I cleared out a lot of stuff (CNC router project, couple of printers, my airbrush) and so naturally had to fill that hole with more junk.

In my previous build spaces I’ve always had a drill press, mill or both. Bopping holes was never really a problem. Since I live in a flat now with no other workspace my options were limited. I could have bought another traditional bench top drill for ~£100, drive to Surrey and rescue my large rusty childhood one (and have bits fall off my small silly car) or buy a cute PCB drill named after a curry and press gang it into service for robot use.

Naturally I went with C.

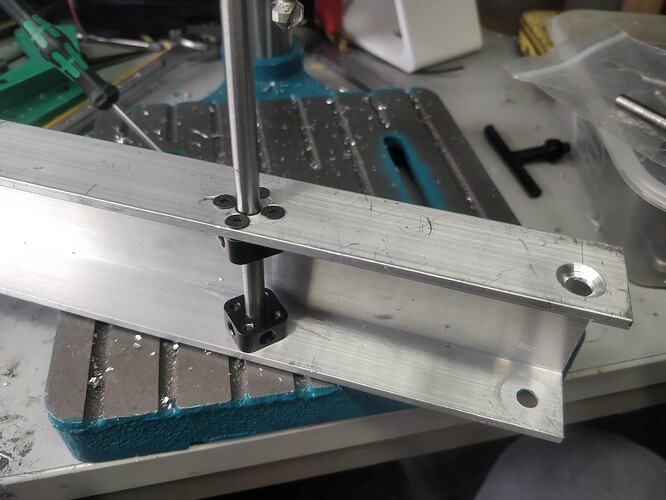

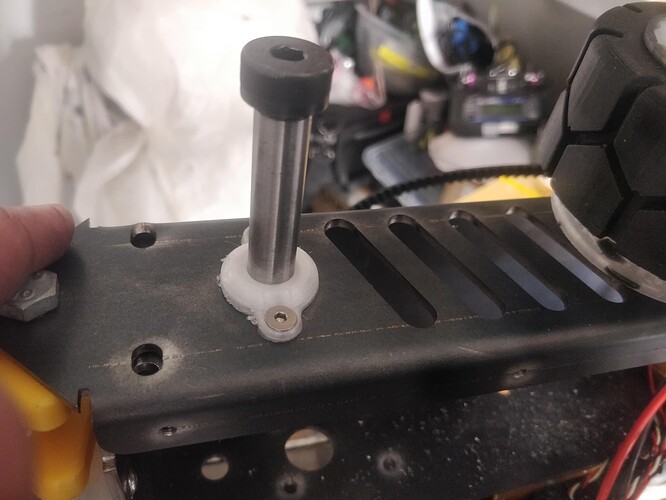

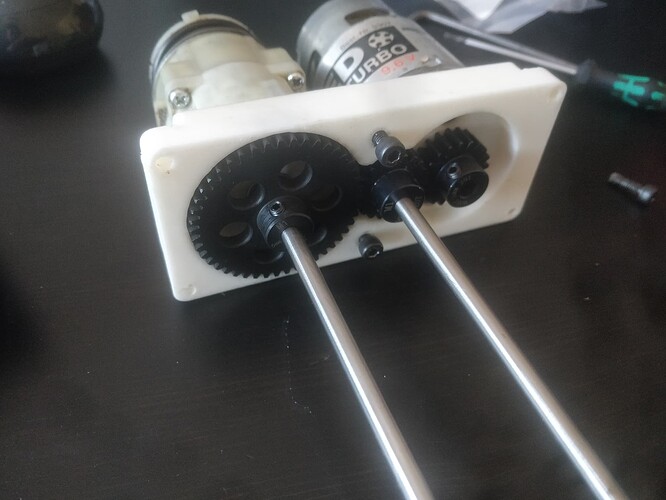

It has so far been a good investment and has let me pump holes quite happily in the aluminium arm and the steel gears. The arm has had some work done to it. I have slightly bastardized the Ranglebox hubs. Instead of holding a wheel or gear to a shaft they’re holding in the 6mm pin that is driven by the front link arm.

The little teeny tiny bubbie drill did super well with some serious abuse straight out of the gate. This thing is meant to put 2mm holes in fiberglass sheet and I forced it to pepper my dubious Chinese gears full of 5mm holes and 8mm counterbores. It wasn’t pleasant but it jolly well worked.

The shoulderbolts arrived and I was able to properly mount up all the wheels. I drew and printed these cute little mounts which just support and space the driven wheels.

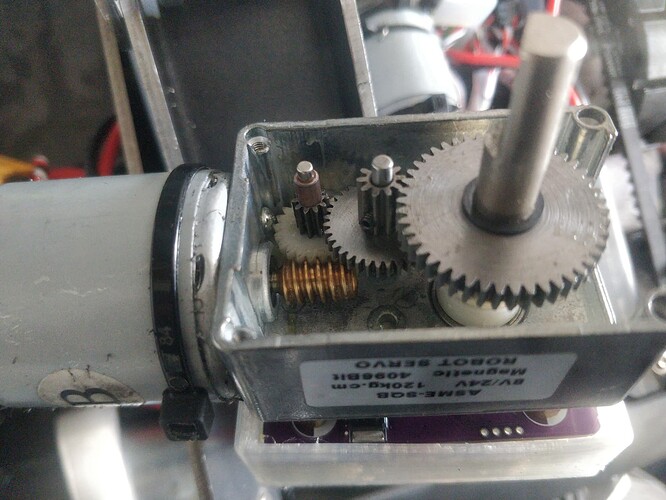

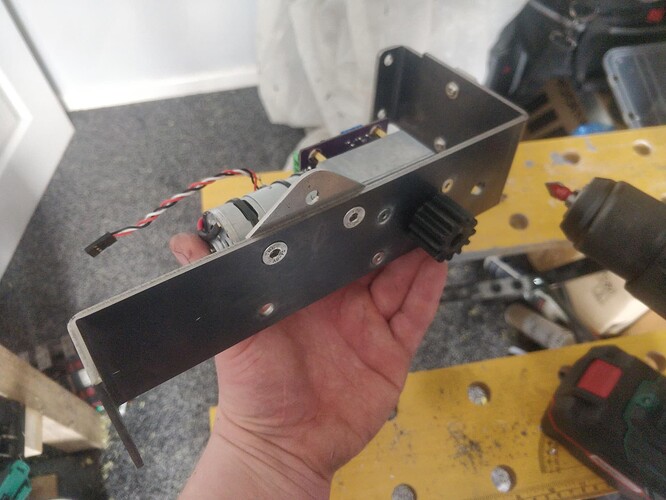

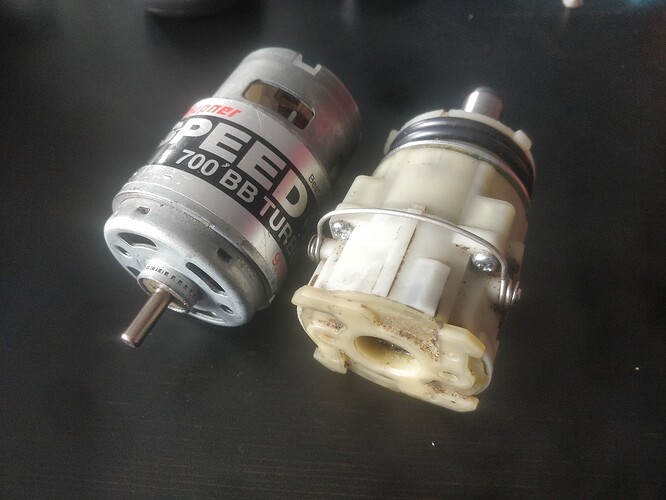

It was around this point (1 week to go! ) I managed to shatter one of the gears in the servo. Surprisingly it was not the plastic gear that went. It was the metal one just off the output.

Through a bit of spit and guesswork I worked out it was a 10 tooth MOD 0.6 gear. Luckily I’m a dab hand at bodging this sort of problem so I quickly had tracked down an RC car pinion exactly the size I needed. I bonded this and the other gear to the shaft with a liberal dash of loctite 638.

Dual servos were back on the menu! I had a huge headache trying to get them both matched in speed and travel. Though only purchased a couple months apart one was masses faster. Luckily they had adjustment knobs for travel and speed but it was time lost fussing about over them so they didn’t fight each other and eat more gears.

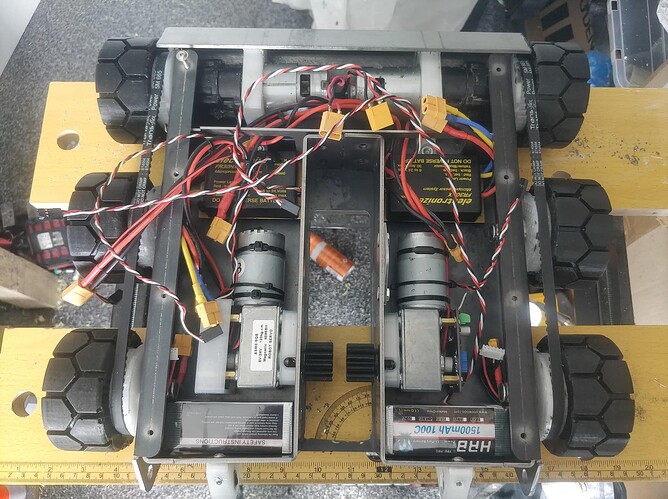

I also printed out a little covering cap that protected the bare control board and bolted up the locking bar mount tab thing. All the holes in this bent internal brace were countersunk at this point.

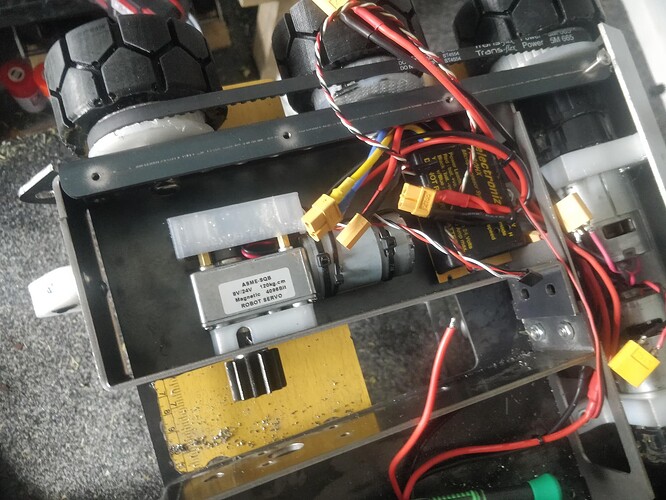

The wiring wasn’t too much of an ordeal but it wasn’t the most trivial task to keep it relatively neat. Wiring up two escs, a BEC and the servos somehow took an entire afternoon.

Batteries of shockingly dubious origin were acquired at this point. These are the absolute cheapest 5s packs I could find locally. On Amazon of all places! For £22 I got a pair of them. Low on capacity but sufficiently juicy with regards to current.

That is honestly pretty much it with regards to the build stages. Once it was wired and buttoned down it mostly behaved itself and I wasn’t having to solve awkward problems. I ran out of time a little but not too badly in the face of things. I was still drilling holes and such the morning of the competition which was fairly amusing.

On to the event!

I had a really genuinely chilled time which was fantastic. Weather held as well so I wasn’t having mild panic about water damage. Nice bit of chat with people too and there were some overly generous compliments about the robot (mainly the wheels!)

My first fight was against Barrog Doom in which I found myself stunningly outclassed. Having the drive in low was something done intentionally with the aim of reigning in oversteer and keeping it controllable for my dull reactions. It maybe was a bit too slow as I was outdriven at each turn and could never really get anywhere with the Irish behemoth. I felt that it was less of a fight and more Eoin picking the manner in which he won. Ultimately ended in a pitting.

CATastophe was next on the list which went the distance but ended again in a loss. Again feeling a little sluggish and that meaning the equally glacial weapon didn’t get to come into play. I think I was missing the momentum to push or bash and was losing out by being controlled and badgered. I was just unable to perform. Stupidly lost a wheel in this one due to the ole LH screw backing out under duress. It totally deformed the washer so it was done up with a certain degree of tightness. As it was the driven wheel that knocked the side of the drive out completely. Silly thing but easy enough not to replicate!

Third was supposed to be a rematch with Chris after our damp squib of a match from last year and we’ll be waiting again. He had unfortunately designed an automatic tyre removing device that doubled up as a robot and had run out of both wheels and inclination to continue. Instead I clashed with the wonderful Hover Bother which was about 70% motor by weight and about 60% batteries by volume. It is wonderful and quick and slightly erratic as a result. I had a bit more success getting in with the lifter but it was quickly struck with hammer blows from HB and something jammed. With an obscene amount of luck I was able to get HB beached on the ball pit (common phrase in combat robots) though I can’t say how much of this was down to me and how much was down to Hover Bother’s bombastic wall to wall arena tour.

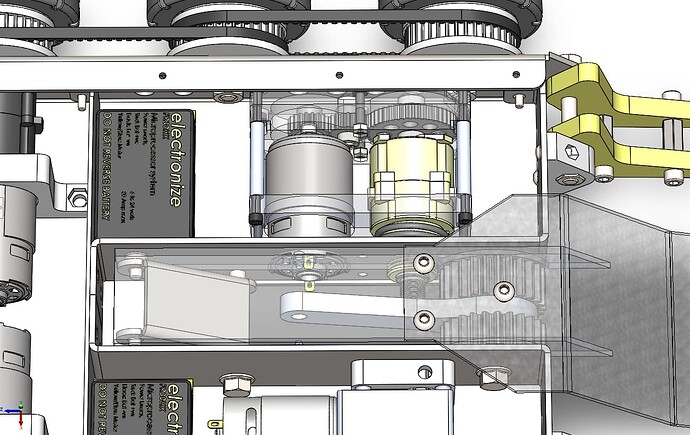

Deservedly out of the running now I just went in for a whiteboard. The lifter was in a bit of a crunch state so I just blanked it from my mind and went in not expecting to use it. I put the drive into ‘high’ just to see how it faired. I was in against Pizza Time and Easy Over. Pretty well to be honest. It was a little bit chaotic from my end but it was more in keeping with what I want going forward. I tackled, slammed and missed with Pizza Time but felt much more involved in the fight than just a token trundling alsoran. I ended the fight upside down and smoking which is how I often end a Saturday night and begin Sunday morning. The more “drive it like you stole” attitude I adopted was not kind to the arena wall or two old, hardworking overvolted 775’s and I finished up the fight with one making a very suspect smell and smoking rather ominously. Cards on the table I am surprised this didn’t happen sooner as they did not have an easy time of it. Harsh overvolt, large wheels and a relatively narrow wheelbase.

Post match inspection revealed incredibly sad servo gearboxes (though the nature of the sadness is yet undetermined), a rather pungent 775 placed at a rather jaunty angle split off from it’s gearbox and a concerningly puffy over discharged lipo.

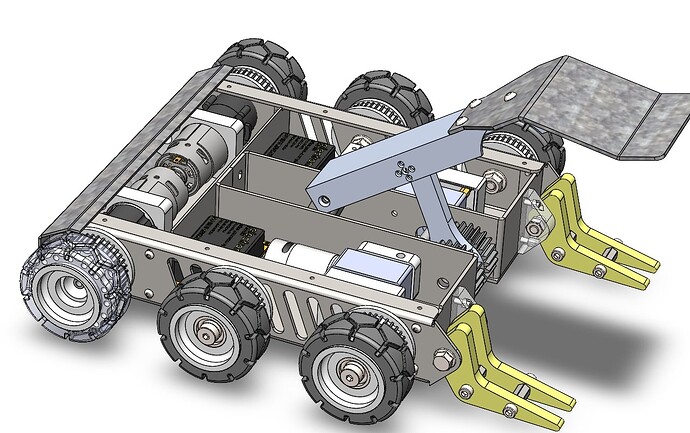

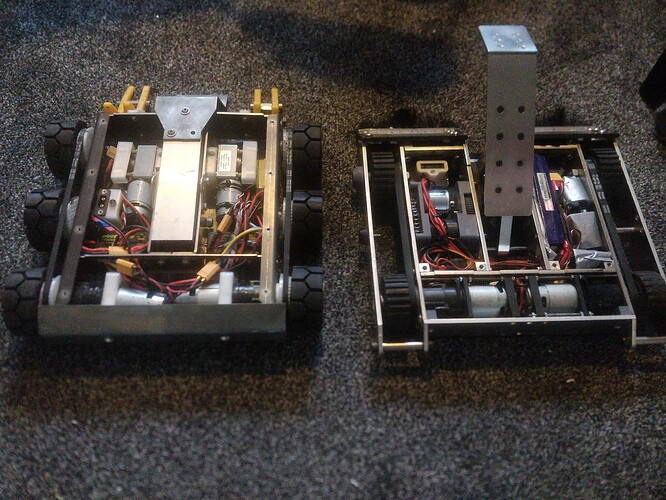

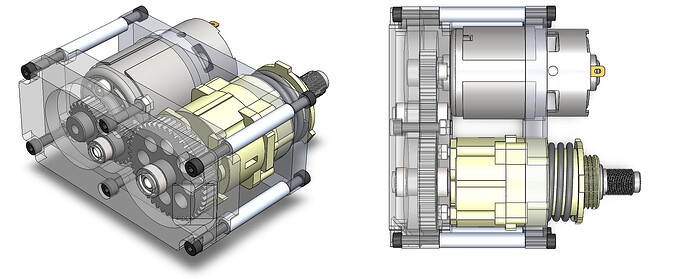

Overall I am pretty pleased with this build as it has been my first real scratch feather since 2017 I suppose so it was nice to get the feel back for it with my current year brain. The folded chassis worked super well and with the previously mentioned drive notes I am happy to continue down that road. New motors are a must and I will be revising how they mount to the gearboxes. I am toying with a printed clamp mount that an aluminium motor mounting tab interfaces with. Better than a few millimetres of rubbishy injection moulded ABS. The wheels were great and a lovely gimmick. I will be redoing these with a wider pulley so I can have a dual belt system to actually drive those pesky centre wheels and keep that beautiful 6wd look.

The weapon was a bit of a non starter but it was mechanically way more solid than before. Somewhere between the versions I think I have my sweet spot. Those servos will be junked as a stock item. I have some ideas as to how to retool the control boards but they are fairly limited to mild 550s. This is not a death sentence just relatively easy to outgrow.

Onwards and upwards I suppose.