Just had a great time at the BBB LHG Sportsman type event this weekend.

The build started to cover a small hole in Cluster plans between myself and the wonderful Jed with his super cool and very capable Cluster Half.

I had big boots/tyres to fill as out beloved lord and saviour Car was sadly not to be attending this event… pooring some motor oild out for our missing son. Feel like crap, Just want Car back ![]()

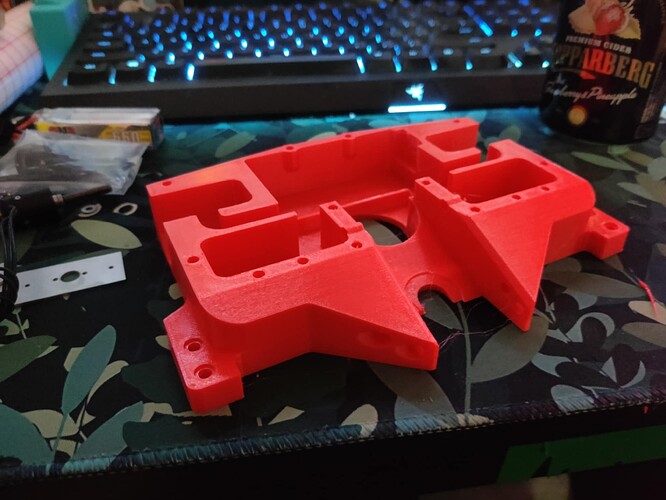

First bits made were a bracket for the weapon system and then the chassis. Mount id a slab of 608 alu and the chassis is 64D (AMS TPU) a lovely balance of strength but also flex.

More prints went underway for the chassis. had fun as ever using the AMS capabilitys the TPU has. and for time perposes some ol reliable Paint pen.

The lid had some nice large eyes, all the better for looking in to your dirty soul and at the audience for some pity points when the bot inevitably crumbled under some kind of failure.

More good ol machined bits were made. some 1.2mm stainless motor mounts to support the 16mm repeat Mk3 drive (a lovely little package with many beans) along with a hub to take a standard cap just like a traditional angle grinder setup for the 115 and 125mm flap discs intended for use.

Eagle eyed people will have spotted the custom angle grinder spanner made that is very extra as i was told but a wonderful thing to waste time on making, is i ever do.

The original mounting was a fully machined pully for a 6mm T5 belt but was lacking the ability to squeeze the desired reduction for the flap disc, so eventually changed to a 2 part hab with a machined bore with small keying features and threaded holes with the 22.2mm bore machined in to and a TPU gear fitted with a relife chamfer on the back side to sink it lower to the chassis.

The motor gear was mounted to a small alu hub. this allowed the gear to be bolted on from the top for easy access such as with the threaded cap for the flap disc too. once again also printed in TPU.

Weapon system was all assembled and is a nice little package thats much nicer now with all the bearings installed and a single part hub retained with a circlip (also if you look close you can see a threaded hole on the bottom just in case of a catastrophic failure haha).

Motor was a pretty small but ok power wise 2628. The robot runs on 3s LIHV (as i had some that were a god size) and the power is probably a decent sweet spot for the components in this application.

Robot has 2 set ups but only ran one and they were the wedge and the lil fingees.

Was a lovely first run and GG to all thear and thanks agin to all helpers and the BBB Bois. and jed for carrying on any progress we were making