Thought I’d continue clogging up the forum with some build diaries!

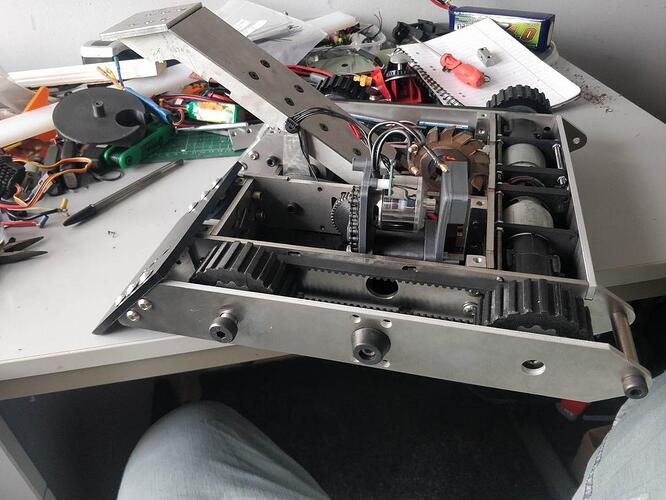

Feast your eyes on this shiny stainless specimen

Flatpack was built back in the mists of time, the far distant year of 2015. It was one of the first good robots I had made and being about 18 I was yet to find my groove with regard to design ethos. I did what any other starry eyed chronically online ro-bro would do - copy Charles Guan. Without hesitation I ran away from chunky milled aluminium to slick laser cut jigsaw puzzles. Being able to design something effectively in 2d and have it interlock together with minimal effort was great for me. By this point I was working stupid hours in a stupid job selling toasters to morons in a hardware store so time was precious.

Splatted together a fairly respectable robot though and the ole build diary for it can be found here

It ultimately had some problems. Early days of brushless, being clouted during a cease and being made out of stainless in a full combat environment being the chief ones.

A few months later seven years had passed and I had moved down the road from a very popular venue for the fun centric sportsman class of BEV’s. I had tried my hand at a couple of interim builds but getting Flatpack out of retirement and giving it a fair whack at some rough and tumble was too hard to turn down.

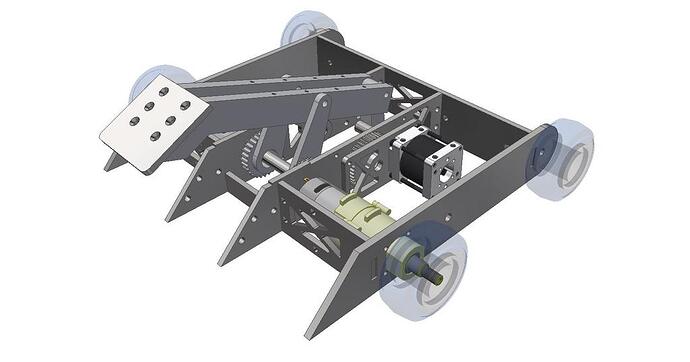

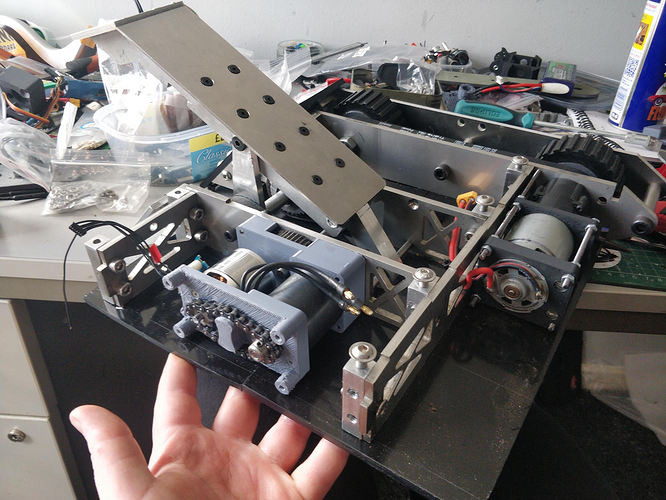

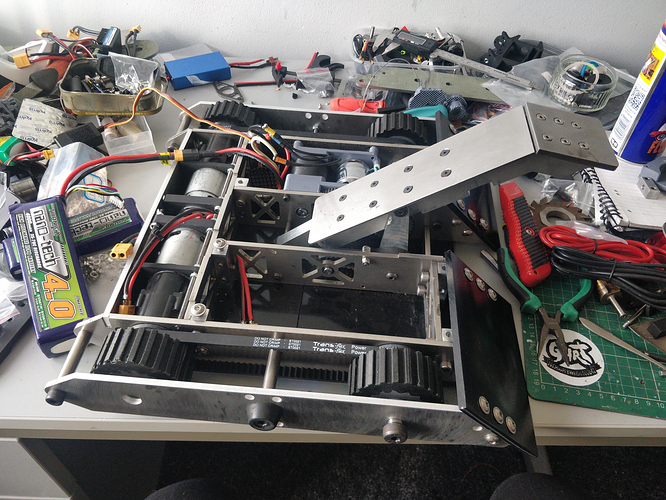

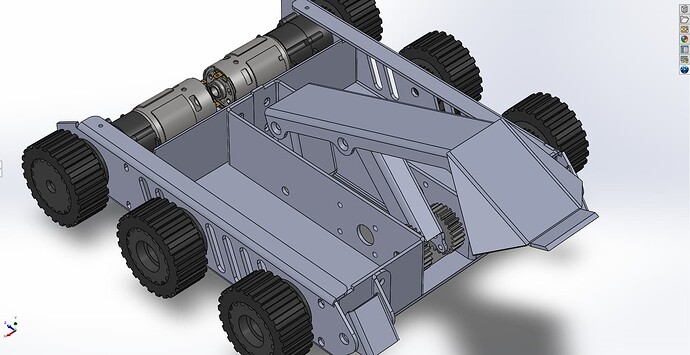

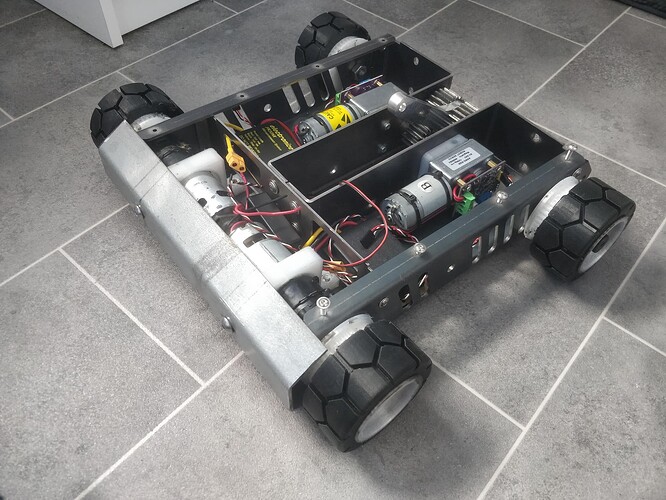

I opened up what I could salvage from the old CAD model and cursed my horrific bad habits. A lot of sketches were cleaned up and models redrawn and I could try pushing parts around. I was fairly set on keeping the core of the lifter (pretty much the only useful remaining part) and just making a minimal frame to pootle around the arena with. The rough draft just used classic old argos drills LIKE WHAT MOTHER USED TO MAKE.

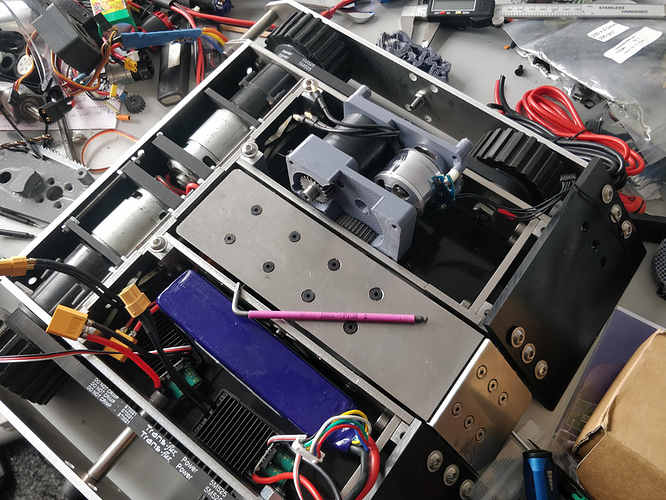

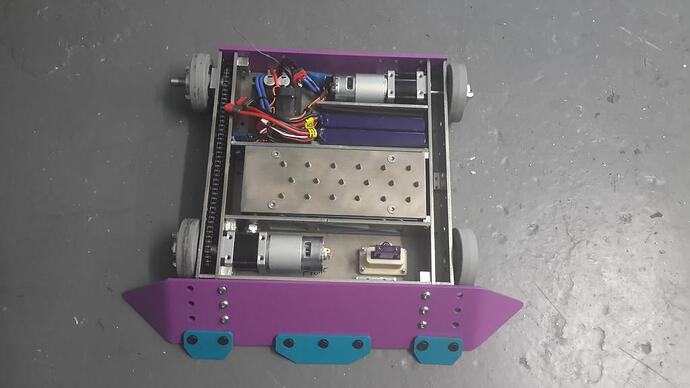

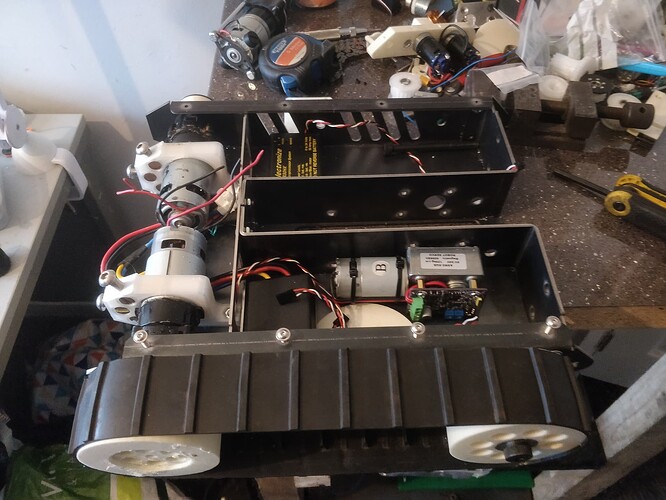

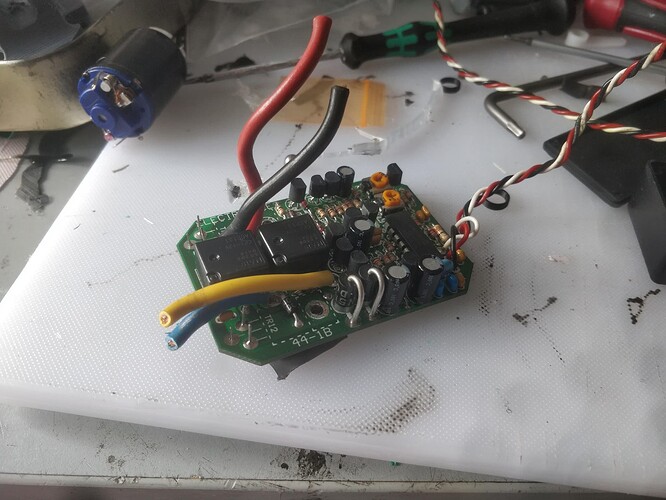

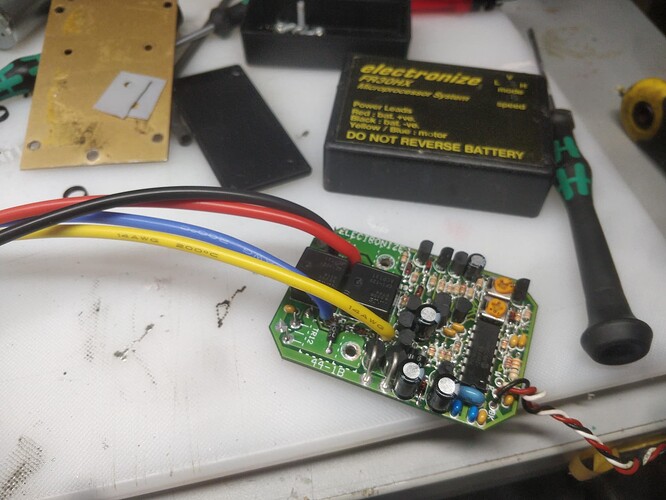

I went a little harder and switched up the drive so some more powerful 775 dewalt drills, had a cleaner sweep of components and a more reliable setup for the lifter motor. The plan was to get some HDPE cut (laser’d actually) but that fell through so I just simplified it to what was cheap on ebay and I could cut by hand.

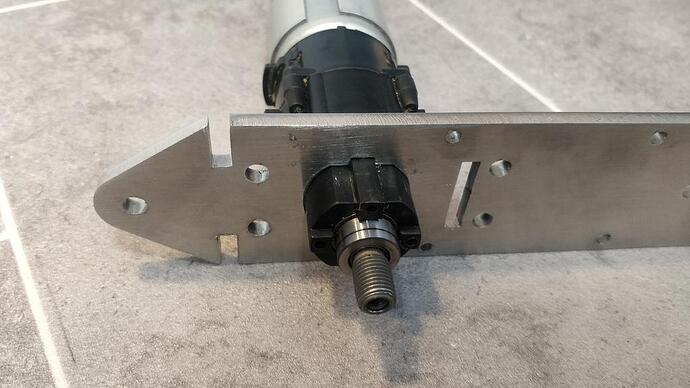

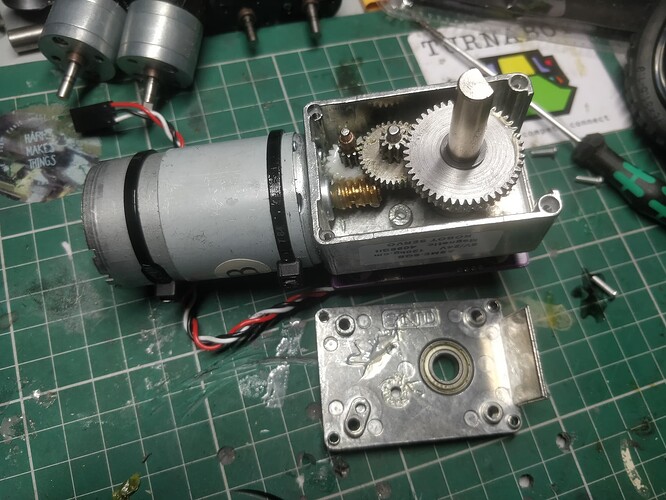

In true bargain bin BBB spirit I found a dewalt by some bins and after stripping it found it to be really pretty nice inside - like a normal drill but lärge. The speed range worked out pretty well to - topping it out to 1100rpm in high gear and 330rpm in low. This put it in the 10mph range which is pretty sedate but still may prove too much for me in a small arena.

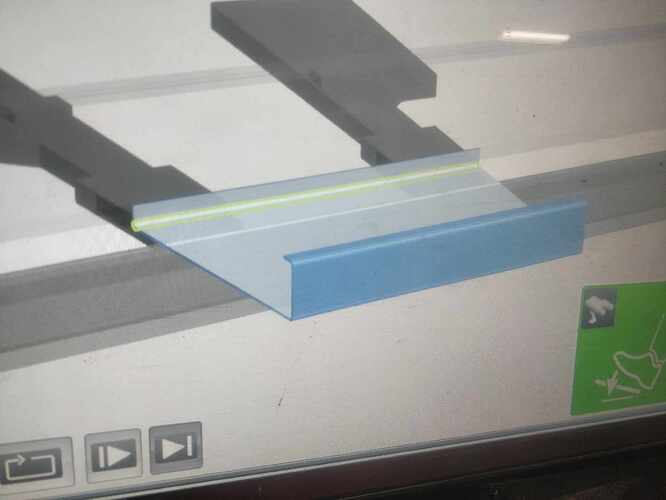

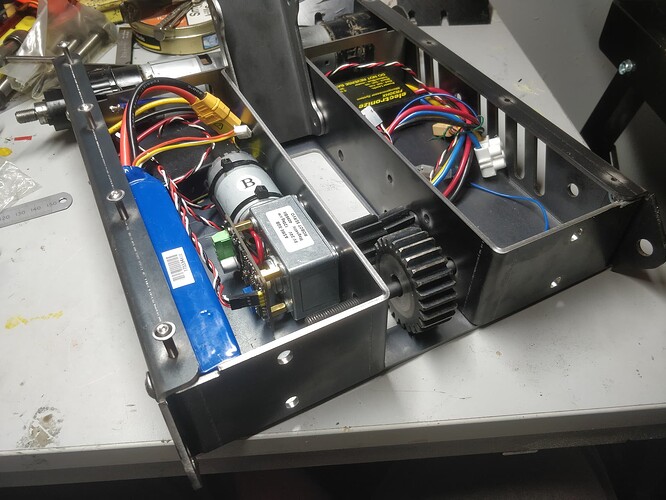

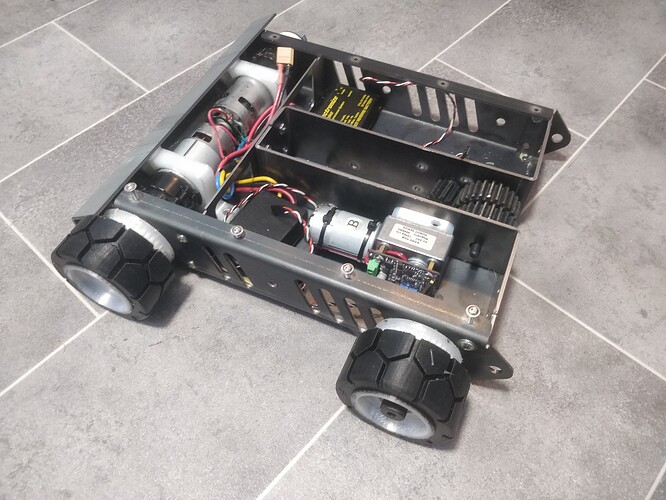

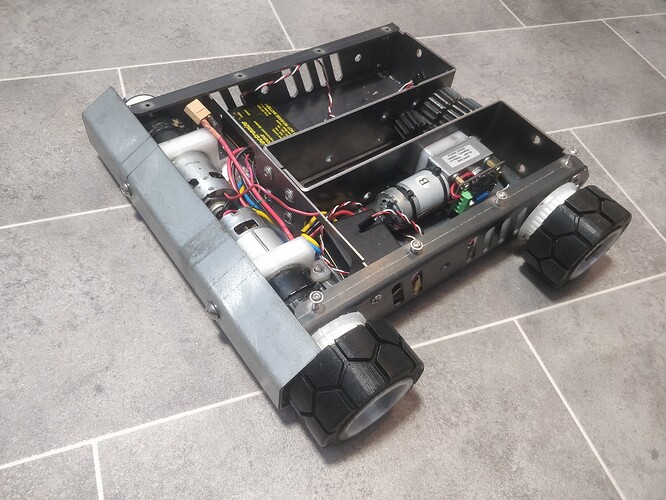

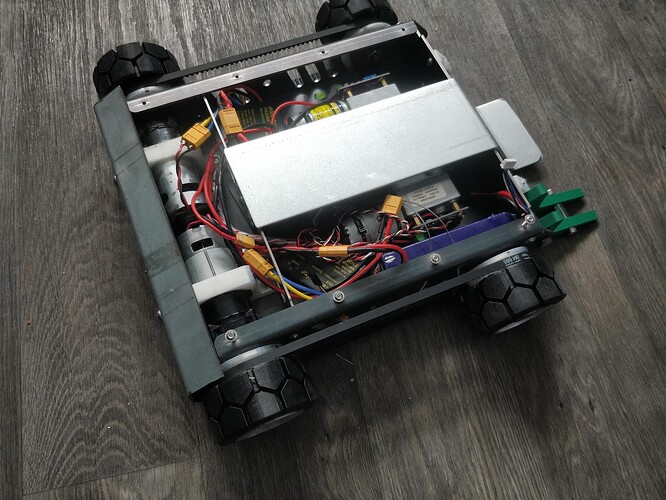

I had my bulkheads lasercut (again out of 5mm stainless for old times sake) and you can see how the drive motor interlocks. I love technology. Making a 00’s power tool fit a 2023 fighting robot is a breeze with lasers and a SW licence.

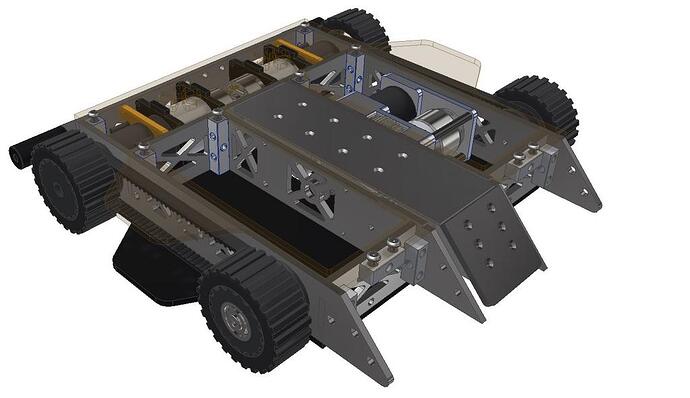

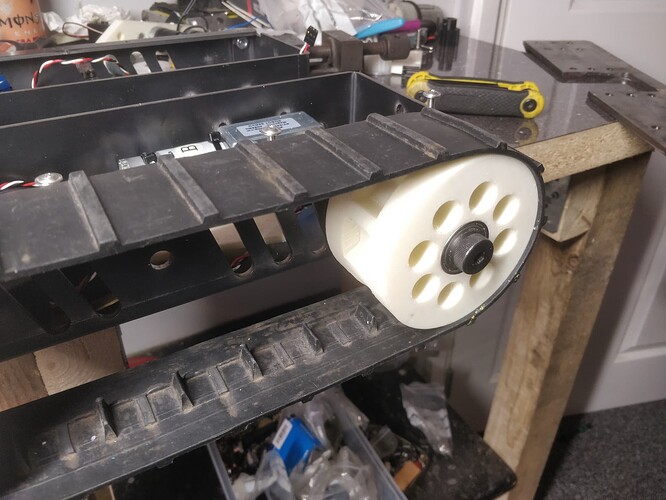

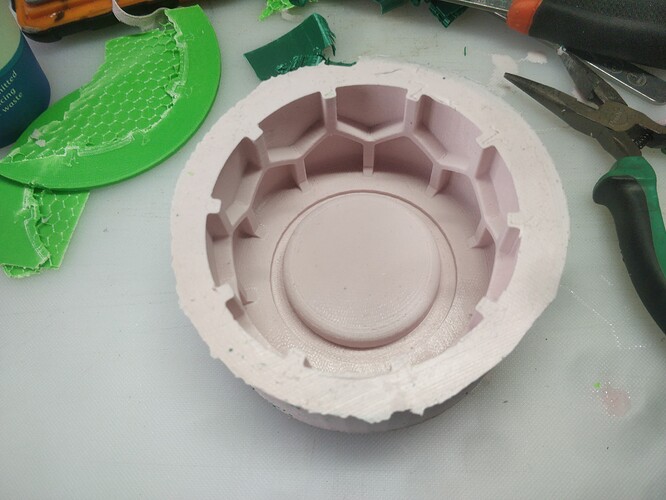

The wheels are 3d printed hubs with polyurethane tyres. The white on the right was my first slightly globby attempt and the grey is my “production” version. The front wheels have two 12*28mm ball bearings and the rears have a 17mm hex for a mini/morris wheel nut.

They each have a HTD5mm timing pulley drawn in to get that funky fresh 4wd.

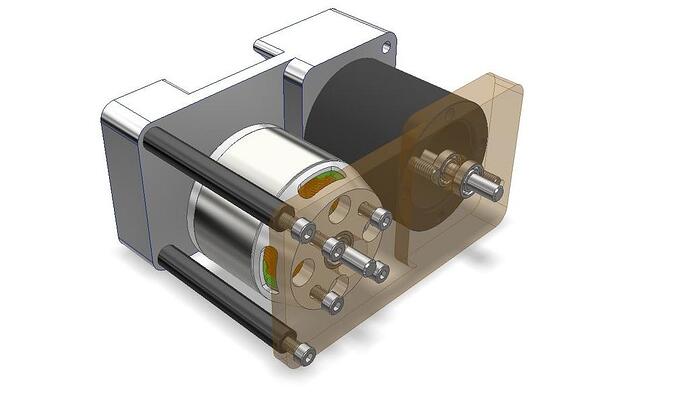

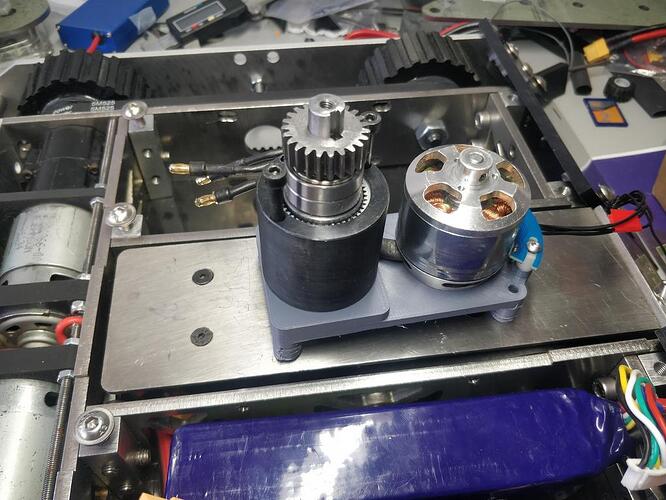

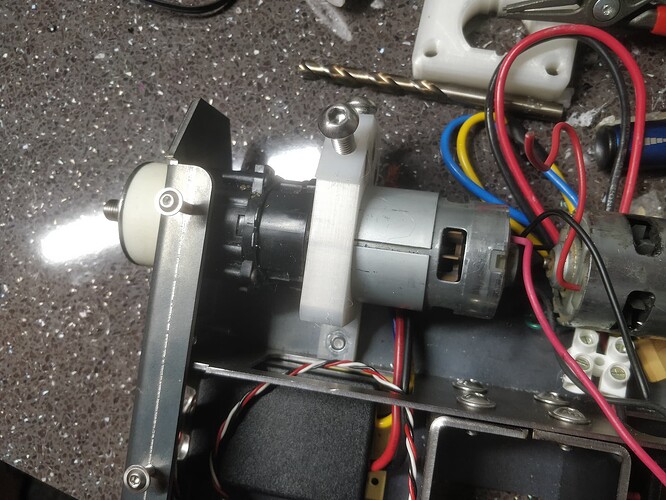

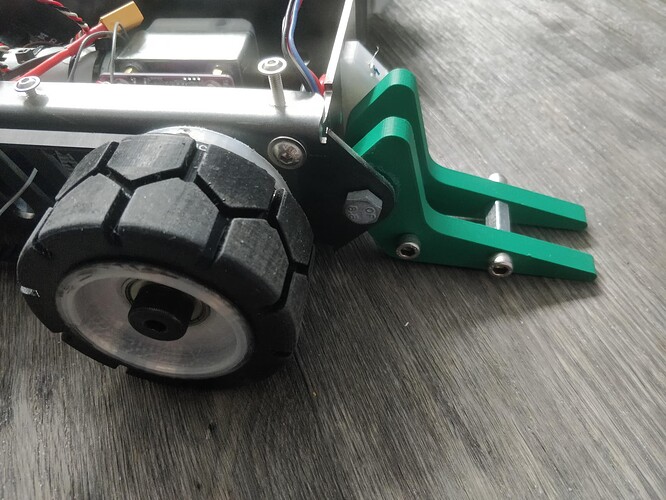

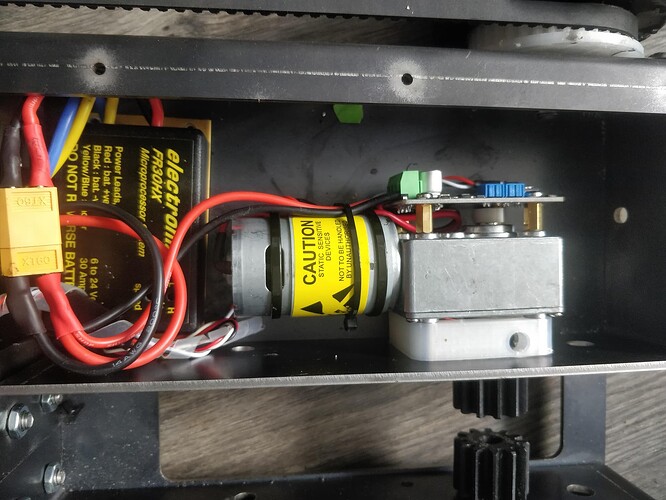

In order to fix the corner I digitally painted myself into I once again returned to the parallel mounting of the lifter motor. The gearbox is one of the mystic and illusive Saturn 64’s driven off a single chain stage by the original SK3 motor.

The motor has a custom sensor board which the lovely Si Harrison helped develop and manufacture. The gearbox housings are also 3d printed in a ballsy move - I had wanted machined aluminium but couldn’t quite bring myself to spring the dolla it would require. About 50 pence of filament seemed a better deal.

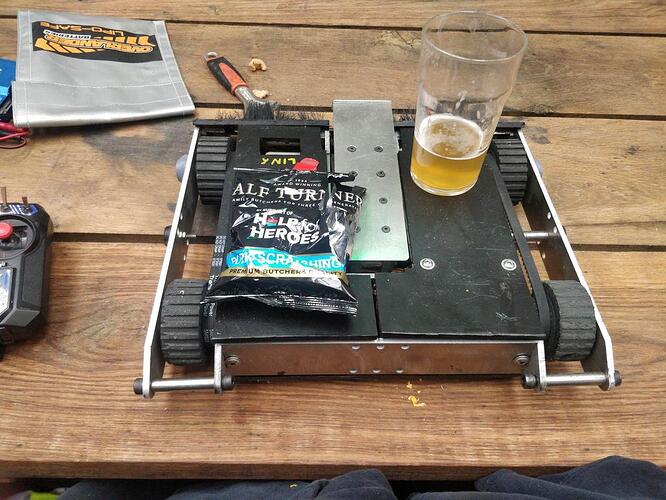

Back when I worked in the nightmare carbon factory I had a lot of time to kill and so this little lad often came with me to work for the week and I could get odds and sods done before returning home for the weekends. I was able to test the theory of the lifter mechanism pretty well here.

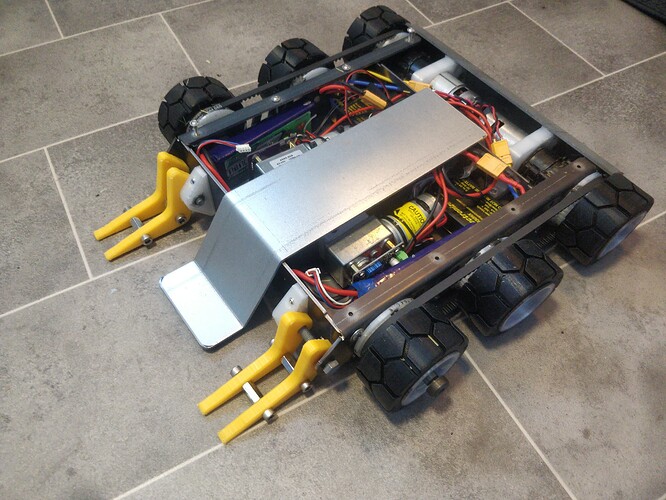

I was intending to get this running for last year’s farm bash but it clashed with the opportunity to see a running Tiger 1 tank so it sat in this state until December time when I could pick it up again and look at finishing it off for the event at the end of the month!

“armour” is fitted in the shape of some 5mm aluminium and 6mm UHMWPE and I have had it running under its own power which was pretty neat. The gearbox is getting a slight rejig and I need to draw up some internal braces and mounts for boring parts like ESC’s and links but it’s way more robot shaped than it has ever been. Watch this space!