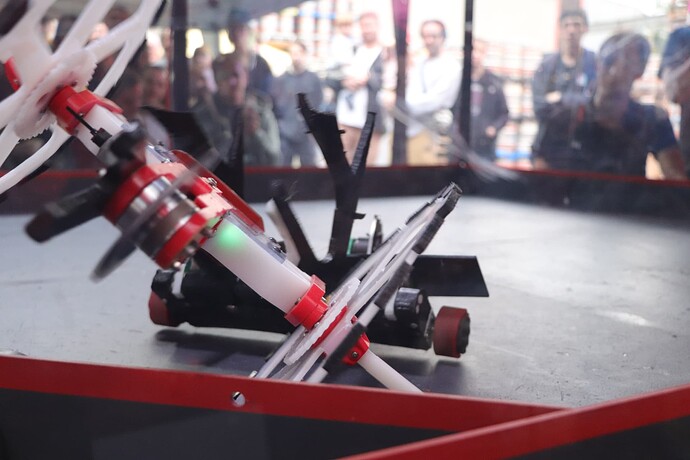

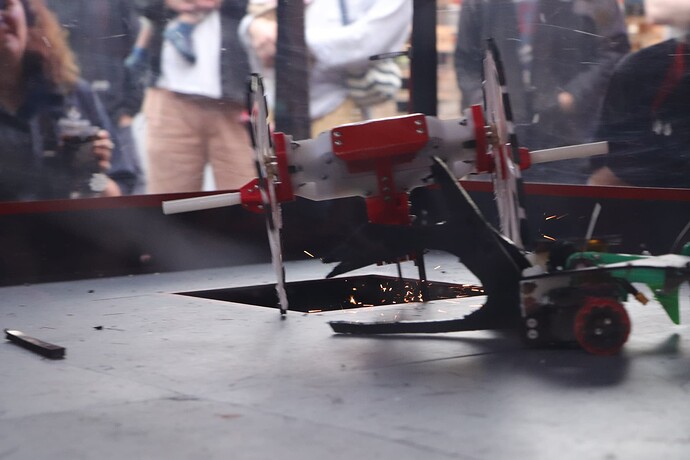

hello! figured it was about time i did another build diary, now Dolos for a while has been pretty stagnant design wise, i mean if it aint broke don’t fix it right? well after war in the Wirral there was allot broke and allot needed fixing and it taught me allot of lessons

(apologies in advance for spelling or grammatical mistakes, those are really not my strong suit ![]() )

)

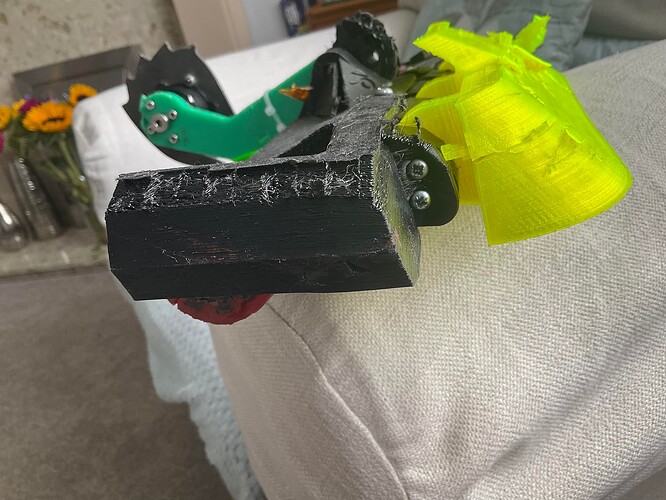

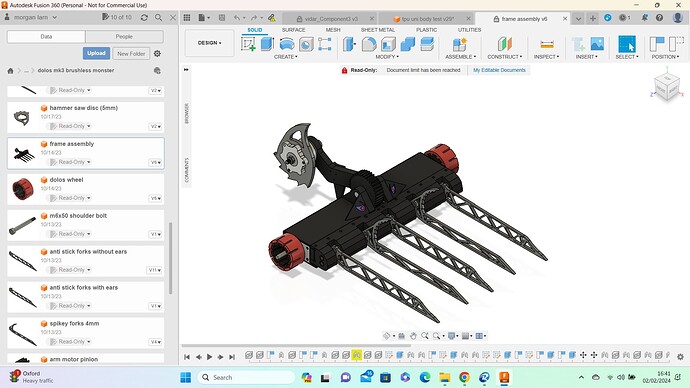

dolos prior to war in the wirral (with its old anti horizontal wedge)

firstly to not always expect it to do well, prior to this it had had 3 top 4 finished and a top 8 at ratpure so i kinda threw it together with spares and not allot of thought and figured id have a decent shot, and instead got back a pile of bits haha

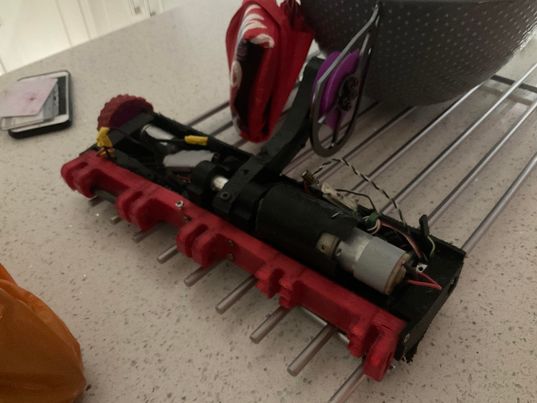

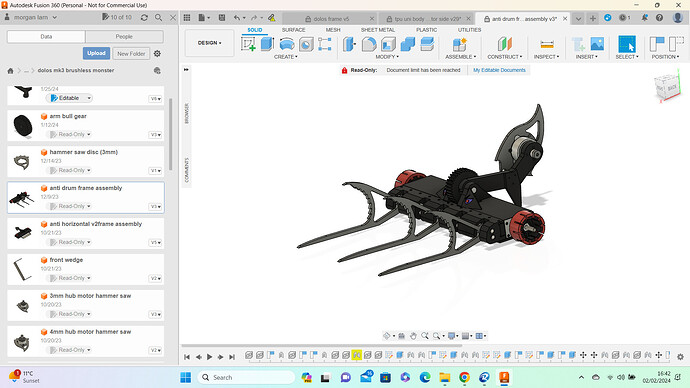

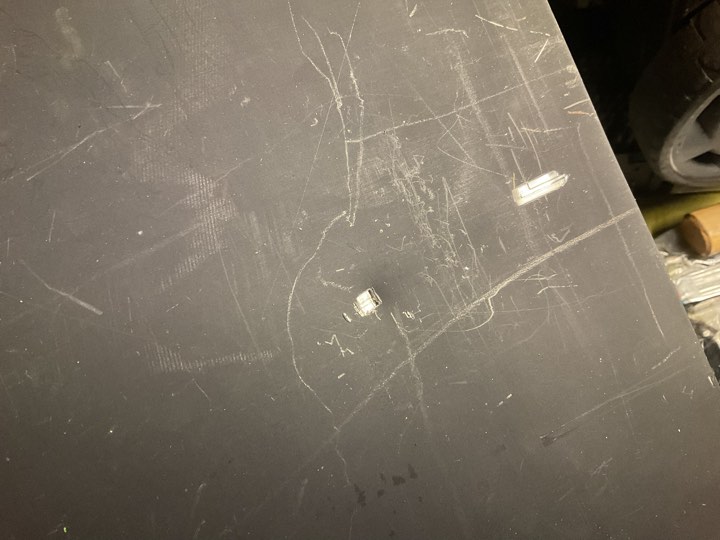

dolos after war in the wirral

all but 1 of the motors on the robot were out of action by the end of the day, front end was wrecked and the blade twisted

it highlighted allot of issues id been having with the bot and ignoring because “if it aint broke dont fix it” these being the lack of drive reliability and power, it had previosly been able to get away with just using 22mm bbb motors and exposed wheels but as of late its been killing allot more and breaking them, and frankly getting out pushed but spinners is not fun haha so i wanted to go to brushless drive

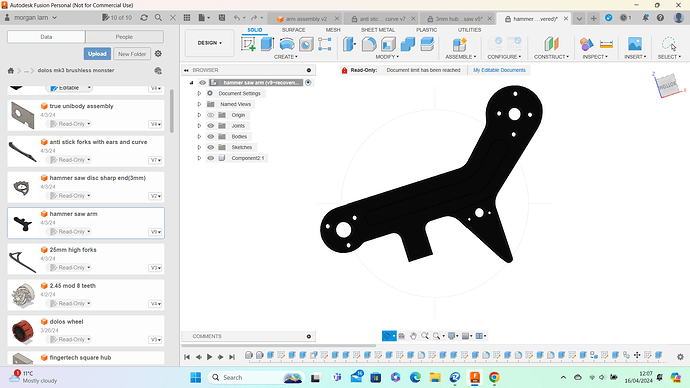

the other thing that i really wanted was a more reliable weapon, the hammer arm itself has always been pretty bomb proof, ever since i swapped to a old cordless screwdriver after subterranean its had loads of power and only been killed twice in like 20 matches, the disc however has always had problems, this mainly stems from wanting to keep the insides as tiny as possible to allow for more width. this meant the motor was stuck out on the arm with a belt drive leaving it very exposed to any spinner that breaths on it, often ending up with a dead weapon going into fights which sucks when that’s your main way to deal damage

i also felt i finally needed to step away from the screwdriver motors, although they have been nothing but reliable they are also large and heavy and very exposed with no real way to put them inside the robot, so these will be replaced with a tried and tested method from the other hammer saw bots with a 3:1 reduction to a fingertech mega spark

that and seeing how much success saw loser has had with there hub motor i figured i may as well try and emulate that success

also the front end failed pretty badly, the first fight baby dead bod cut almost half the posts on the front and then they all let go vs ice breaker, making for the first time a fork had been ripped off since its first even

finally i also wanted to sort out the sticking issue, as rules have changes its no longer as good as it once was, so making some proper forks that wont get stuck is a must

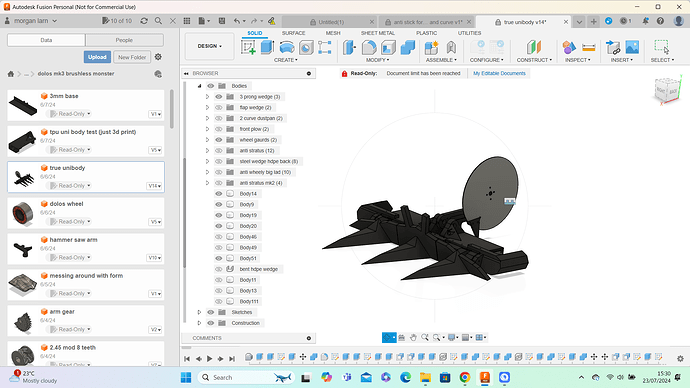

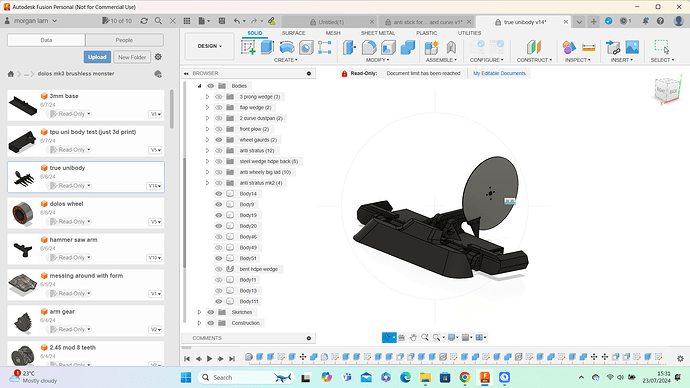

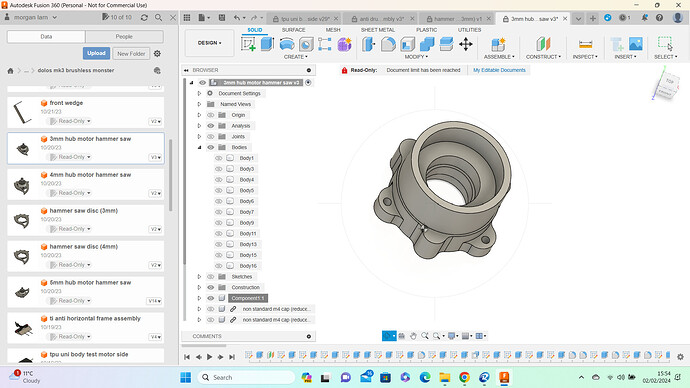

with those deisgn criteria set out i started on the cad, i quickly realised however that weight wise it wasnt going to be possible to keep the same dimensions, dolos has always been a wide boi to help to capture opponents but i had to do the unthinkable and chop 20mm off its width to a measly 280mm wide. this however freed up allot of weight for the rest of the bot

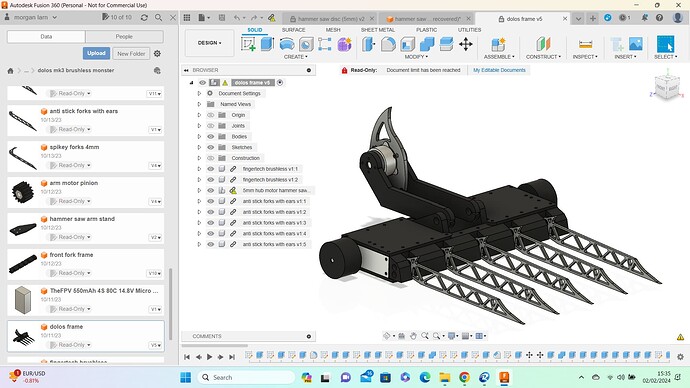

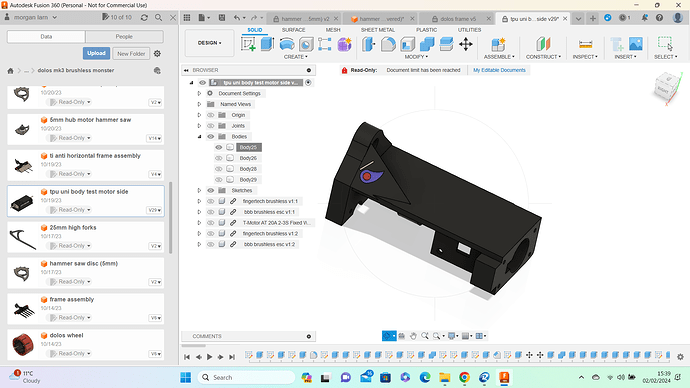

first rough cad

with this first cad out the way i found i was still way overweight, the old method of screwing plastic plates to the tpu frame was not going to work, i also didnt really want open lids, they always seemed to let me down when it mattered with messy wiring and wiggly links

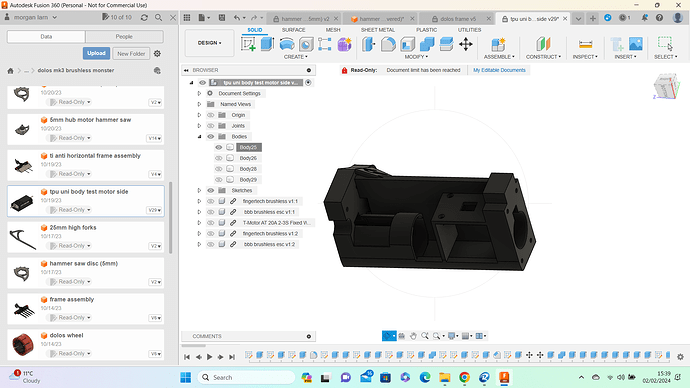

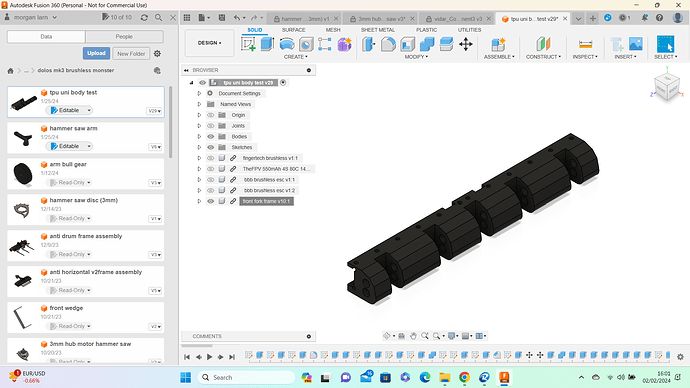

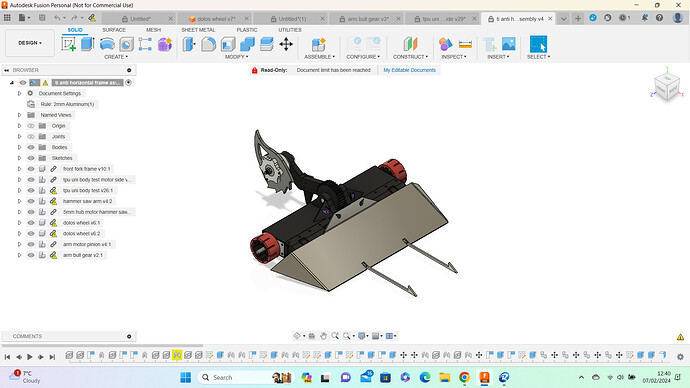

so i decided to try and make a 2 part tpu uni body

this being the motor side for the hammer arm it makes it a very compact and lightweight package, everything bolts to these pair of body’s with the front rail and bent baseplate and rear armour providing the rigidity of the whole bot

the drive motors are fingertech megaspakrs with the hammer arm being the same motor on a 3:1 ratio with a 10mm aluminium dead shaft support the hammer arm

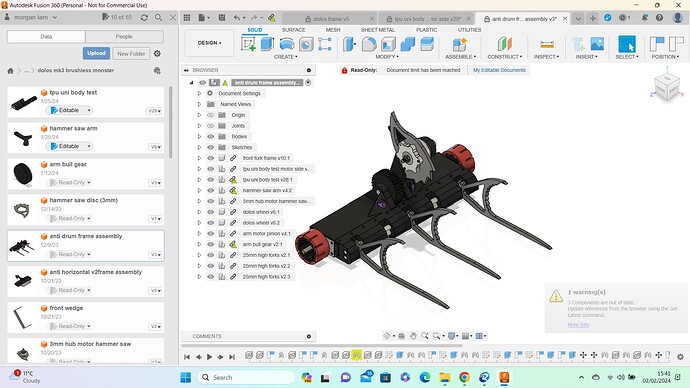

this meant it could be in weight, looking like this

(pictured with its anti drum set-up)

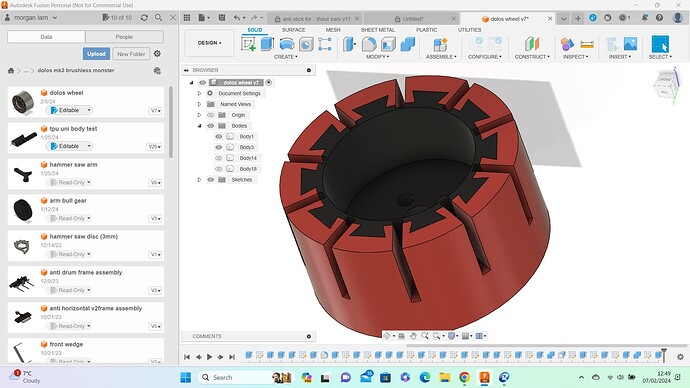

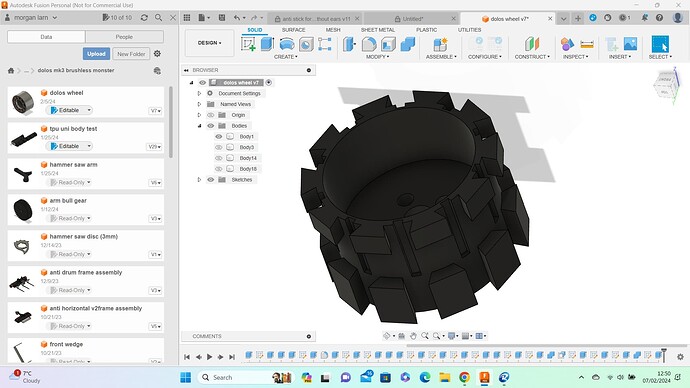

one of the more noticable changes is the wheels, on previos versions of dolos these have been machined hdpe with belt screwed to them, or tpu with the same belt, i recently went to cast wheels but they all had the same issue, when hit they would either fly off or break the gearbox, or both

so i designed some “flap” wheels, i designed a version of these for my antweights years ago and they appears to work well, being made from pla it allowed for a part of the wheel to fail and break away without loosing the rest of the wheel, i took this a step further with this design and made them tpu and cast rubber, allowing the flaps to flex out the way of any incoming hit preventing the loss of the wheel and limited shock to the gearboxes, it also had the added benifit of making it much harder to get launched from a side shot

these consist of 10 segments each with there down dovetail to hold the rubber to them

the rear has its own set of dovetails to prevent any one hit from compromising the whole wheel

they will be mounted with the fingertech mounting plates and the motors themselves held in with a 1mm aluminium lasercut mounting plate, this is screwed into the tpu, although the motors are mainly constrained by the tight fit into the tpu itself

with the body and arm system making weight i then had about 2-300 grams left over for the hub motor

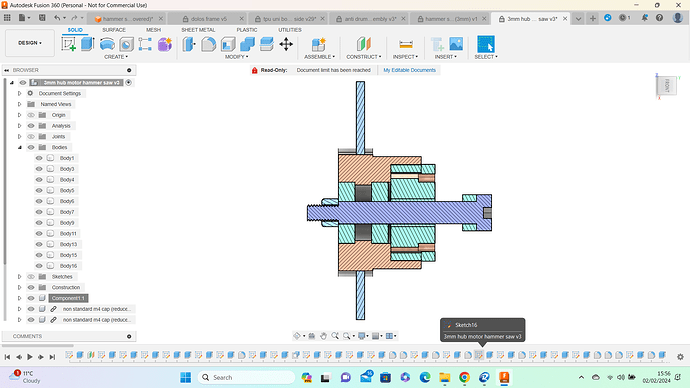

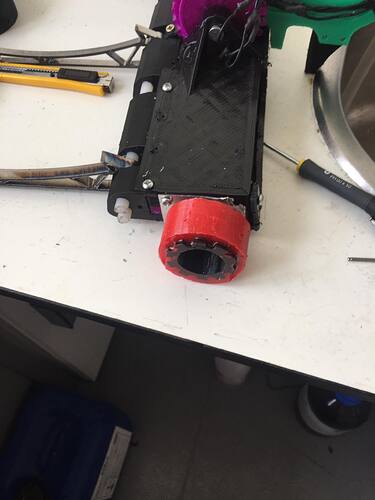

now ive built them before (see my build of yam) and a much older bot in chaac this was the first hub motor ive made without dual support and for a hammer saw, as a result i wanted to ensure a relaible spin-up and strong system, for the motor i went with one of zephyrus’s old weapon motors, a 3520 (2808) which delivers insane beans for its size and being a low kv (only 850) meant i could have a large diameter weapon with a relatively small hub,

ill go on a bit of a tangent first about why i wanted a large diameter weapon for dolos, with bots like attitude adjuster and saw loser there smaller weapons allow them to deliver a larger punch than dolos but dont have the range to go weapon to weapon, previos incarnations of dolos have been able to reach past verts and snipe belts as well as going weapon to weapon with some smaller horizontals. the trade off being that you cant really have a large diameter hub motor without sacrificing something else to be able to be under the tip speed limit, to this end dolos has a pretty large 149mm (up from 145 with the old weapons) diameter weapon with a relatively low kv motor, meaning a slower spin-up but the larger diameter should allow it to sneak shots against smaller verts and mabye even some of the bigger ones at the right angle. this is not to say i think my design is better than theres, but i think they both have advantages

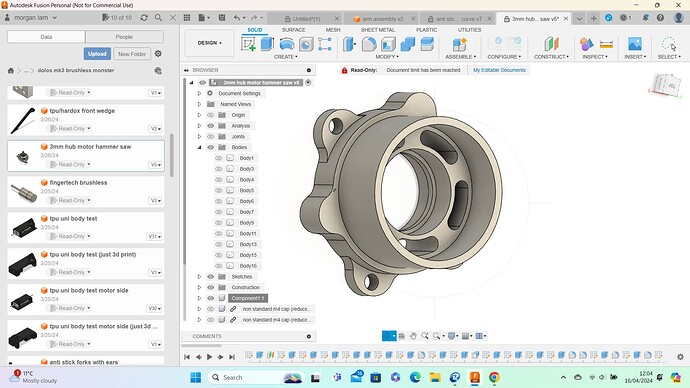

anyway on with the hub motor design, the heart of the whole design is the cnc aluminium hub

the lobes key into the weapon with 3xm4 bolts holding it to the place making swapping the weapon a hopefully less painful experience. it also means i can run thinner weapons to claw more weight back for alternative set-ups. it then uses a pair of 22x6x5 bearings on a 6mm shoulder bolt

this should keep it pretty reliable

annoyingly the motor i had choses had a very weird 11mm od beairngs in it, requiring me to drill it out and press in a 11-6bushing. which took most of the slack out the system

this came to a rather meaty 270 grams, with close to 250 grams of spinning mass in its heaviest configuration, 150 of which is the weapon disc

the hammer arm itself has also changed, going from 15mm thick to 8mm, mostly for weight but mainly for more flexability, looking at strike point across the pond he got away with a very thin arm, im trying to replicate that

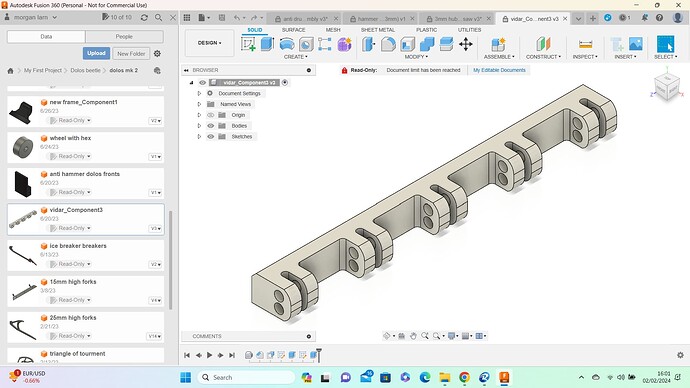

next on the to do list was the front end, previously this was some rather small tpu hinges that kept the forks on

i decided to redesign this entirely and go to a much beafier design

although slightly heavier i felt it was well worth it to keep the forks on the bot and protect the fork shafts

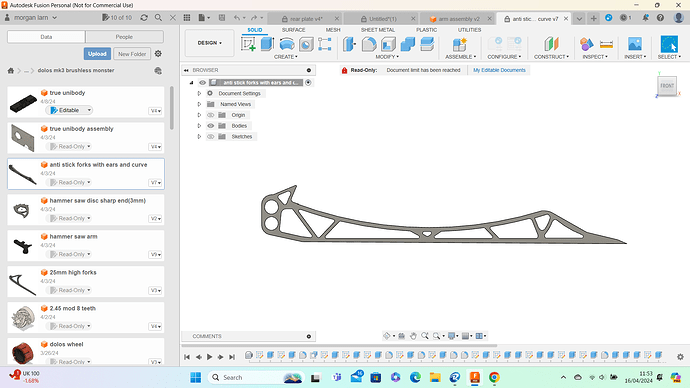

with the main design sorted i turned my attention to the forks and set-ups

dolos has always had allot of set-ups, which i love to have means i can adjust the bot to fight any opponent, this version is no different with 5 set-ups

anti control bot set up (and anti vert set-up) running either the 5 or 3mm blade depending on if its a vert or not, in the case of a vert ill run hollow aluminium tubes over the hollow carbon fibre tubes

this uses the “bridge forks” which stop bots getting stuck as well as 2 “thumb” forks to catch and hold bots at the perfect distance from the hammer saw and prevent them moving too far up, these may be swapped to the bridge forks i case of verts to not give them an edge to hit

anti drum set-up

this set-up has been bomb proof on previos verisons, the forks are 5mm thick hardox with a very low front edge with a aggresivly spiked bucket which is matched to the diamter of a fingertech beater bar, the idea is the low front doesnt allow a drum to catch the tips of forks and then i can ram them into a wall meaning they get a face full of spikey forks, this either stops there weapon or causes them to flip over, having had great success with this against oubly and sweg

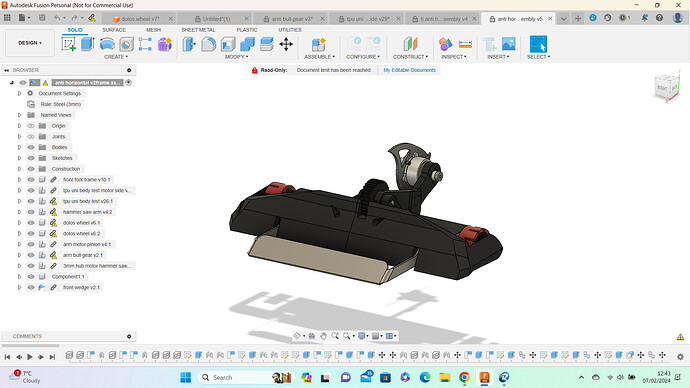

finally the anti horizontal set-up of which i had 2 designs

this one is designed for slightly smaller diameter horizontals or those which play ground game as it allows me to run a pair of smaller forks with break away edges if they get caught (inspired by minimiser) the front itself is a large bent peice of 2mm ti although pretty thin the shallow angle should allow it to deflect nicely

the second design is what im coining bunker mode and takes heavy inspiration from sawblazes anti horizontal set-up

running the thinnest blade (3mm) it frees up weight for a 2mm hardox front plow designed to deflect horizontals upwards and also to allow me to grip on there undersides, this is backed up by a very thick tpu front, each half weight 110 grams each of thick walled tpu, this should protect the body from all hits, as well as some wheel gaurds to prevent stray shot

i also have another design for the big wheeled bots, but ill keep that one closer to my chest for now

with the cad mostly finished i moved onto creating the bot

with almost the entire bot being printed it made creating it rather easy, although a massive cheers to rob (who runs boom zoom) for printing the fronts out and they are easily the cleanest part on the entire build as well as machining the arm

the main part i had to manufacture was the base and rear armour, this consists of a 4mm piece of bent hdpe. i didnt get any photos of this but i clamped the part between two bits of steel and used a heat gun to warm the plastic, then gearing gloves i bent i tby hand to roughly 90 degrees, was a little rough but came out good enough

next i assembled the hub motor, to do this i first covered both the stator and magnet ring in epoxy and then lightly sanded the inside of the magnet ring to remove any leftover glue

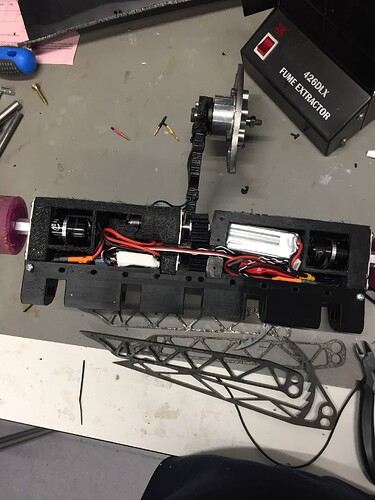

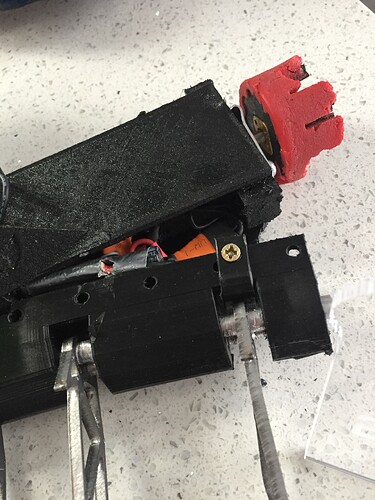

annoyingly i dont have too many photos of the build process but one slightly further along is this picture, missing the baseplate and rear arm support

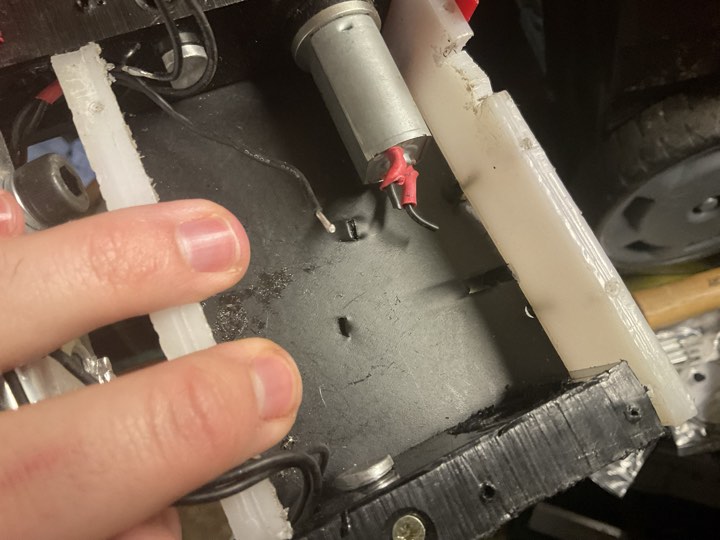

next step was the wiring, as you can see its pretty cramped, by some miracle it all went in rather painlessly

finally here is the finished bot

pretty pleased with it

did some testing with it as well to see what materials it was able to puncture (test took place in an empty garage with me hiding behind a 6 inch brick wall)

first test was against an old bot of mine with 3mm hdpe armour, managed to get through without too much trouble

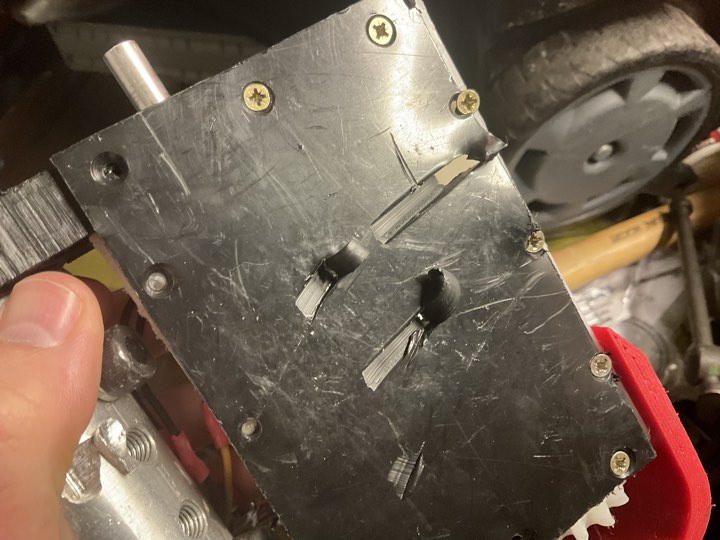

next test was a sheet of 3mm polycarb

as you can see it managed to puncture pretty well. took some force to get back out again

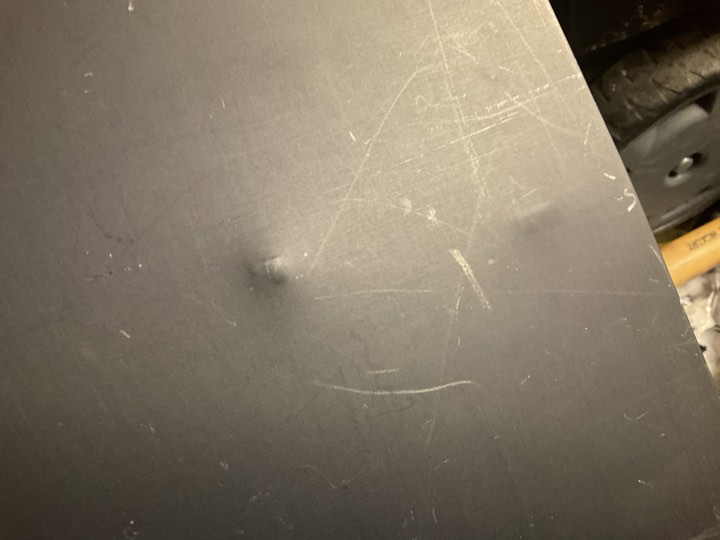

i next tried it against some 2mm ali

in nearly was able to breach this, and certainly breached my ear drums after hitting it

i also tested it against a big block of hdpe i had as a test dummy, managed to get over 6mm deep before stopping. so with any luck 5mm and below ill be able to breach

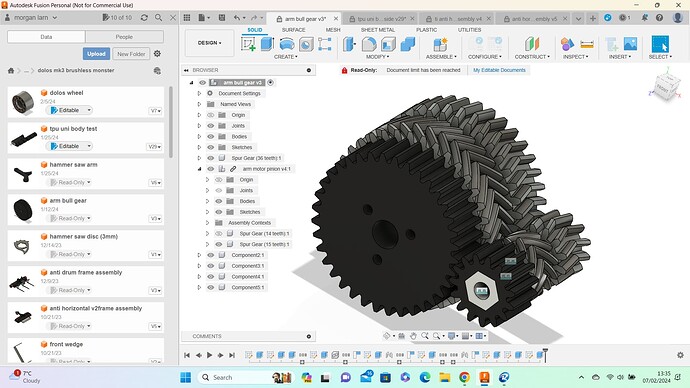

however these tests highlighted some issues that i will be addressing, mainly the arm drive is no good so on suggestions from a few other builders im going to a hellical gear and also with a slightly higher reduction (2.5 to 1 to 3 to 1) which should allow the arm to swing easier and prevent the gears from stripping themselves

the old gears vs the new ones

im also trailing a 45 degree and 15 degree helix angle to see which works best for the application

the other issue was the drive, with the way the weight distribution is now its much closer to 50/50 making it allot less nice to drive, going to try to remedy this with magnets and wheely bars. ill update the log on these as i go

once ive fixed those issues dolos mk3 should be ready for its debut at scouse showdown! thanks for reading

![Minibeasts In The East - LIVE Beetleweight Robot Combat [April 2024]](https://forum.bristolbotbuilders.com/uploads/default/original/2X/3/34230125e99782d7754ed3577a4902c2c8118f72.jpeg)