With Robodojo’s inaugural Hobbyweight event in 3 weeks, it’s about time I actually build the hobbyweight that I’ve been talking about since last year’s Elizabeth Day memorial event.

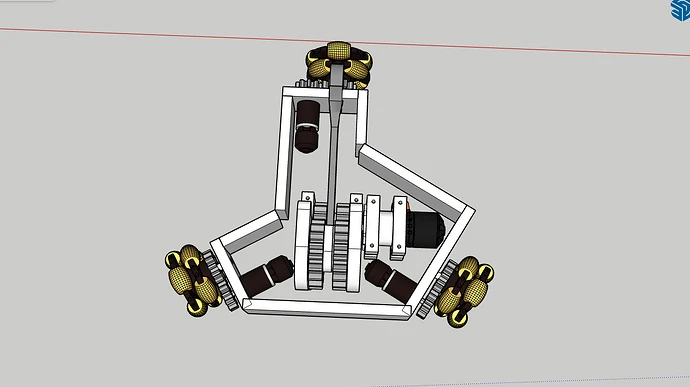

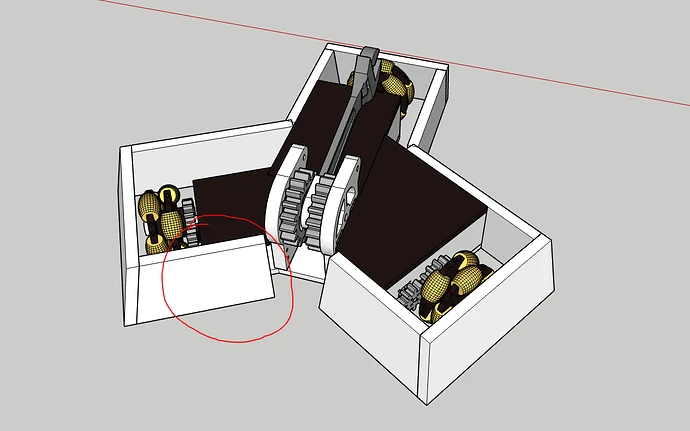

Soon after that event, I started throwing stuff into Sketchup:

The iniital design was this incredibly funky asymetrical shape, in an attempt to remove as much chassis as possible. This was ditched due to the large footprint - more big = more weight innit.

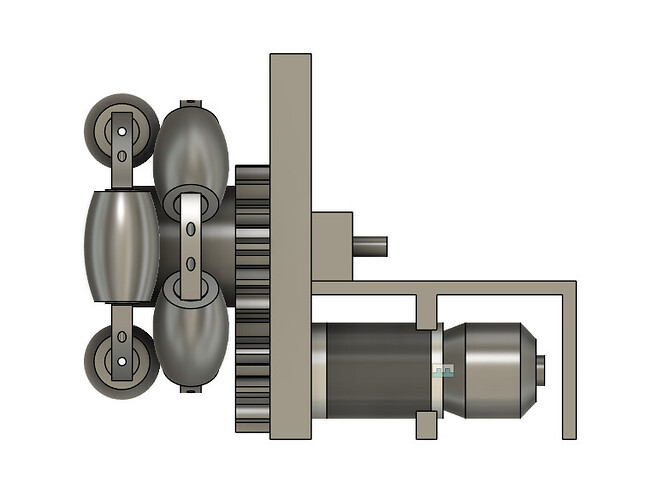

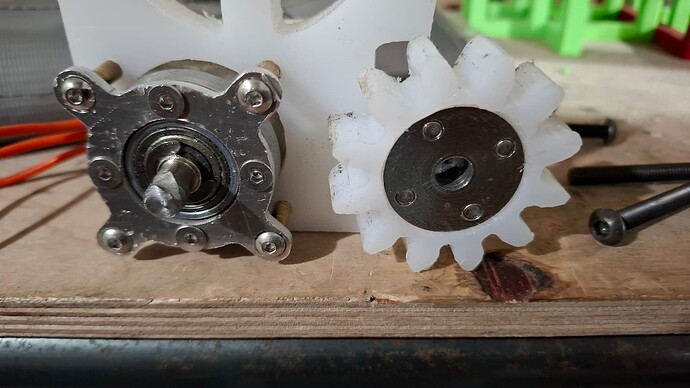

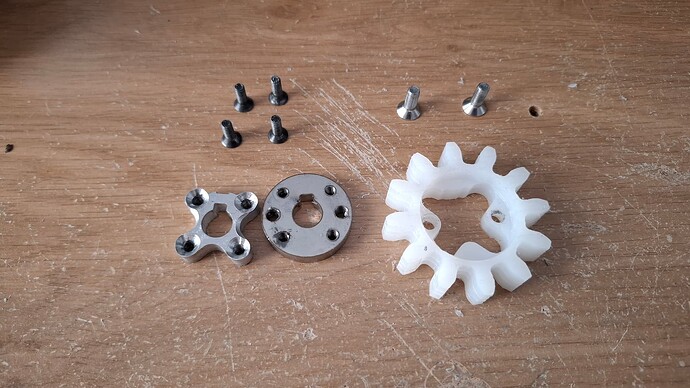

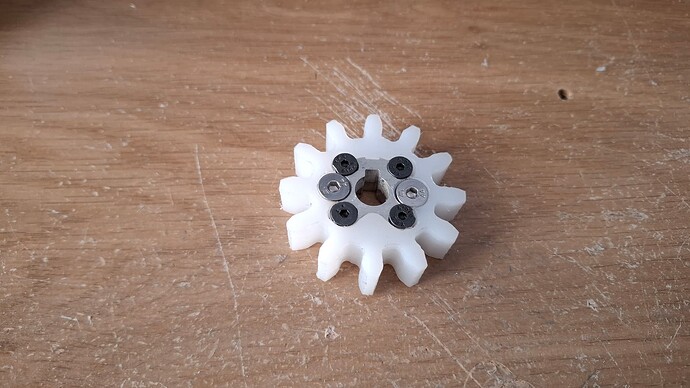

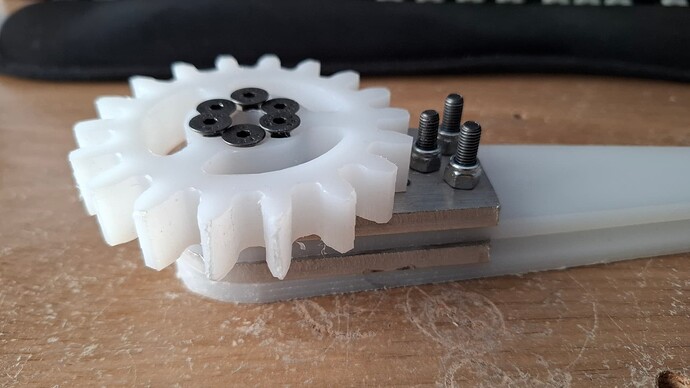

One thing that I have kept from this design in some form is the gear train from the drive motor to the wheel. With only 6mm shafts, I didn’t want to directly mount the wheel to the motor, as a direct hit to the wheel could do a lot of damage to the motor if set up this way.

I planned to use 12mm HDPE for the armour skirt for this, but again would have cost a lot of weight, and resulted in lots of awkward shapes to cut.

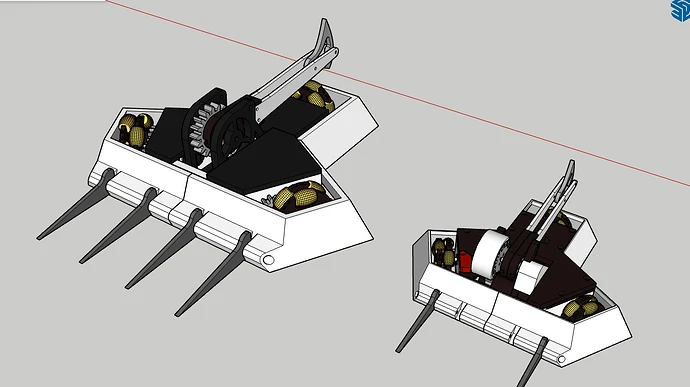

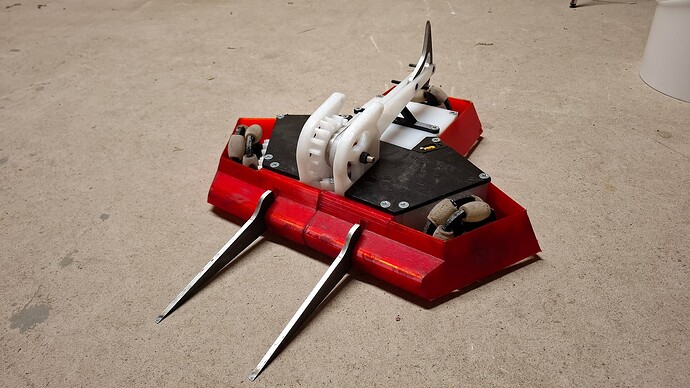

Attempt 2 around last September was to literally scale up the beetleweight design and modify the parts to fit. This was a lot more aesthetically pleasing to me, but I still wasn’t sold on doing that, as now component location was largely dictated by the beetle design.

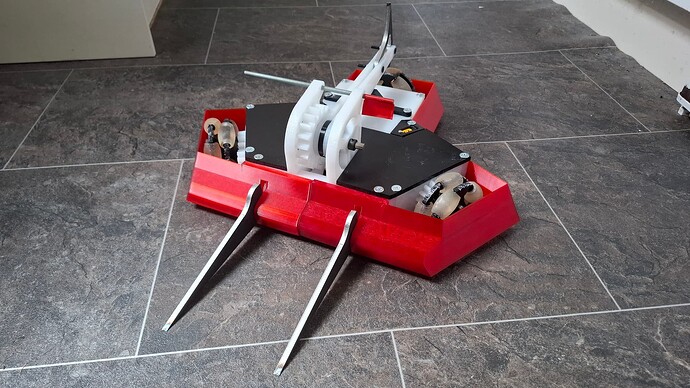

I did a Lasered order at the start of this year in preparation for actually building the bot. I more or less scaled up the fork and axe head from the beetle 2x.

Admittedly, the forks are chonkier than necessary, if I get more cut, I’m going to remove some material from them.

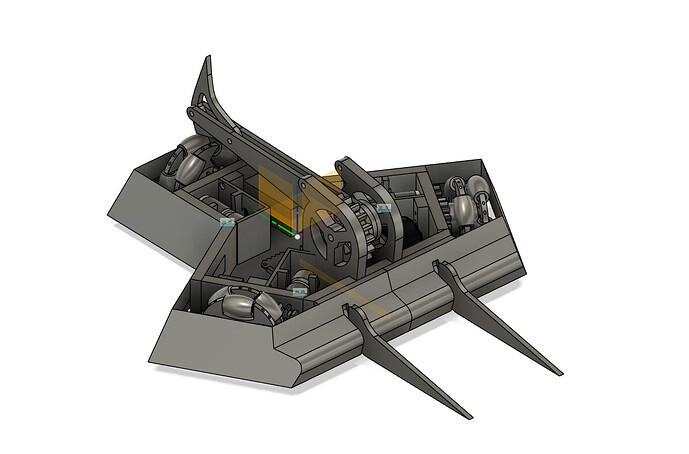

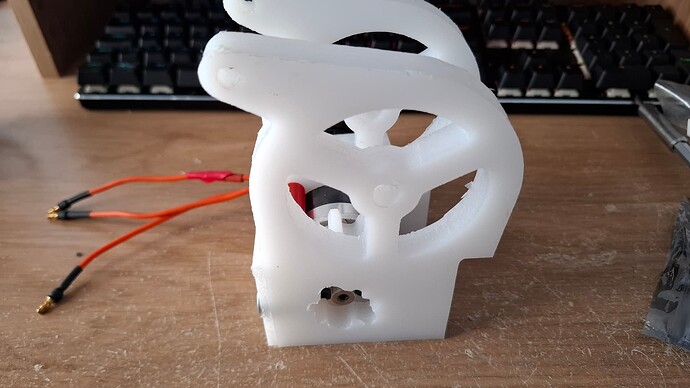

A couple of weeks ago, I finally got off my backside and started to make a Fusion 360 version of the CD. This time, I just made it from scratch, learning some of the key features of F360 along the way - components and the timeline really helped here!

Still a few things to sort out - the most obvious is the lack of top plates, but some more detailed work like mounting/support for the weapon motor and TPU enclosures for the electronics, but happy with the general design now.

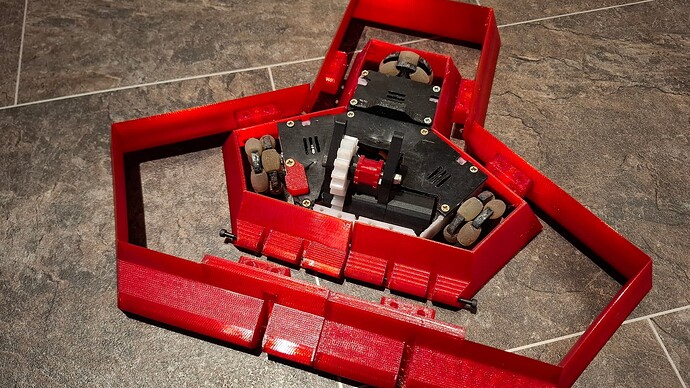

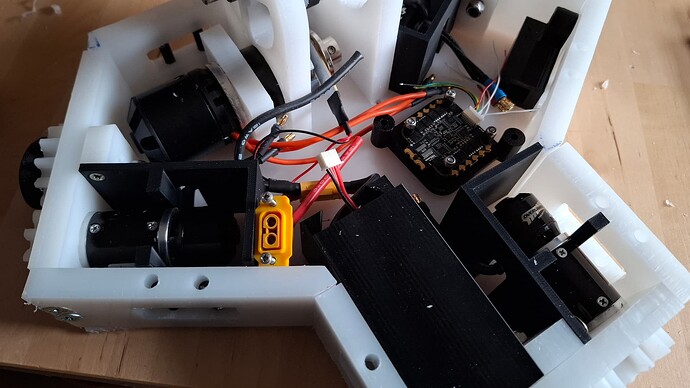

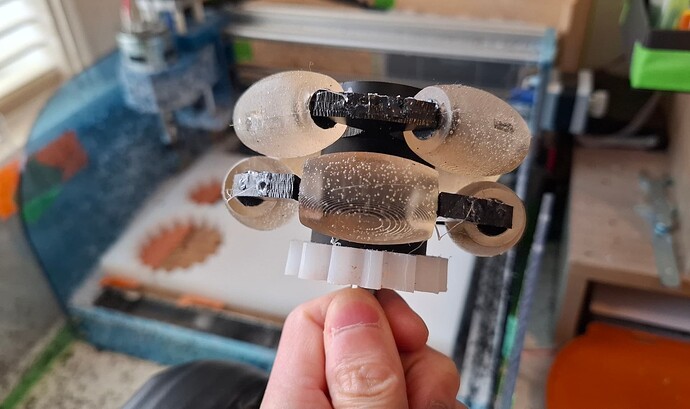

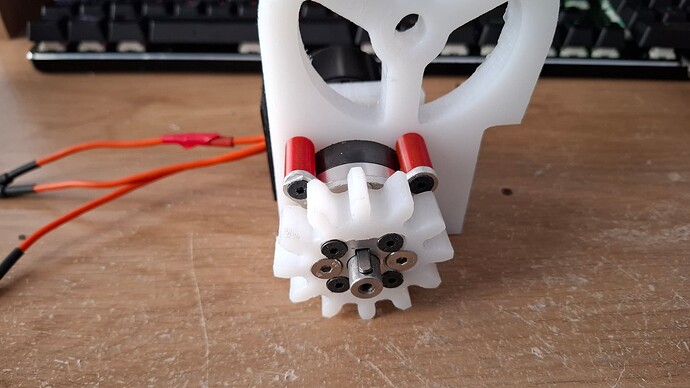

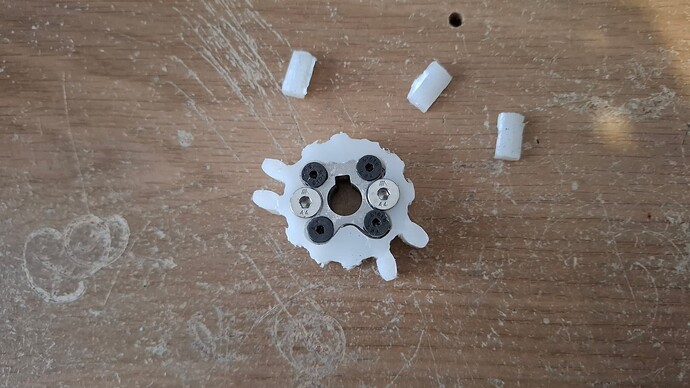

The motor is an Overlander 2830 1300kv coupled with a 14:1 gearbox, the same as what is running the weapon on the beetle (horray for reuse!) Wheels are 85mm nominal diameter (89 with the rollers), and will be constructed from 6mm HDPE plates for the roller plates, and PLA-ST spacers. The wheel runs off a 8mm shoulder bolt. The whole motor setup is a single component, and is identical for all 3 wheels, so I can have a fully assembled drive pod ready to go if I need to replace one in a hurry.

The weapon uses the Ranglebox Saturn and 14:1 gearbox combo I used in Accept Cookies last year, and in Overclocked V1. This drives a 1.5:1 HDPE gear reduction to the axe, with 2x6mm HDPE arms to the 6mm wear plate axe head.

For control of everything I am trying out a Sequre E70 G2, a 4-in-1 AM32 ESC that advertises 70A per channel. It lacks current limiting to my knowledge, so we’ll see if it actually matches the spec. A Radiomaster R86 and BEC rounds out the electronics, powered by the 4S LiHV 1700mah battery I have from Accept Cookies.

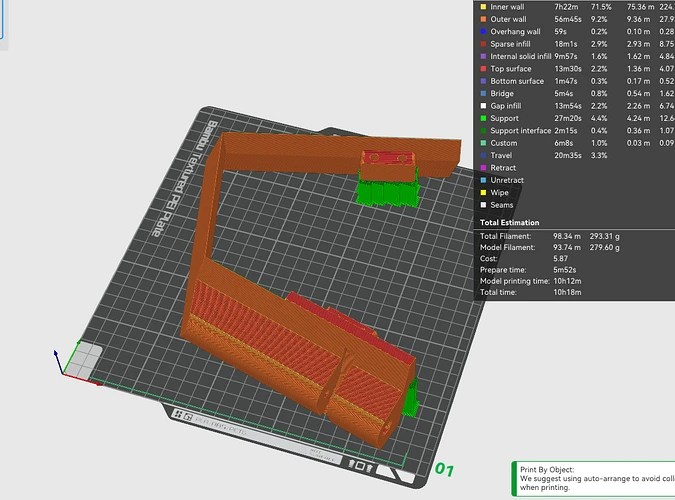

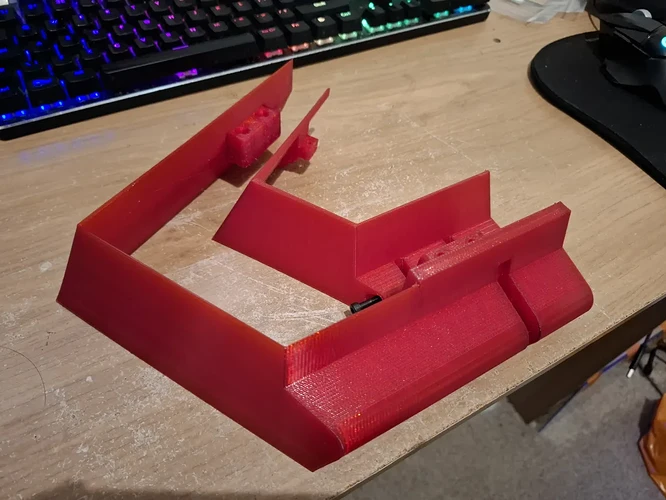

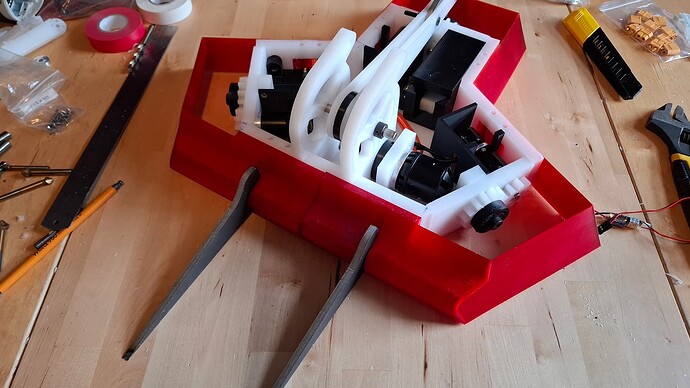

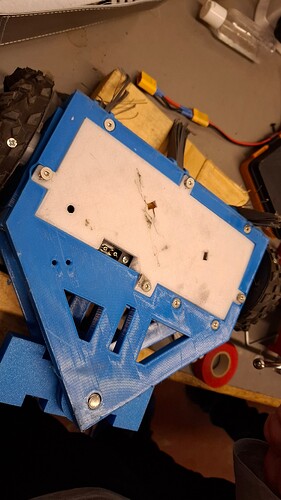

Yesterday I printed off the first part of the armour skirt, which was juuuuust small enough to fit on my print bed.

It’s pretty hefty!

This one will be relegated to the spares pile though - this was done before the CAD above, so the fork mount is 20mm closer to the centre, and the corners have curled up a bit (which should be fixed with some brim ears).