(Okay, not really. This is the first formal build log I’ve done for DJ2, but I couldn’t resist the reference!)

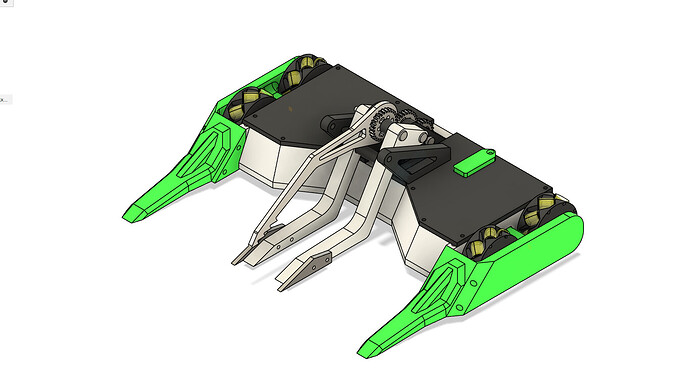

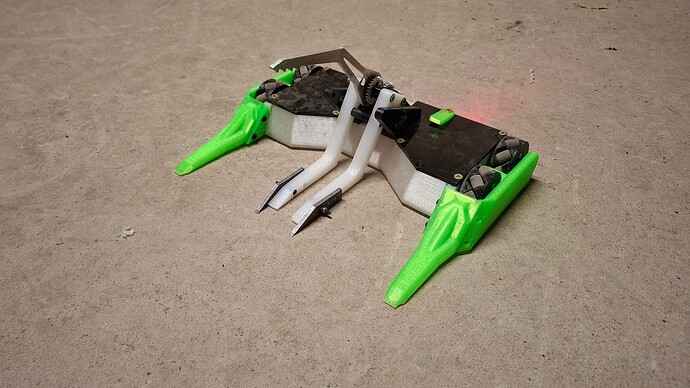

I’ve had some R&D work going on in the background for DJ2 since around late August in an attempt to improve the weapon system on it. Here’s a summary of what I’ve been getting up to so far.

Quick recap - currently, DJ2 runs a Econ 34RPM 25mm gear motor, which boasts an insane gear reduction for not too much weight (around 100g IIRC). The problem with this gearbox is it is a spur gear reduction, which means the gearbox is relatively fragile. A suffficiently powerful backdriving force (i.e. a vert impact on the arms) can and has sheared gear teeth - this cost me in the fight against Han the Hammer at Rapture, and has resurfaced at most of the events I’ve taken DJ2 to since then. Ideally, I’d use a pololu 37mm gearmotor or a planetary gearbox on a brushless motor, but these weigh a fair bit more, which would make getting in weight difficult as I need 4 drive motors for the mecanum setup.

This led me to discovering cyclodial drive, which is a way of getting high reduction in a compact space, and a lot of videos online use 3D printed designs mounted to NEMA stepper motors for robotics projects. I thought I’d try to design a cycloidal gearbox to mount to an Overlander 2836/08 1120kv motor (which I’d already picked up a couple for PMXL V2), as this could in theory solve the weight and space issues that other commonplace solutions would have.

Cycloidal gear animation from the wikipedia article. Green is the driven input, purple is the output.

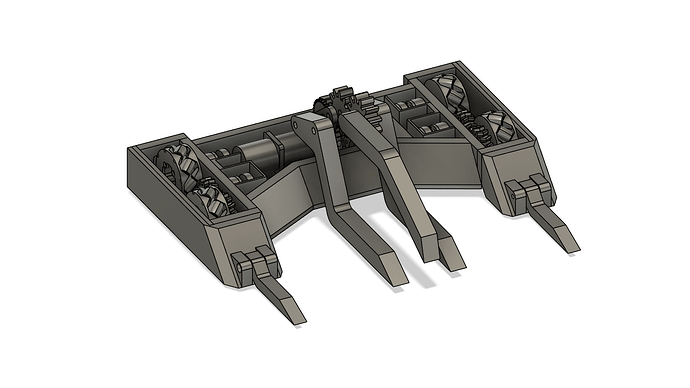

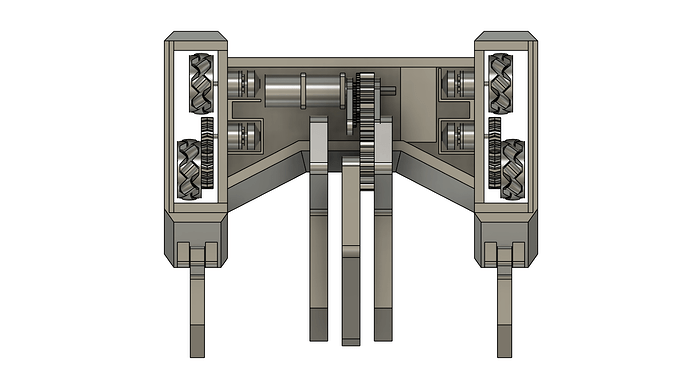

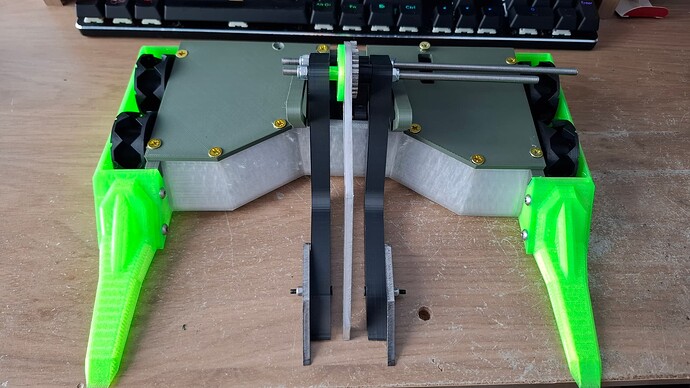

A cycloid is the shape you get when you trace a point on a circle as it rolls along a surface. A cycloidal disk is the resulting shape when you do this for a circle rolling along the circumference of a larger circle. The gearbox contains a number of pins that is 1 greater than the number of lobes on the cycloidal disk, and the cycloidal disk is driven with an eccentric cam. This causes a slow rotation of the cycloidal disk, with a reduction equal to the number of lobes on the disk. If I design a gearbox with two 14:1 stages, I can achieve a 144:1 reduction in a small package, which would bring the selected brushless motor down to 131RPM, much faster than the current setup for snappier self-righting but still (hopefully) in the controllable range. With a further 25:14 spur gear stage from the gearbox output to the weapon shafts, this should hopefully result in a more powerful and maybe more robust weapon system.

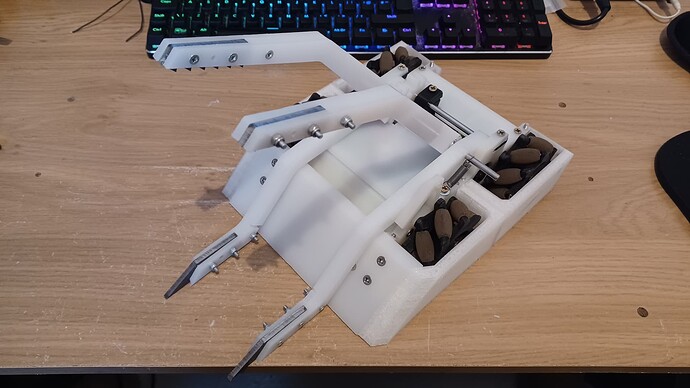

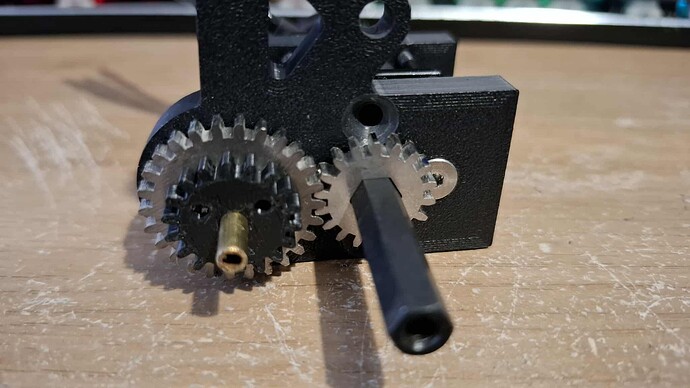

Following this tutorial, I set about making a prototype gearbox, for now mounted to a N20 motor I had lying around. This version uses two disks offset at 180 degrees to minimise vibrations that will occur from the eccentric mass, which is a common thing to do in cycloidal gearboxes. The output shaft is just a prop adapter for a brushless motor I had lying around.

This works great as a proof of concept, but has big issues with transferring torque, as the stator pins flex outwards. I also noticed the output rotation wasn’t smooth.

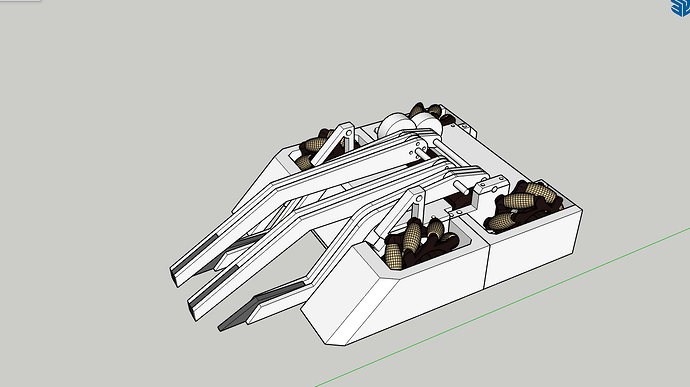

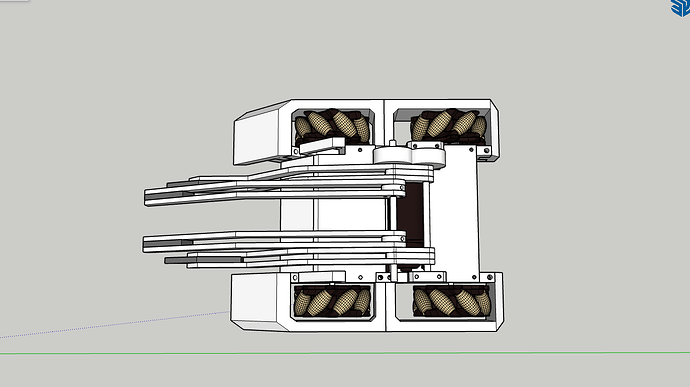

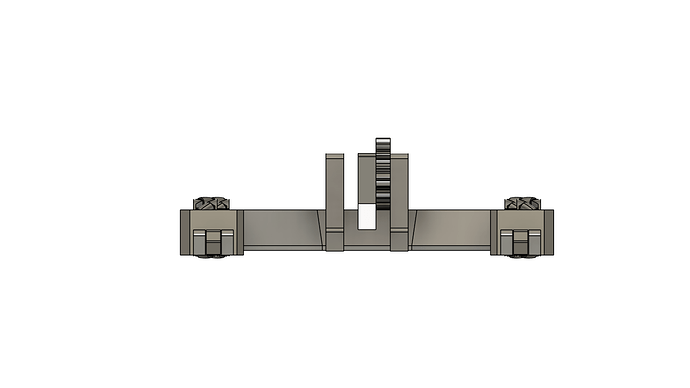

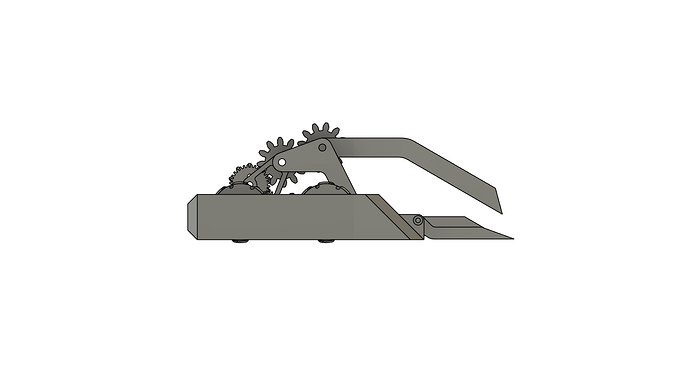

This is where I’m currently up to, with V2 of the gearbox. The pins are now connected together so that they’re more rigid, and the output shaft is a 6mm steel rod which will be keyed with a flat into the output disk. The whole thing is designed to be manufactured out of 3mm and 4mm plates, which will let me take advantage of Lasered’s aluminium cutting services. The gearbox is also mounted to the 2836 now. Still waiting on some bearings to arrive before I can test this version. Other things I need to work out is how I’ll mount the gearbox in the robot. I’ll likely face mount it, and will probably need to support the brushless at the back somehow. The brushless motor shaft is longer than I need it to be (you can see the smaller diameter spacer in between the brushless motor and the main gearbox), so I could push the shaft back out the other end and support that with a bearing.

Is this a productive use of my time? Will this thing even work? Who knows! But it’ll be interesting to see how it turns out.