Hi all,

Crushers are cool.

Crushers are cool, but boy are they slow.

Crushers are cool, but boy are they heavy.

Crushers are cool, but boy are they complex.

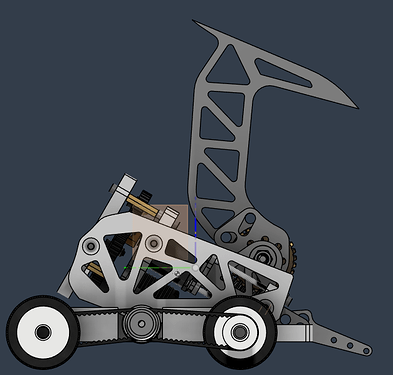

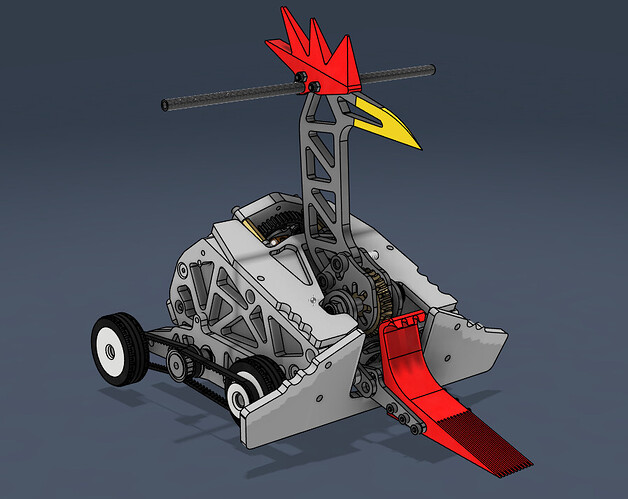

So you’ve got to dedicate a bunch of weight to something that will be extremely complex, likely slow, and might not even work. There are several ways to go about this engineering conundrum. If you’ve got a tormach you can make one of these:

If you don’t have a tormach but you’ve got some serious brains and skill, you can make one of these:

If you’ve got some serious brains and skill but you don’t like finishing your beetle, you can make one of these:

(sorry Harry)

There are loads of different techniques available - some better than others. You could do hydraulics, which are big and heavy and full of oil and all sorts of other things. Not super viable for Beetleweight though people keep promising that they’ll crack that nut. I hope I live to see it.

There’s the venerable lead or ball screw, used in Unconscious 514, Antithesis, and Mr Nips (and indeed other linac crushers). These are fun mechanisms that are pretty well worked out at this stage. They’re slow, but you don’t need a massive motor to go through stuff. They’re heavy and you need to play with geometry to get them to work as well as possible, but they’re proven and they’re as close as we’re gonna get to a big hydraulic piston at beetle scale, which is sick.

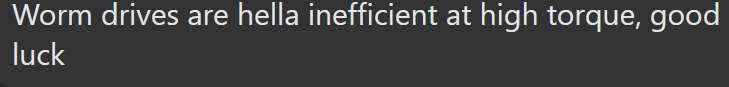

And then there are worm screws, like the one used by Inside Job. But worm screws are inefficient…

When it comes down to how to approach building a crusher, the real answer is we’re all fools, trying to do something that takes enormous amounts of power and weight to achieve what the hammersaw builders do in their sleep.

Hammersaws are cool…

But they’re not Crushers.

Part 1: Sensual Reduction

I am not a smart man.

This is evident because I do combat robotics rather than something cool like playing guitar at the pub (people love it when you play guitar in a crowded pub).

One thing I do like is gearboxes.

All those gears, working together, getting the job done as a team - it’s a lesson for life.

I’m actually kind of a big name in the gearbox world. I was the first ever person ever ever ever to put a big motor on a high reduction gearbox and put it in a robot. Ever. That’s why it’s called a Strangbox duh. No-one had thought of it before.

When you put power into a gearbox, it changes, shifts in some sort of arcane way, the speed going down and the torque going up in a relationship that some scientists have described as ‘it’s complicated’.

Here’s the bit where I tell you I’m not an engineer or a scientist and I don’t know what words mean. speed go down, torque go up, more crush crush. Perfect for something that’ll crack through your hard outer shell and get through to the real you.

One of the great things about not being an engineer is I don’t know when to stop doing dumb things. Gearboxes are great, which means they cannot possibly fail, I can just keep pumping power into them forever. And everyone else was building crushers with diddly little motors, which meant slow crushing, which meant no rizz. And I was desperate for rizz. My objective with this build was never to outdo Jed in crush force or driveability - Jed is streets ahead of me here. I just wanted it to be reasonably simple to build and repair, fun to drive, cool to look at, and most of all, with a fast crushing head - no waiting the full 20s for one crush and release, I want it fast and I want it now.

Worm gears could be the answer, they’d be faster than a lead screw crusher, a bit simpler because I only need the claw to pivot on the gear, no converting linear action into rotation around a point, nice and easy. But they’re inefficient.

I’d been swapping Repeat Ultra hex shafts into 28mm aliexpress gearboxes in an attempt to get around the ‘Strang built us all gearboxes for Rapture 2024 and all of them broke and now we hate his guts’ energy that was going around. Weird vibes right?

Rapture 2024 was a time. And I wasn’t even there!

The repeat ultra axles have a lovely 7mm face to face hex (ummm actually it’s an 8mm REX™ profile you philistine). People make all sorts of fun stuff for this specific bore pattern, and one day I stumbled across this naughty little wheel of cheese:

So sleek! So sexy! Quite expensive really! But could you think of the prestige! How the other builders would look at me when they realised I had a part made by actual engineers on my robot?! I’d be the talk of the town!

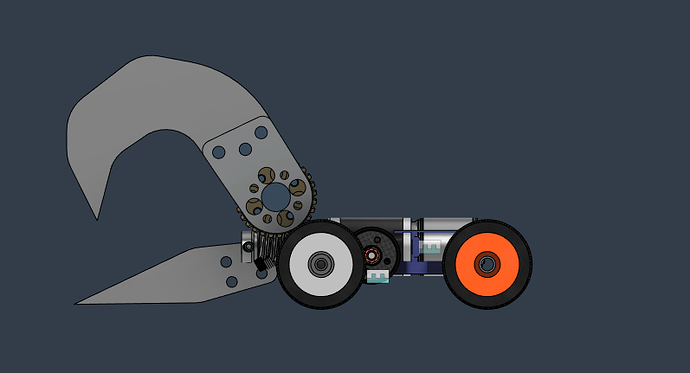

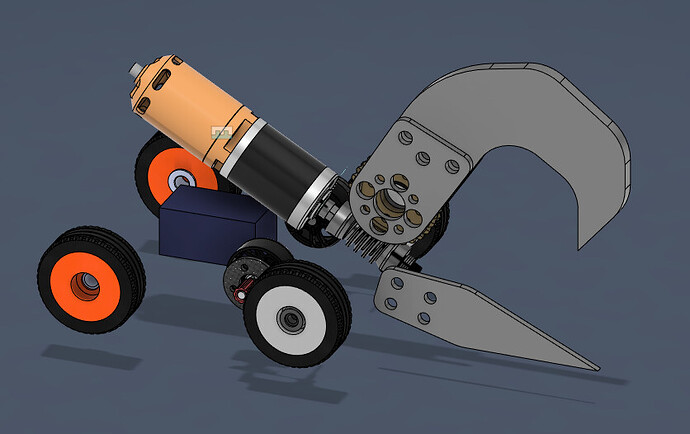

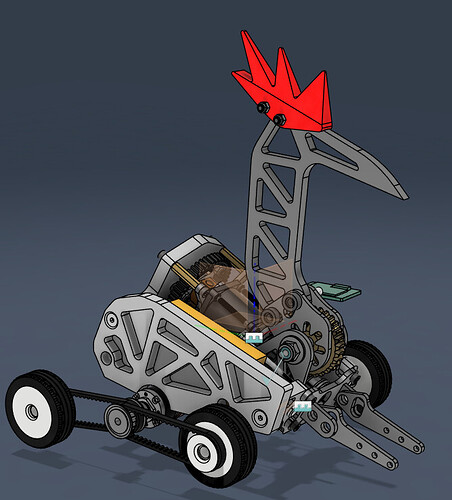

My dreams of fame guiding me in a trance like state, I quickly designed my magnum opus:

Sexy worm gear, sexy tangent drive, and lego wheels instead of the dogshit foamies I’d been on for years - this was gonna be cool. Crushers are cool, I told myself as I climbed into my racecar bed, sunglasses firmly fastened to my head. I am cool too, I whisper to myself as I drift into the great unconscious beyond.

Part 2: Will you take me to, Clunky Town?

I spend a lot of time in CAD when designing. Not because I like it but because that way I can listen to my tunes. With the gentle melody of Don Omar & Lucenzo’s 2010 masterpiece ‘Danza Kuduro’ playing softly in my ears, I sat down and got to work. The Strangbox is a big ol block of clunk, it’s making this robot so long and thus so heavy - what if I tilt it?

Tiiiiiight tight tight tight! Very cool! But that motor is a little weedy, only a 2836? Surely I can do better, and maybe if I avoid buying something new I can save a bit of cash? I’ve had those massive Tmotor 2814 (stator size) motors sitting around for about a year, those have beans to spare!

But they have a 5mm shaft and I need 4mm… no bueno. I’m not pissing about trying to get a different sized pinion for the motor, the insanely big brushless motor crusher will have to remain in my dreams.

But maybe…

maybe I could use a longer 28XX motor and get a bit of extra power that way!

That is not cool. Crushers are supposed to be cool. How will people think I’m cool if they see that?

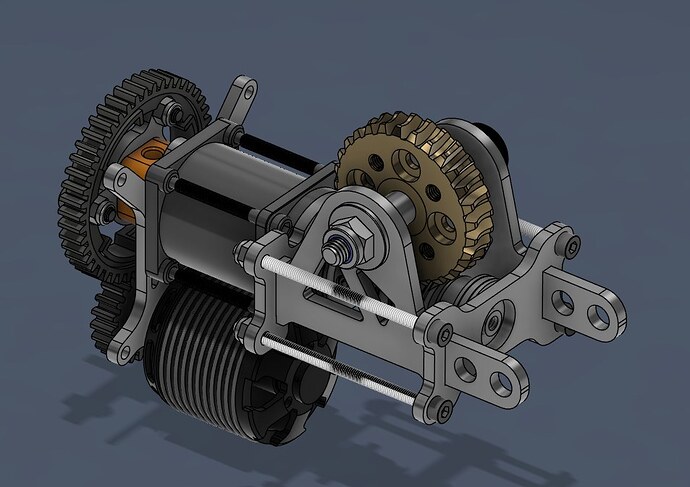

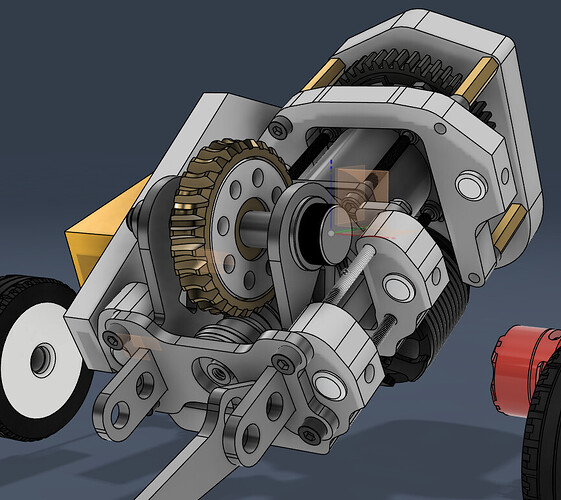

Let’s just bite the bullet, these are all too long - the Repeat 51:1 ultrabox has less reduction but is shorter, significantly so, than the Aliexpress 28mm boxes. Sounds like a plan.

But I want it even shorter. I could put the motor below or to the side of the gearbox and then just run a spur section to the box. The spur could even add a 2:1 stage of reduction, more crushing power for a touch less speed. Sounds cool. Plus I can use those big fun Tmotors.

That is a lot of metal. I’m not sure but I understand metal to be heavy. This looks heavy.

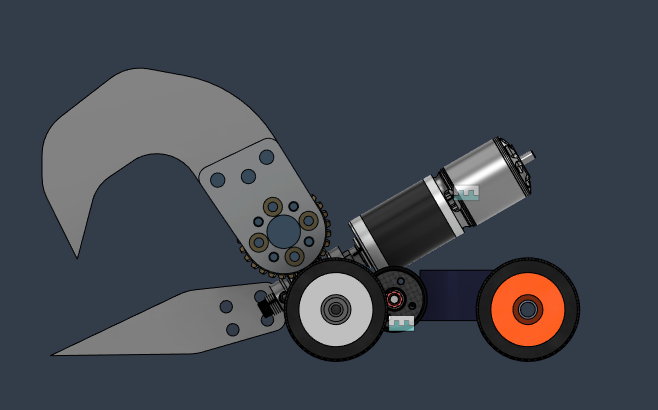

I guess it’s gonna be pretty strong, I could always wrap a robot around it and use it as the main structural element. Like an F1 car, if it was designed by Massey Ferguson.

This looks like a good approach - lots of plastic to connect everything together, electronics outboard of the crusher - might have to shift those inboard to save some weight on extra panels.

It needs a claw too, something that doesn’t look like anything else out there, something a bit animalistic…

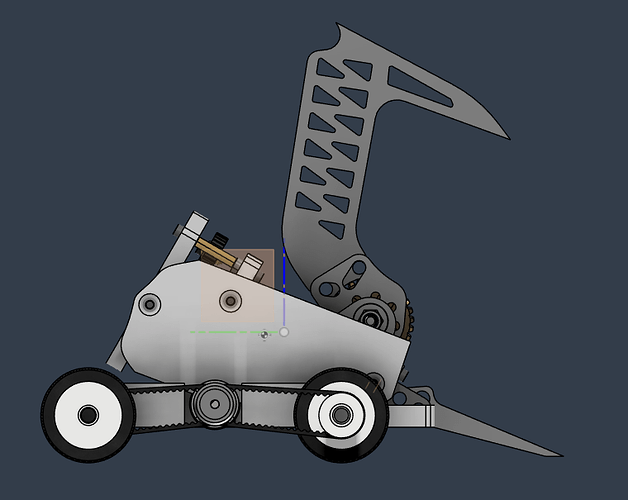

This is so clunky, so ungainly. It’s like some sort of horribly diseased giraffe. It’s not cool.

Crushers are supposed to be cool.

Part 3: How do you make a robot look cool?

I wish I knew the answer to the above question. I was not happy with the design, it felt like it had a bad personality and drank too much white lightning out the back of the skatepark when it was a kid. At least I could relate to it but I’m not here to build another friend, I’ve already got my Kermit the Frog sock puppet.

So anyway I stumbled through some weight saving because Fusion was telling me that this thing was heavier than the sun. It gave some vibes where they were sorely needed - pockets on the outside are cool.

I also improved the claw a bit, adding some visual weight to the rear of the head. Still, something’s missing.

Enter Sarah, my partner and visual wizard. She’s got the sort of brain that actually knows how to do things good, like really really good. She took a half glance at the bot and said ‘it looks like a chicken’.

After a quick google search I was on board. The name followed rapidly. ‘You should call it Heckin’ Peckin’'. I don’t know where I’d be without this woman. Thanks Sarah, you were a star throughout this build, always pushing me to have fun with it and just let loose.

Some chickens have a red bit on their head, as so:

This would be a breeze to add, and, if I played my cards right, could bring the whole build together.

All that was left to do was finish the chassis, the drivetrain mounting, the front end and attachments, the shaft constraint for the 2:1 stage at the rear of the robot, any sort of self righting I could fit in, and get it in weight, get parts ordered, get parts cut, get stuff printed, get it assembled, solder the circuitry, test the weapon, test the drive, and then enter a competition.

I did, however, manage the digital bits fairly quickly:

I entered the Pub Beetles event before I’d gotten to this stage as a way of forcing myself to actually build a robot. This time I wouldn’t let anyone down, I had loads of time, it would be ready well before the event. Being on time is cool.

Part 4: I am bad at time management

Yeah so anyway I didn’t build anything until like 4 days prior to the event. Massive thanks to Rob Webb, Joe Mitchell, Jed, Joe Brown, and Tweedy for providing me respectively with Plastic, Steel, Prints, Prints, and Steel, without the lot of you I would never have been able to build anything. Thanks also to Jack Franklin for supplying some spares and lighter parts when I lost stuff. You’re all absolute babes.

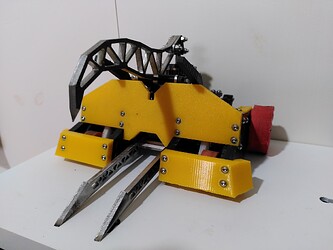

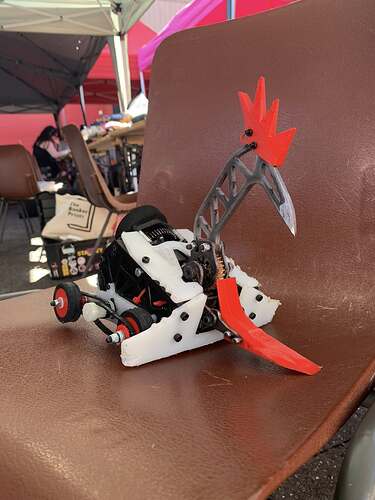

The robot did, however, get built:

A finished robot, at the event. I arrived at 11. It took me til 1:30PM to get it finished. I am so sorry to Joe, Craig, Gareth, and the rest of the crew. I can be better, cooler than this.

So, a built robot. That was too heavy. I slinked in at 1500 dead on the scales after swapping a lot of parts out and getting rid of a lot of heavy things. Crushers are heavy.

Part 5: 0-3 and I love it

Yeah bit of a spoiler, the crusher worked for one crush in the first fight and then got stuck down - I forgot to space out the repeat box input gear so it had some play and could slide out of mesh. Womp Womp. Still, easy fix, and I’ll add the wheel to the back that allows it to kinda break dance self-right:

Bigger issue: I had ordered some alu pulleys from China, which never arrived. With days before the event Jed offered to print me some nylon ones with a D profile in the shaft bore. Great, I thought, this will work, just a bit of glue to hold them seated. Unfortunately the heat in Bristol at the weekend decided it had Such Sights to Show Me and melted the face D bore within about a minute of the start of each fight. Definitely not me trying to put beetleweight drive through something that only really works at ants. Fine, whatever, I’m here to be cool and have fun not to win - as long as I can drive well for a minute and do some fun crushing, life is vibes.

So I fought Tsukikage and crushed the top in a couple of times and fell on my back and breakdanced upright and then the drive died and the weapon decided not to work at all anymore. I had melted the pads off the 50A ESC I’d picked up off Joe Brown, and had no spares. I’ll just solder it back on in 32 degree heat sounds great.

It didn’t wooooooooork. But I don’t mind, I had a laugh for the rest of the day and just sent it in my fights til the drive died - sometimes faster than others. Earnt myself a lil beer coaster, thanks boys, and had a lovely ol’ time.

So what did I learn? Very little. Worm gears probably are inefficient enough to cause the amps to hit a pretty high level - new ESC to come I think. New pulleys are essential. I can actually make the body a bit smaller, as all the electronics fit in one side of the chassis. Need to save weight in the mechanism as it’s the only place where that kinda thing can be found.

Most of all though, I learnt:

Crushers… they’re pretty cool.

Postscript: Thanks to everyone who helped this build come together - you know who you are and there are too many of you to name. I love you all, in spite of the court order.