Id been messing with the idea of a feather dolos pretty much after the beetles showed promise, however with my previous experience of fc feathers i was pretty apprehensive about it, and with the Fc feather scene in the uk being on hiatus it pretty much sunk any serios ideas outside some cad day dreams, However with drg announcing an event in September (at the start of the year) and having never been on a holiday outside the uk i figured it would be about a good a time as ever to build it

I knew going in i wanted 3 main things

- powerful drive, preferably brushless

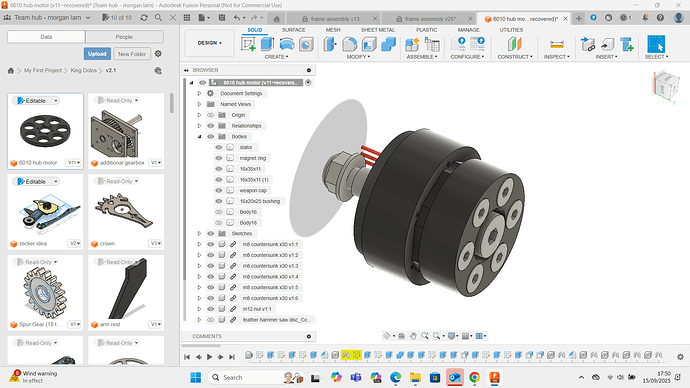

- hub motor weapon

- clutch for the weapon arm

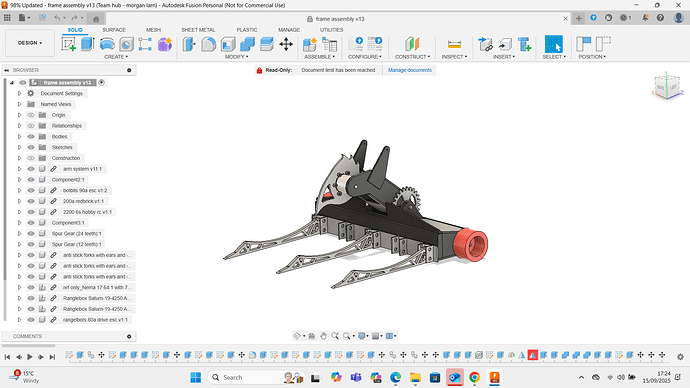

Now i had a design already

this thing

did occupy most of the 3 things i wanted to varying degrees of success however was lacking in a few main areas, mainly the weapon system. the hub motor was based on a 5060 380kv, which meant the bearings where very far away from the arm, meaning it would likely get pretty twisty, and the clutch system on the arm left allot to be desired also being pretty badly through out. the drive however would of been fine being based on ranglebots motor/gearbox but those were out of stock when i went to redeisgn it so ditched them in favour of a custom solution

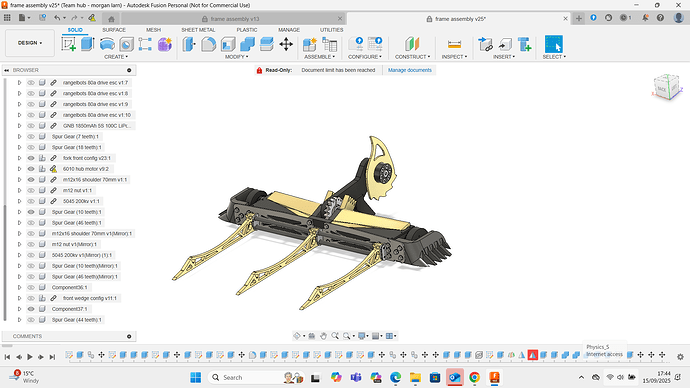

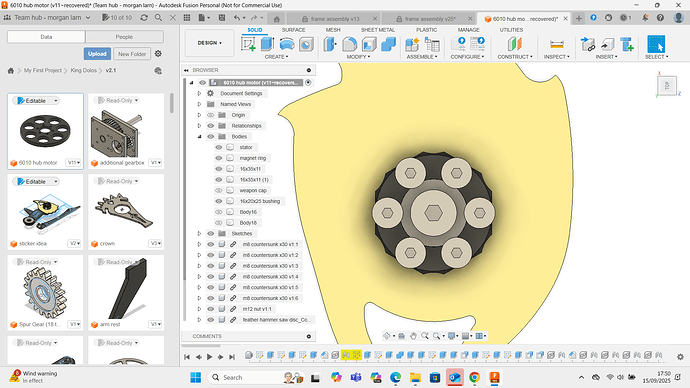

this lead to a total redesign and this

main changes are the hub motor, its now a eagle power EA60 350kv, much flatter and higher power output than the 5060 and the lower kv means i can run a 288mm diameter weapon bang on 250mph.

decided to go for a different mounting method to the beetle, rather than having the bolts go through the blade it clamps in place. should make it easier to mount

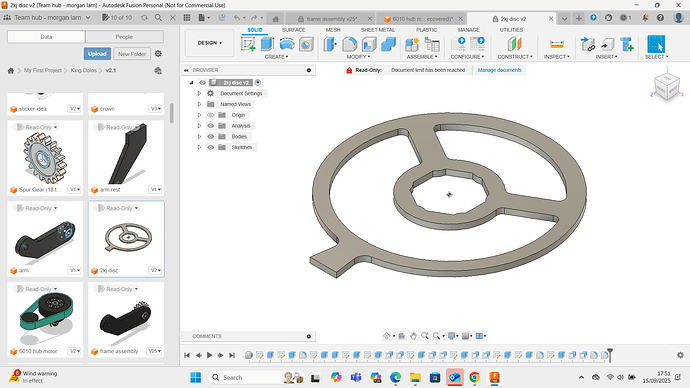

blade design is pretty much just a scaled up beetle weapon and weighs 800 grams, i also have a disc min maxed for ke (the drg limit is 2kj)

wont be expecting this one to penetrate much armour more design to deliver more shock into hardox lids or lifter arms ect, it spins on a 16mm shoulder bolt

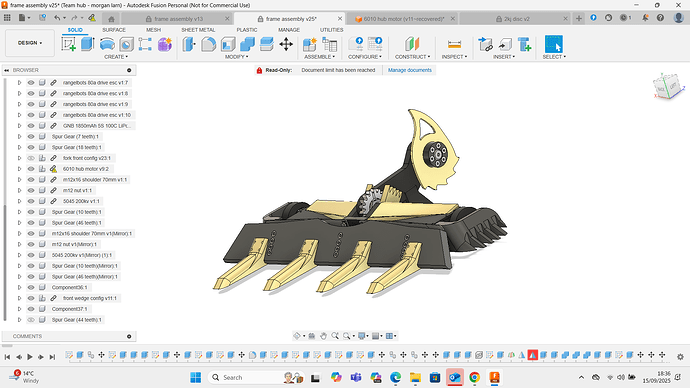

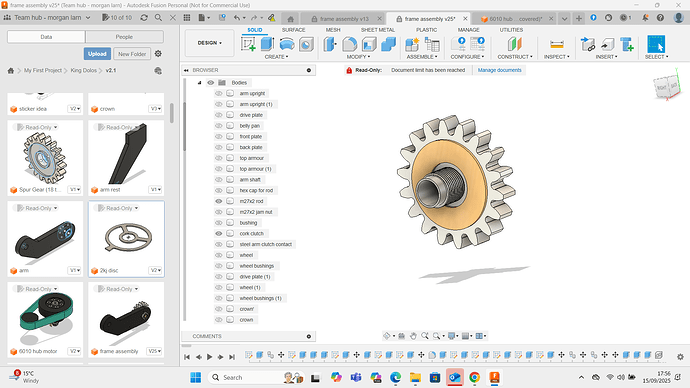

the most intresting change i think is the arm clutch system, based around the age old cork clutch it uses a m27x1.5 threaded rod with some bushings in it

the steel is there to provide a surface for the cork to grip on the hdpe arm, the two surfaces are clamped together by a pair of nuts on the threaded rod until the bot can self right but still make the clutch slip when it reaches an end stop

the arm itself is powered by a 100:1 42mm gearbox from aliexpress not the most robust set-up but with the clutch it seems to work. i made a en246 shaft for the gearbox to replace the cheese one on it from factory

the motor is a 2814 sunnysky 580kv, my brushless esc seems to not like this motor as it has some issue on start-up, so going to swap to a slighter bigger and faster motor a race star 800kv 4250 to hopefully increase the arm speed however it had more than enough to self right the bot

i did mess around with using a 256:1 banebots gearbox but this proved far too slow

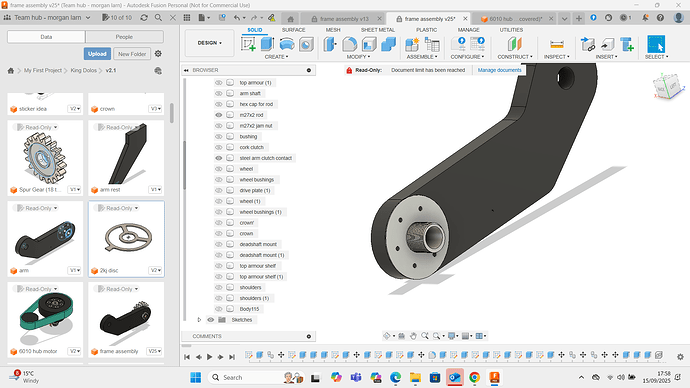

drive was originally some old 5045 140kv brushless motors on a 4:1 reduction, in hindsight this was way too little reduction but these motors seemed to not like being driven by my escs, i suspect the kv is too low for am32 so i pivoted to some 5060 380kv motors, more power but with the single reduction was still too little so had to make a secondary reduction

to do this i thankfully had some additonal gears in one of my old feathers that was the correct module and made a small gearbox to mount them, giving me 12:1. drive is a little on the slow side at 9mph but it seemed very controlled and have great pushing power the wheels as well were great being “brazil wheels” 100mmx50mm wide vulcanised rubber wheels from the same guys behind black dragon. little expensive to import but i had them from a previos bot and wanted to use them

(sorry for the poopy image quality)

the final main change was swapping from hdpe bars in the cad to bolts with hdpe spacers in the real bot, this was a silly idea to start with tbf and glad i changed it

the main frame of the bot is all 15mm hdpe with 6mm lids base and rear armour. the beetle has never had great armour so the feather reflects this

some glory shots before taking it to dojo. still got a bit of a to-do this before i take it to DRG in 2 weeks time

- loose some weight, its currently half a kilo over in its heaviest config but im pretty confident i can get that down

- make spares

- redeisgn the arm locking didnt consider how to lock it until the morning before dojo because i thought i could just drill a hole through the gear, ofc with the clutch this isnt really possible

- new motor shafts, the current ones slightly rounded out at dojo around the set-screws

- and finally some gold paint

will attach the breakdown from dojo shortly, thanks for reading!