the updates coming.

The Build:

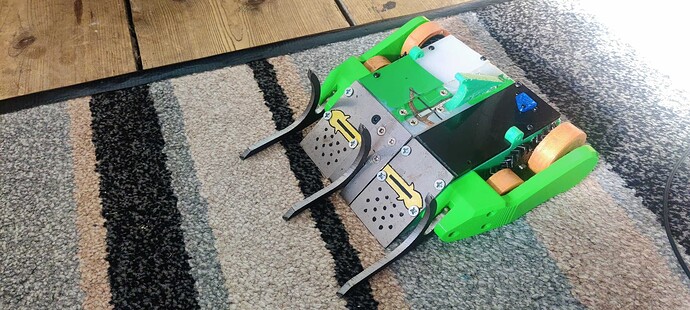

We’re back, because I’m impatient… and it’s been a while! Some minor tweaks and touch ups were made to the CAD since the last post, including moving the magnets behind the driving wheels. The 2025 events calendar has shifted around too, but my planned June completion date, initially for Rapture, is still on schedule, as I’m now signed up for Battle in the Burgh.

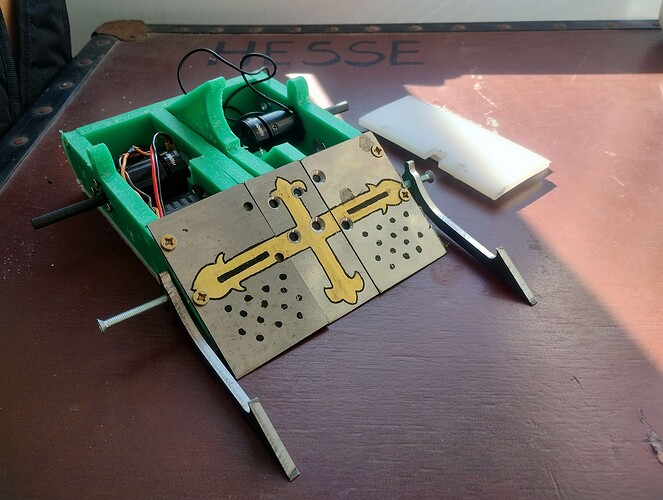

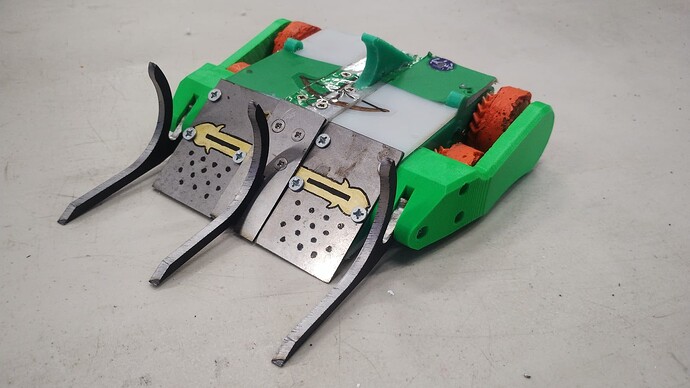

The first major update would be the hardox parts. I got these back in February. Yes, I did go with hardox, and @morgan_ls’s tipoff is legit: Crossblow V will have 2mm hardox wedges in both it’s regular, and anti horizontal forms.

Quite the armoury.

Shout out Stewart Agricultural for a very precise end product and being super easy to work with. You can also see my experiments with pain pens for the new-look Crossblow face - the robot has gotta have some personality, though this will be a little obscured by the TPU wedgelets.

The next major update is to the internals. I have fully committed to a switch, now, and shelled out for the Repeat Max V2s and BBB ESCs as well, since the Mars range is currently out of stock. I plan to shaft swap one of the motors, though. Barber Surgeon has a V1 Repeat Max that will need a longer shaft for the new design, while Crossblow will need both motor shafts shortened.

Since then, I have been into the hacklab to cut some parts from old offcut material I have lying around, but the bulk of the frame was done on @Hoppin’s CNC, looking mighty fine indeed. The holes to screw in the wedge have always been a bane of previous Crossblows, so this time I made a point of doing them properly, on a drill press, and using some printed guides to get the holes in exactly the right spot.

Current Progress.

All looking good so far - next will be finishing the lifter linkage and fitting the prints from @ForkliftCertified. I’m currently racing @Caleb to see who can finish their Crossblow first - no, I will not provide context. Look out for wheel moulding, soldering, and passing POM in the next update!

They love a nicely machined ass - courtesy of @hoppin. New die-cut stickers from PrettyGoodStickers.

super excited to see this at burgh. will be very fun!

The Build: (part two)

First on the docket was to cast some wheels - my first time doing this, thanks to my sidequesting in omni-wheels over the last couple years. The moulds and hubs were printed in TPU, and the 35A two-part rubber was sourced from DWR Plastics. This was chosen because I found a great looking liquid pigment (though I did consider Mica Powder) on the same site, one I think used by @hhills on one of his builds. I was keen to have orange wheels to reflect the original intended banebots wheels for Crossblow 1, and because green, white and orange is a colour palette distinct from Boom Zoom and Frog.

Demoulder? Nah, Vaseline.

The result wasn’t bad for a first go, but there’s room for improvement. I got the mix wrong on the first pour (the ratio was a nice, round, 100:16), and the mix bubbled, getting rubber in the gear teeth in my attempts to fix it. A syringe would also be a great idea for when I do this again!

Messy.

Next was a very smooth shaft swap - Barber Surgeon 4 will need to have a longer shaft on it’s weapon motor, so I swapped the shortened shaft from the Surgeon Repeat Max V1 into the Crossblow V v2. The shafts are identical in all other ways.

Motor Surgery

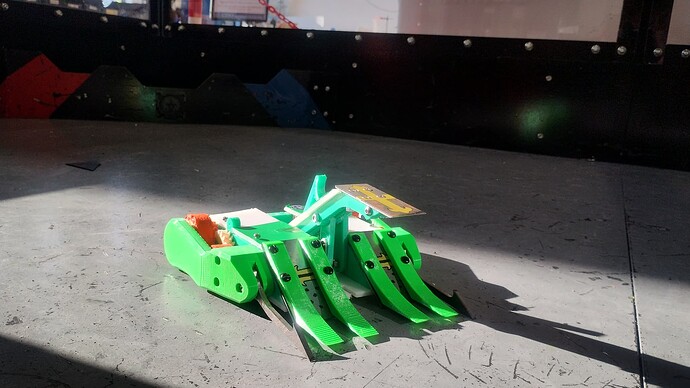

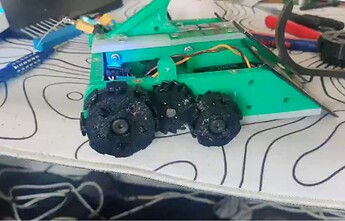

What followed was a straightforward creation of a wiring loom, and fitting the remaining TPU prints from @ForkliftCertified. Everything was pretty smooth! Long shoulder bolts into recessed square nuts secure the wheelguards, and the wheels ran on M6 shoulder bolts and Ranglebox nylon bushings. Everything seemed to rotate smoothly, although the fit was a bit tight. That said, it comfortably passed POM on 8th June.

Love the aesthetic, matching the tabard design.

There were a few things to fettle and tweak though - dialling in the transmitter mixes, testing the self righting, and fine tuning the weapon. I’ll cover the inevitable last minute gremlins, and the burgh event report in the next post.

Stagefright:

Despite a lot of prep, as the week of the competition loomed, a few last-minute gremlins reared their heads. While setting up the weapon mix, I began to have problems with the lifter sticking. I use aluminium ‘servo-saver’ horns, with large, horseshoe-shaped springs absorbing load from impacts. The sticking was causing these springs to deform, creating significant slop in the lifter mechanism. I was using new, smaller servo savers for this build, as there was no space for the tried and tested larger variant. There was further sticking in the drive - despite smoothly passing PoM, the left side would now only run 180° before locking up. Worse still, the receiver had stopped working completely.

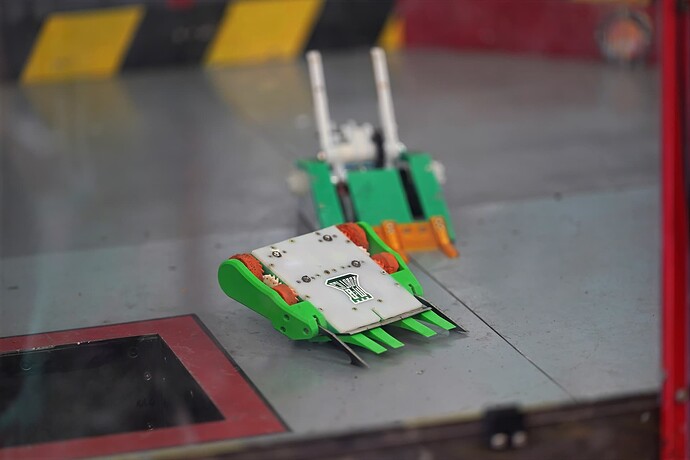

I had also run out of time. In the days before Burgh, I had some prior engagements down in London and Chichester, and so dropped by the University to see Garfie. Together we were able to determine that it was the receiver that had died, and not the BEC, as well as trace the drive problem to the motor covers - they were too thin, and had deformed against the packed wiring. sticking against the drive motor. The offending cover was removed, and the wires zip-tied down. We were also able to take some beauty shots in the Chichester arena.

We recorded a ‘Thunderbirds’ launch sequence, raising it from the pit.

Prodigal Son:

Arriving to the venue early on the Sunday, I was able to borrow a transmitter and receiver from Alex Mordue, and swap in a rush-ordered aluminium servo horn from Amazon. There was no clear blockage or stiffness in the lifter mechanism, so I hoped that taking the new servo saver horns out of the equation would lead to some success.

This is Crossblow’s first time competing at Burgh since 2019. Credit: Team Triforce.

I passed safety, and was very please with my draw - Babrog, Sabretooth, and Limiting Factor would mean an opportunity to test all three of my setups - forks, wedge, and anti-drum. I loaded into the box for my first match, relieved to be ready.

Winning the ground game. Credit: Team Triforce.

It was a fairly even match against Babrog. The robot, with it’s new magnets and drive setup, drove on rails. It was buttery smooth and went exactly where I wanted it to. I was also pretty happy with the new fork setup - I felt as though I was winning the ground game more often than not, but unfortunately, the lifter would not fire once throughout the match. As time began to expire, Eoin found his opening and tipped me over.

Normally, this wouldn’t be a problem - the shark fin is designed to allow the robot to right itself by charging into a wall, but the tip of the fin - which was supposed to be just ahead of the centre of mass - had ended up just behind it, causing the robot to pitch forward. With no weapon, I had no way to adjust the fin’s position, and was swiftly pitted. Nevertheless, I came away in high spirits with only the weapon to repair.

Welcome to standing-up school. Credit: Team Triforce.

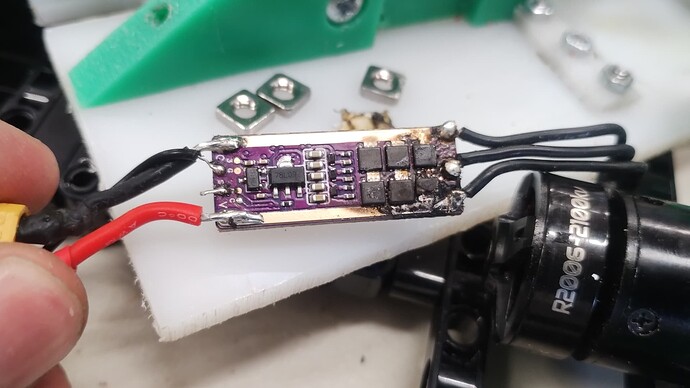

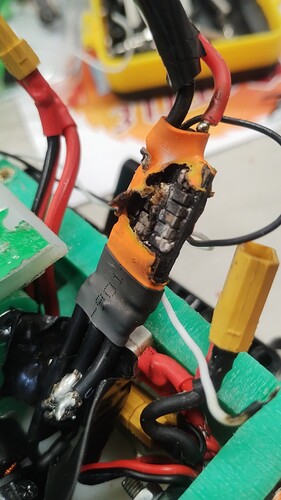

Or so I thought. Upon powering on the robot in the pits, to do a quick systems check, and before I had made any inputs, the left side ESC began pouring thick, white smoke, and I quickly depowered the robot and removed the battery.

Welp.

The cause was unclear, but I didn’t have time to investigate too thoroughly. there didn’t appear to be any shorts in the circuit, and so I sourced a replacement ESC (A Mars AM32, rather than a BBB Brushless) from Mark Smith, and got to work. The repair resulted in a rather lazy left drive side, but after a setup change, I made it in for the match with Sabretooth. I had also replace the aluminium servo horn - which had immediately stripped - for the servo saver again, as at least I could expect some weapon movement from that.

Fight Two. New Setup.

The drive was very limpy, and with Sabretooth either struggling to translate or keeping distance, the fight saw very little contact. That said, there was a lot of weapon wiggling, and the previous stickiness seemed to have cleared. I eventually lost mobility and was counted out. This was due to the right side motor cover, that I had left in place, deforming in the same way as the left.

On looking over the robot, I noticed how ‘toasty’ the drive motor coils were, and assumed that this had been caused by the fire. I sourced another motor, from Mark, and performed another systems check. The Mars ESC erupted in flames, (this time with the first input).

Wise words.

This put me out of the competition. Though the two first may have been unconnected - the wiring repair was pretty rushed - I couldn’t rule out the possibility of either a short deep within the loom, or that the tight mesh of the drivetrain (with the largely removed, but still present, PU overspill gunk) was overloading the electronics, and intended to nut-and-bolt repair the robot at a later date.

Toasty coils.

Literal tongues of flame.

This unfortunately meant not getting the opportunity to test the drum setup as well. But regardless, a huge thank you to the support of everyone who got this into the arena, and the BITB crew for running another fantastic event. Still my favourite, atmosphere wise. I came away strangely optimistic - the drive had felt so good in the first fight, and the weapon had been smooth in the second. Now if only they could work together…

The unused anti-drum config.

In Pain (with an ‘S’):

At this point I requested to be demoted to the Rapture reserve list. My entire July was to be spent on a heritage project in central Spain, leaving me without the time or money to give the bot the attention it needed before Colchester. Enter @Hoppin, who graciously offered to take a look at the robot while I was abroad. What follows is all him.

Changes made:

- Remoulded wheels with an adjusted Mod value: 19, instead of 19.4, for a looser mesh.

- Switch replaced with link, as it appeared to have stopped functioning. New lid cut.

- DMOND 86kg servo replaced with a 50kg one, as it appeared to have stopped functioning.

- Burned out Repeat Max motor and drive esc replaced.

- General wiring checks and QoL.

And I’m sure other things that I’m not aware of. All this is to say that Sion is a true gent, top guy, and complete sportsman - especially given that I’ve been restored to the main competition at Rapture and am in his heat, along with Boom Zoom and Upcycled.I’m incredibly grateful for his time and generosity, and without him, Rapture would simply not be happening for me this year. It will be run on minimal spares, so I don’t have high hopes for a deep run, but am excited for the weekend. Here are some photos of his work:

That’s everything for now. I’ll be back after Colchester with a report and some details on the planned updates!

It was great to see Crossblow in action at BITB, shame about the gremlins but it was really well put together. I do have some footage from Crossblow vs Limiting Factor at Burgh! Ok, so it looks suspiciously like Attitude Adjuster with a Crossblow sticker on the top, but it still counts, right? ![]()

Can we see the Plunderbirds intro?