I’ve always had a love of saw based robots, with dead metal being my favorite robot as a kid. I’ve never made (actually finished) a saw robot, but I’ve had a few attempts previously.

Struck with inspiration at FF, I hastily scrawled down an idea for sportsman featherweight, entirely based on a pun.

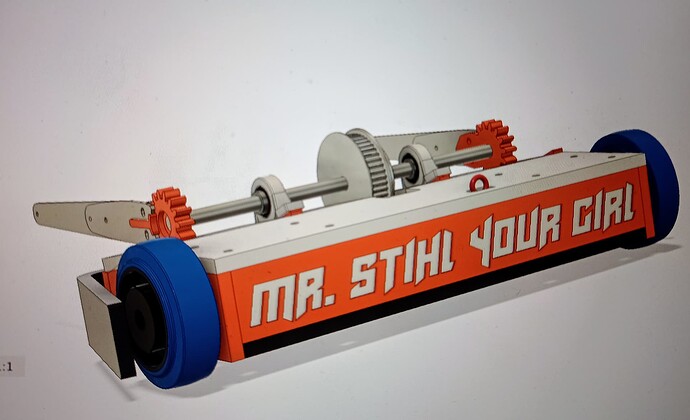

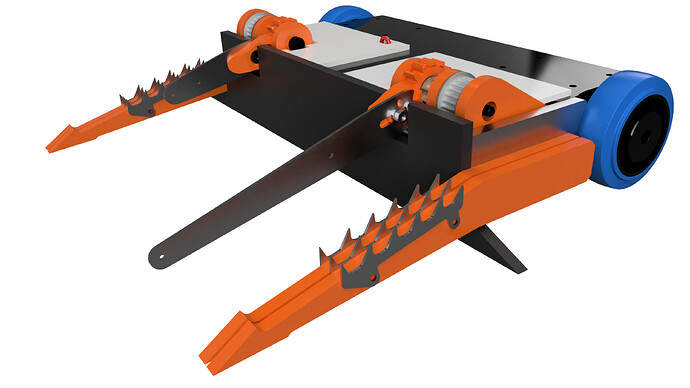

The design intent was to have a dual chainsaw/waggle stick control bot, using as much actual chainsaw parts as possible. The chainsaws are effectively decoration, and the idea was to use the teeth to get more purchase on slick HDPE or metal edges, and provide an entertaining looking robot.

Using cheap brushed mini chainsaws seemed a good place to start, and a few days later my idea started to take shape

I intended to use as many parts as I already had lying around to both reduce cost and ensure I actually get it built, so the construction will be as simple as possible. It’s my first full HDPE bot, as well as my first router based build so this might be a fairly steep learning curve compared to my preferred flat pack sheetmetal.

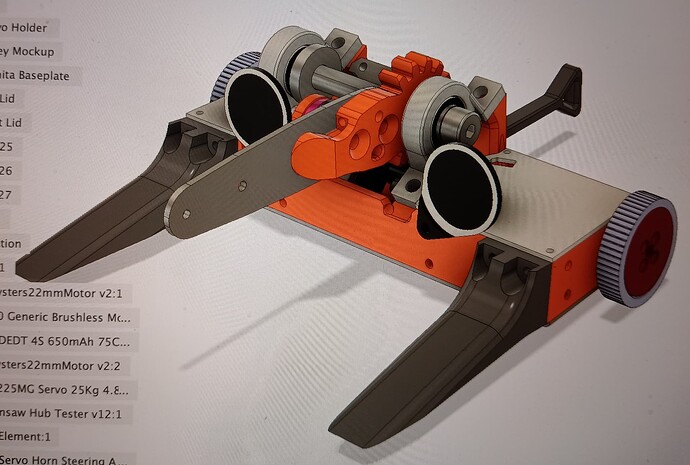

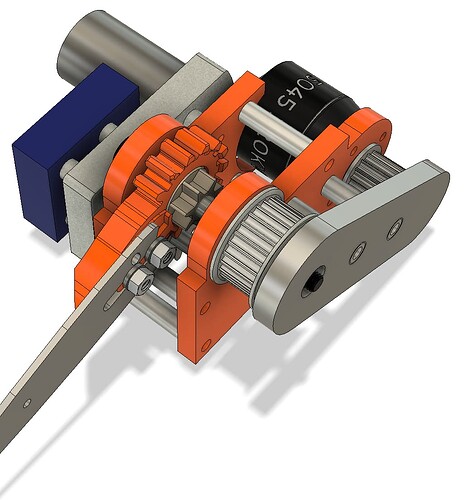

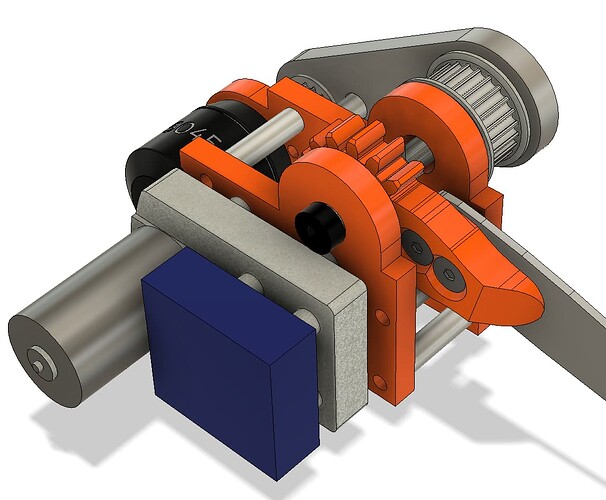

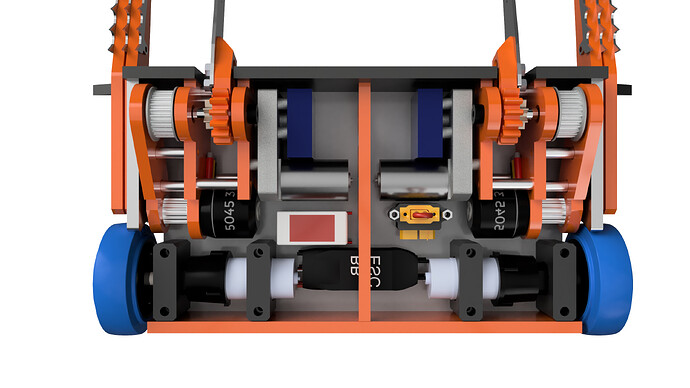

I doubt my initial servo based idea will have anywhere near the torque required to self right, but it’s a start. I’d love to have each “arm” individually controllable, more for show than actual use but I suppose there is also an element of redundancy in doing this. The coaxial lift/chainsaw drive is also due to the fact I’ve got a lot of 12mm shaft parts from other projects spare, so it should help me get moving quickly. I started designing a proof of concept mechanism and as usual it got a bit out of hand…

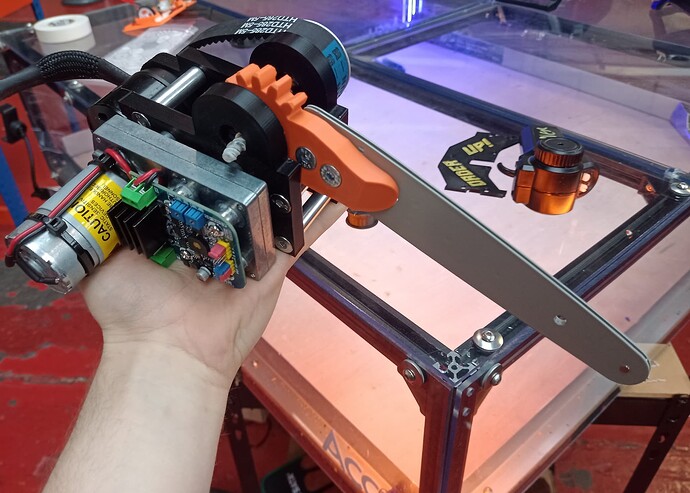

Meet Pochita, the test bed for a single module of my chainsaw drive. I got carried away with the mechanism and worked out it would fit pretty decently into an ineffective beetleweight

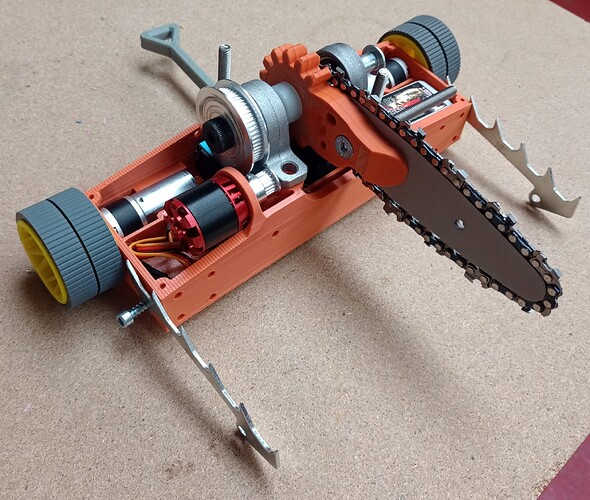

Some printing later and here we are

It’s the 4" bar version, and they go up to 12" on the same mount so it shouldn’t be an issue to change lengths for the feather.

Thankfully it all fit together apart from the weapon shaft, as I misread 40mm as 30mm so the drive flats are too short for it all to fit in the right place, but thats nothing a bit of machining can’t fix. If it all goes well, it should be a simple matter of scaling it up to suit the feather version.