Arm bits!

Befitting the spirit of Bevs, we decided to maximally utilise technology for stupid, and attempted to construct a (bevs)combat-proof 5 axis robot arm atop Felix’s lovely chassis.

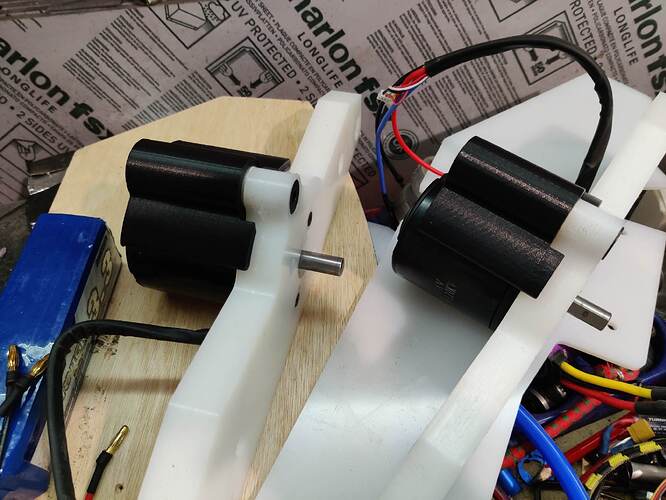

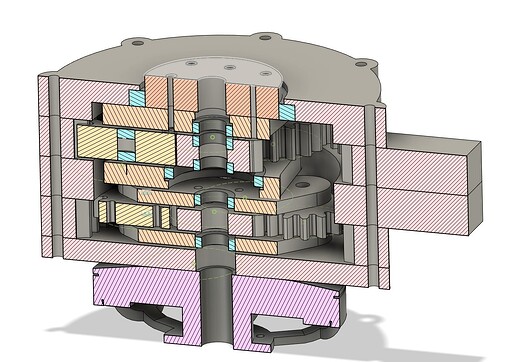

For the first three axis (the ones bearing the most load) I used fusion 360 to design a 2-stage planetary gearbox that could fit to X8308 motors (I had some spare from other projects), and could be made in our workshop (on the mini-lathe and CNC router). Whole lot was Mod 2, first stage used 8mm thick gears, 2nd stage was 12mm.

A load of cheap bearings were bought:

a bunch more HDPE gears were cnc’d:

And the thing actually span pretty nicely!

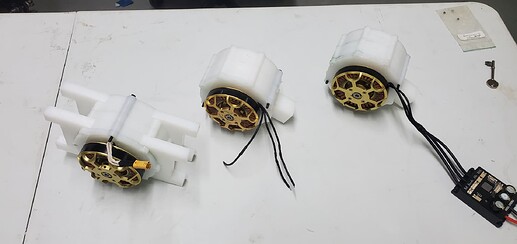

Copy and paste 3 more:

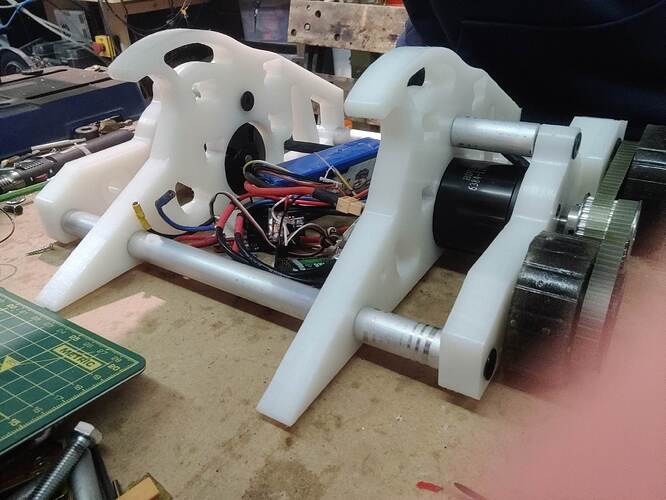

A lot of post-processing later (a total of 30 “toothed friction devices” were cnc’d for these gearboxes!): (One gearbox has a slightly different outer case to jigsaw into felix’s chassis)

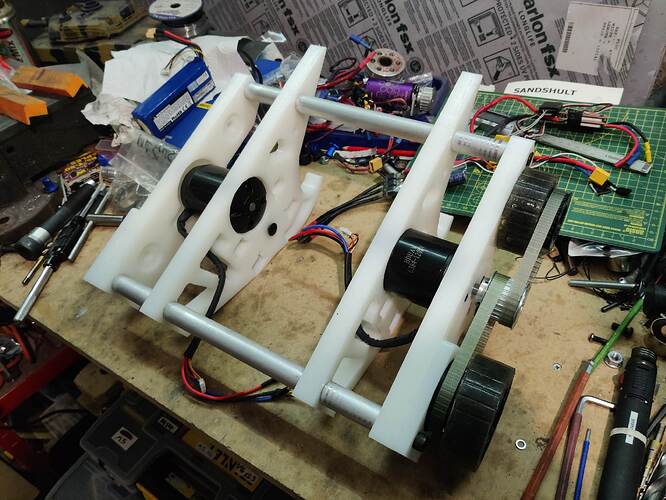

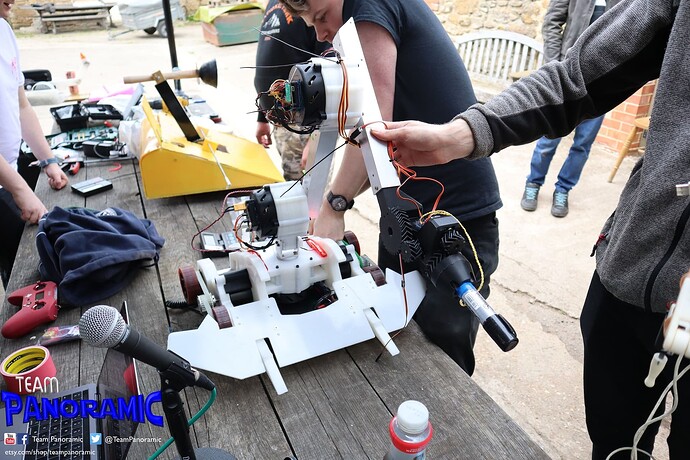

Some aluminium box section and a chassis later, its starting to take shape! We were somewhat running low on time by now, so the final two joints were a hastily-cadded 3D print hacking some random servos to incorporate a 3D-printed spur stage for extra torque and some limited protection for the servo’s gearbox.

(Felix for scale)

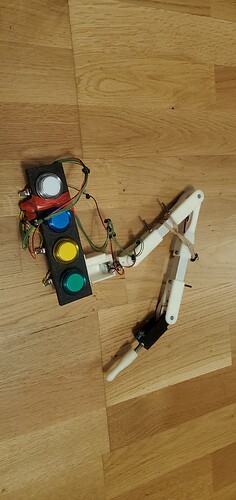

A good time to introduce the controller - essentially a handheld scale model of the robot arm. An arduino nano is measuring potentiometers in each joint, and sending the information to my custom ESC’s using a haistily written serial uart protocol and some 433MHz ebay-special radio modules. The buttons perform various calibration procedures, activate the 6’th servo channel (for the snips) and digitally arm/disarm the big robot arm:

After adding some 3D printed motor covers, some custom esc-encoder motor controllers, and a rapidly tuned PID position-control algorithm, it comes to life! Each joint in the big arm acts like a servo, and tries to copy the angle of the corresponding joint in the small arm. The setup makes for a reasonably intuitive way to control 5 axis at once!

MAGNUM Sharpie:

And the final product! (Thanks to Harry Tee for the photo!)

We had a blast debuting this machine at BBB’s Northdown havoc / 5th birthday party event (check out the event video here), and hope to bring it back in future! - maybe with some better tuned PID, lower latency radio controls for the arm, and maybe a wider array of wacky attachments!

![]() were also 5mm HDPE. the robot also had a couple different attachments. my attempt at a set of wire cutters were… frankly wonderful i mean whofull, but they had the spirit i could tell.

were also 5mm HDPE. the robot also had a couple different attachments. my attempt at a set of wire cutters were… frankly wonderful i mean whofull, but they had the spirit i could tell.