Part 1 - Taking out the trash

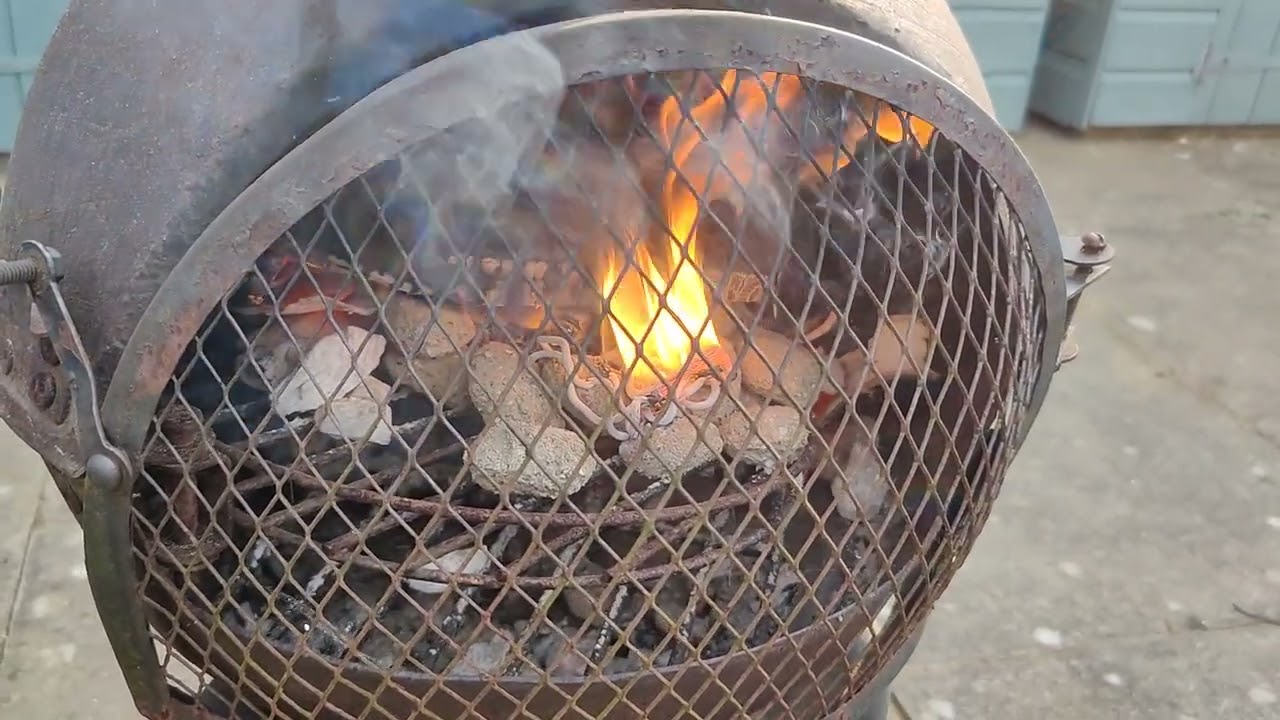

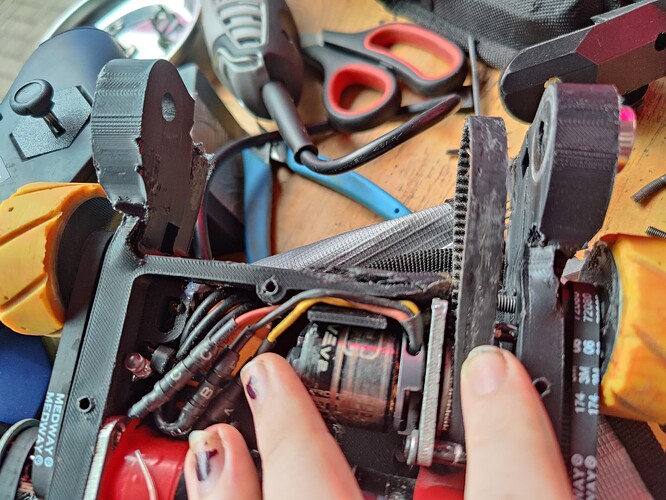

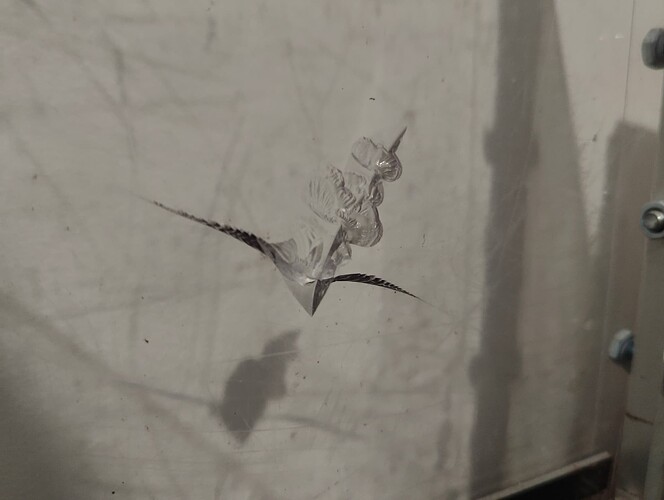

I’m not a superstitious person, but I truly believe that Ultra-Violence was a cursed robot. It never completed a single event without some sort of random failure, usually a new one that had never happened before. I spent 2 whole years trying to persevere with the design but early last year I finally had enough and decided to dispose of the thing finally. To be sure the curse was dealt with I burned it:

…and set about designing something new to replace it. In the meantime, Matt Smith convinced me to get back into antweights, and to be honest this probably single handedly saved me from taking an extended break from robots entirely. I had so much fun running an ant again it rekindled the love I had for this sport that Ultra-Violence had been slowly killing, but also helped me find the inspiration I was missing.

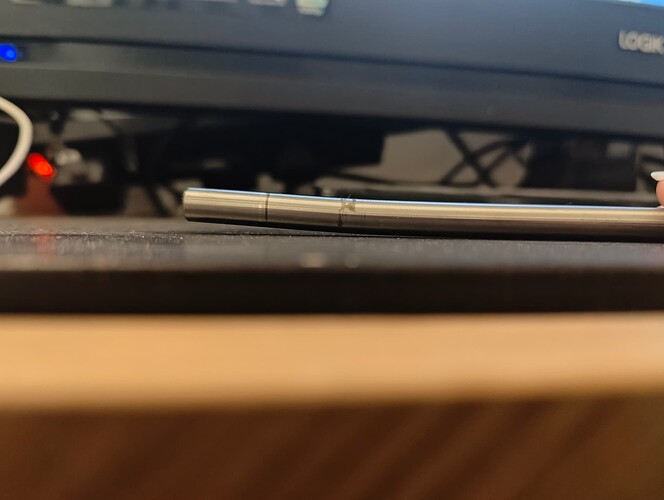

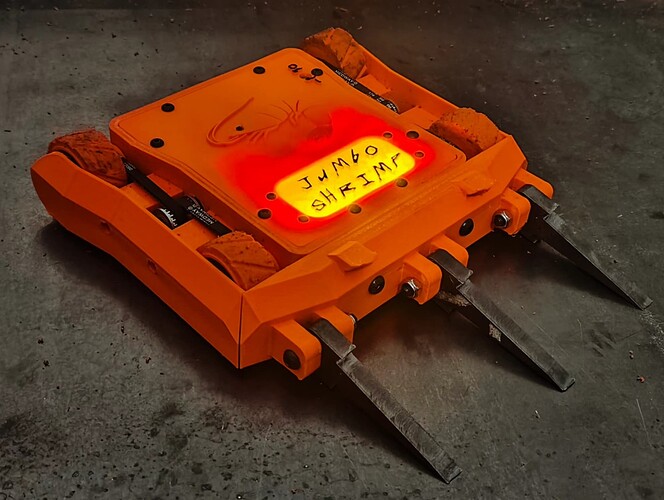

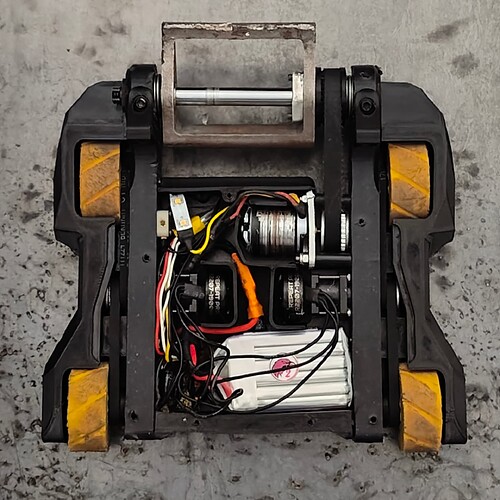

Antweights physics are weird; they’re tiny and have so little mass behind them that things like centre of mass and momentum etc don’t matter and they drive very precisely as a result, with no drifting or acceleration time. I wanted to see if I could translate this sort of feel up to the beetle class, using very powerful motors and a heap of magnets. Now I’d avoided brushless drive in all my bots for a very long time, I always had concerns about reliability and fine control, but with the introduction of AM32, and with how anemic the brushed drive on UV had been, it was finally time to make the jump.

I looked at all the options and decided on the Repeat Max, mainly because I wanted to run this bot on 6S for the extra power and the Max are rated to run that high, while the other options like MegaSparks only state 4S as their maximum voltage. Originally I planned to run a pair of Repeat AM32 ESCs, but while looking through the Palm Beach store for a group buy of ant batteries, I spotted the Repeat Dual ESC. The integrated BEC and onboard current limiting sold me, and I got one imported along with the batteries.

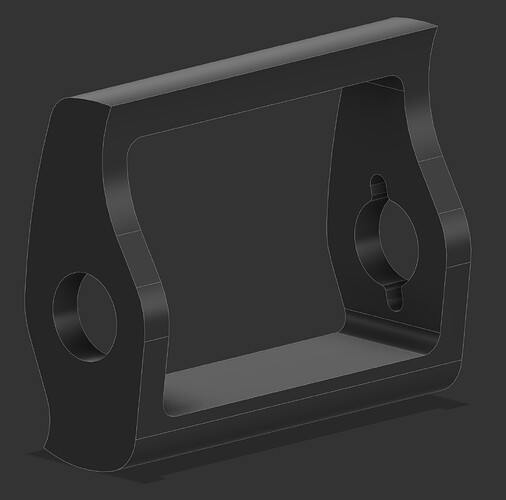

I liked Ultra-Violence’s weapon, when it worked, which wasn’t often, but was the part of that thing that had the least issues, so I kept the setup largely the same, although I changed the motor mounting since the aluminium angle bracket I had been using had issues with bending, now using aluminium standoffs into the side of the frame which was much more solid.

The weapon motor is a Propdrive 2836, which is only rated up to 4S, but I know has been run at 6S in some US beetles. I still wanted to be sure the motor didn’t die from too much current so I put out some feelers for an AM32 ESC with enough guts for a motor that size and current limiting. Ellis was testing out some ESCs that fit the bill, and I agreed to test a couple out.

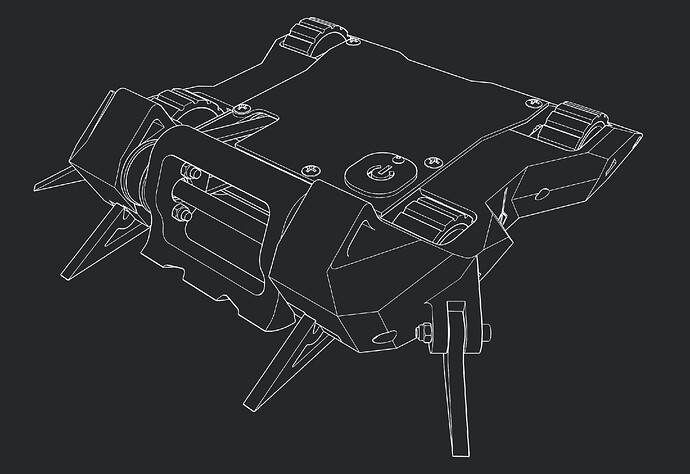

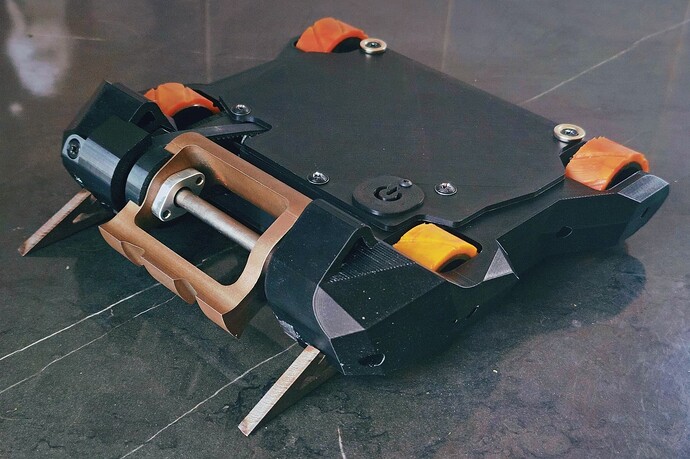

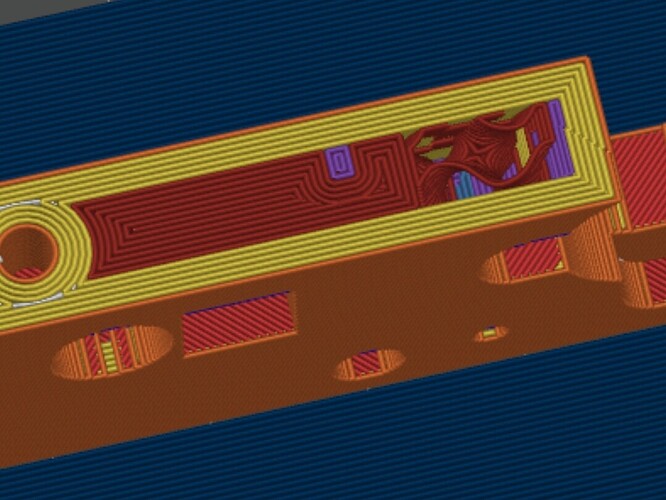

Originally the design was heavily inspired by Manta from the US, with a much wider more drum like weapon, but it ended up so heavy I ended up redesigning it into more of an eggbeater. At 80mm across it’s still pretty wide for a beater, but the proportions of the bot ended up much more square, although a lot of the style of the Manta inspired design stayed the course:

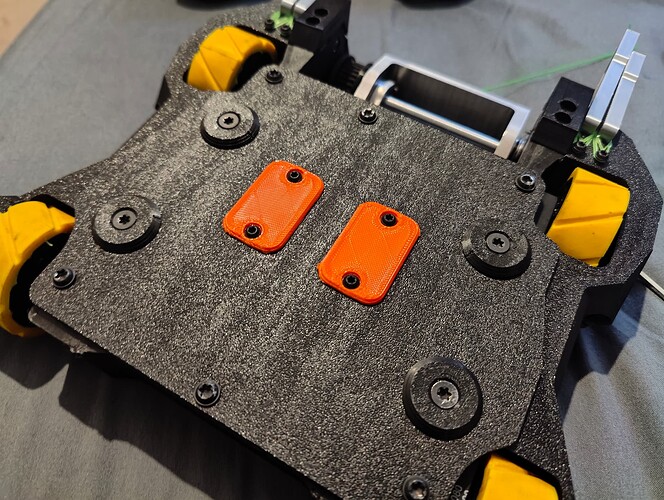

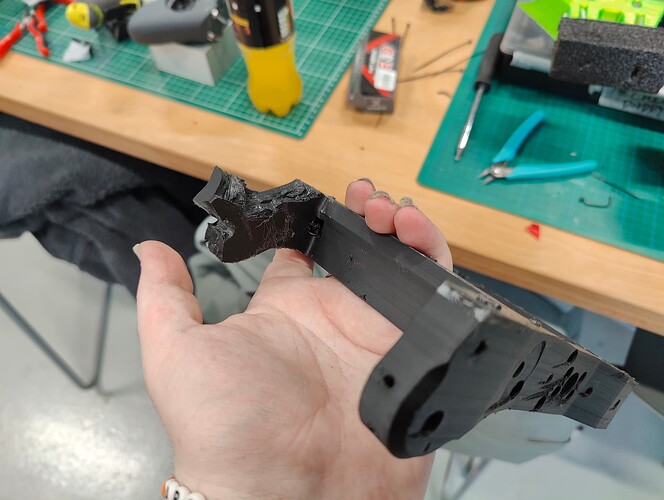

The entire robot is 3D printed, much like Ultra-Violence before it, but rather than using TPU for everything I was looking at different materials for the chassis since the TPU was far too flexible and caused a ton of issues. I’d tried nylon on UV at its last couple of events, printing the chassis from a reel of Taulman 910, but even in the handful of fights it had the nylon chassis had already cracked. So I needed something more rigid than TPU, but more flexible than nylon. Gus turned me onto OBC, which has a shore hardness of 55D, still somewhat flexible but a lot more rigid than TPU, as well as having the added bonus of being a solid 35% lighter.

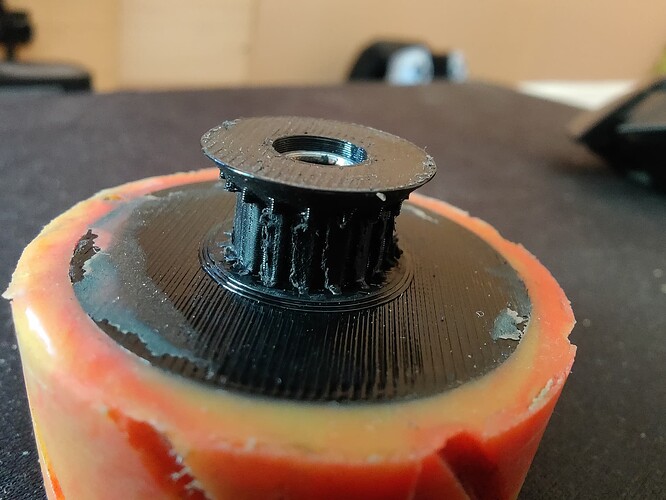

The catch here is that OBC is a polypropylene variant, which is infamous for being a total pain to print well due to its tendency to warp. Supposedly OBC is less prone to warping as it prints at a lower nozzle temp, and that is true, but it’s still a lot more warpy than even nylon and printing a part as large as Frenzy’s chassis still leads to warp around the corners:

I tried a ton of different things to help alleviate this issue but no dice, whatever, it’s not bad enough to render the chassis totally unusable so I just ended up accepting it was part of using this material. The chassis was printed with 6 walls and 15% infill and came out super light, about 90g all in.

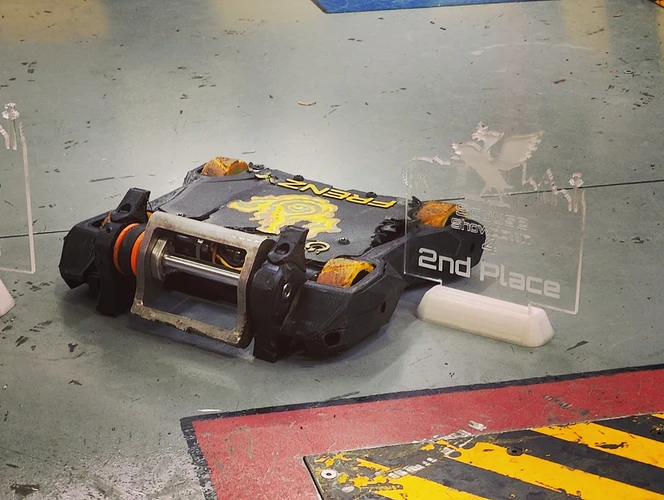

All parts printed, wiring done (thanks to Dave) and all fixed together, Frenzy was ready for her first event: