Hello there!

Haven’t been on a forum for quite some time and woke up pleasantly surprised to see that one for the Bristol Bot Builders had been made! Thought I’d make a sort of build log/event diary for my 150g Antweight robot, Printed Bots Still Suck!

It’s probably the most interesting of my robots despite only being a wedge because it took the longest to design and I plan on evolving the design further!

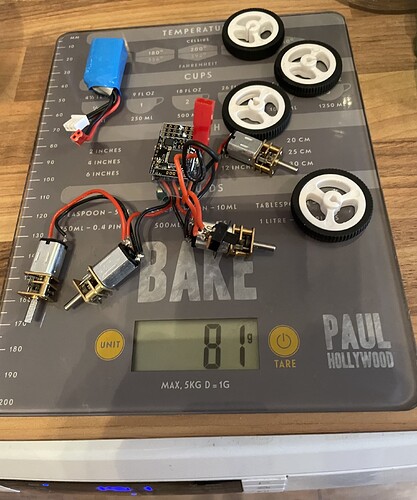

I started out with a pile of guts for a 4wd Antweight, your basic internals, nothing fancy at all which all came to a slightly hefty 81g.

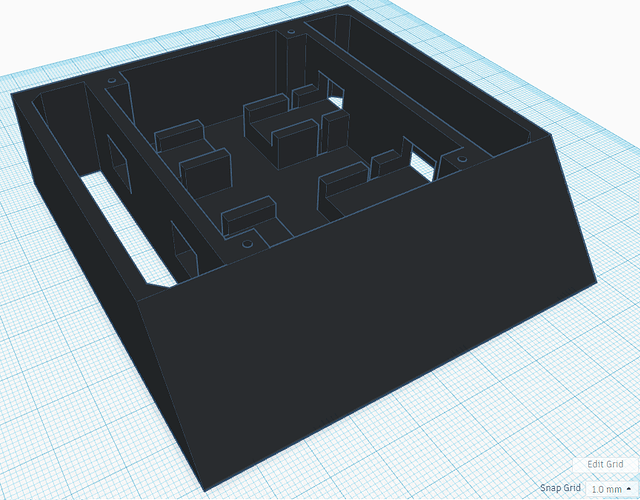

Before this I had never used any sort of CAD program to actually design an entire robot from the ground up, only to make a few rough prototype designs for otherwise vapourbots. I decided to take the plunge instead of just downloading a chassis from Thingiverse, booting up TinkerCAD and whipping this initial design up within a few hours.

Now it’s probably worth noting that I don’t have a 3D printer, nor any software that can slice a file for printing. Heck, I don’t even have a paper printer at the moment! Thankfully though Will Caddy does and when I sent the files to him, he quickly found out that it was grossly overweight!

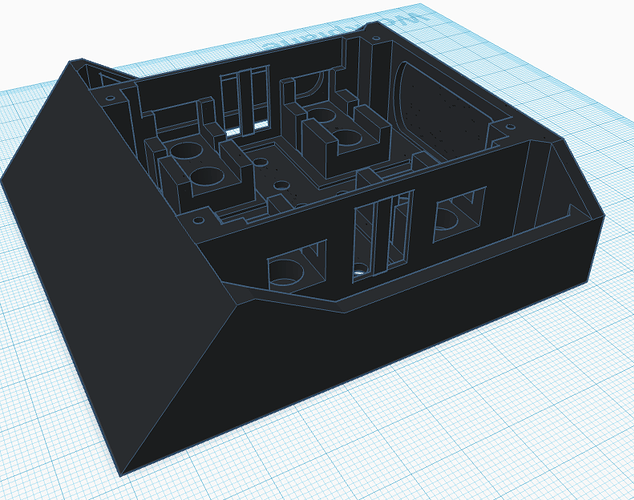

The first weight saving measures I took were to hollow out the wedge, with it ending up about 3mm thick on all sides but this still wasn’t enough so then I took to hollowing out the inner walls and making them thinner. All in all the chassis went through about seven revisions to get it in weight which included lowering the wheelguards, swiss-cheesing the chassis with holes, hollowing out the wheelguards and rear wall, hollowing out a section of the main chassis and even making the lid slotted rather than solid and after 7 (yes 7) revisions, I had a finished chassis that was in weight… albeit a little ugly!

Will printed it for me out of Polycarbonate which I didn’t even know you could 3D print and soon enough I had the finished thing come through my letterbox (thanks Will!). It wasn’t a perfect design by any means, I had to swap out the battery for a slimmer one just for it to fit in and I had miscalculated the height on the motor mounts. You see, they were originally supposed to fit into the channels on the motor mounts and be fastened with zip-ties but I soon unfortunately found out that they left the robot beached. with only two wheels on the ground so instead I had to press-fit the motors in and tape them in place with that most handy of all tools, Duct tape!

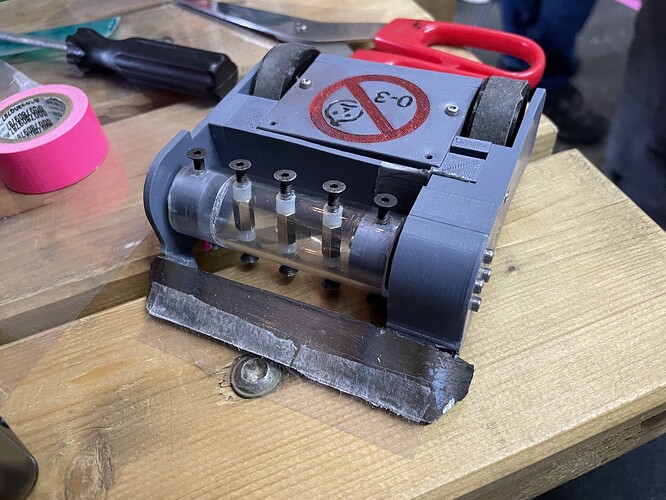

This was it fully assembled with a juicy 6 grams to play with… woohooo! I decided to add a small strip of 1.5mm polycarbonate on top of the wedge which I used my Duct Tape to mount. I sharpened it down with sandpaper and mounted it as close to ‘ground-scraping’ as I could to be effective without acetate for BAnts. perhaps not the most sensible idea but it held up at the event!

Speaking of the event, I competed with this robot at the Pub Social in June of 2022, christening the robot ‘Printed Bots Still Suck’ (P.B.S.S. for short) with a Sharpie, based off of the phrase ‘Pushy Bots Still Suck’ created by the great Brian Nave.

The event went fairly well, going 2-2 in the 1v1s and 2-1 in the 2v2s. My first win was against a rear-hinged flipper made by Jason that I just bullied around the arena for the full 3 minutes, almost blowing up my ESC as the Duct Tape I had used to mount the motors got caught in one of the gearboxes, leaving me with three-wheel drive. Then I fought a front-hinged flipper made by Sam Robbins which I really shouldn’t have won as he had the lower wedge and I got stuck in the wall at one point but my opponent kindly got me un-stuck (thanks Sam) and after some tussling he ended up getting overturned by the arena flipper and unable to self-right despite my efforts to assist him.

After this my third fight was against Jack’s (I think) drum-spinner which was one mean robot. I managed to flip him after a hit and then he managed to flip me upside down and then knock me again onto my back where I was stuck and immobilised. It was a pretty quick loss but the damage I took was fairly minimal thankfully. One of the supports on the lid had snapped and there were a few tiny knicks on the back but nothing major at all which was great! Loved the 0-3 Sad Onion on top too.

My final match in the 1v1s was against Morgan’s scary looking hammer-saw which I was initially going to forfeit against due to my lid having pretty big gaps inbetween it. I MacGyvered up some extra protection on top with a scrap bit of Polycarbonate and (what else?) Duct Tape and headed into the arena. After a bit of pushing and shoving I soon found out that the little holes on the bottom of my robot had a habit of getting hooked by his forks which meant I was stuck on them for the majority of the fight but thankfully my polycarbonate lid came handy in blocking his attacks, meaning that the only damage I took was to the wheelguard and a tyre. I tapped out after I noticed one of my motors came lose, amazingly for the first time in the event and unfortunately this meant I didn’t qualify for the knockout stages.

I really don’t remember much about the 2v2s unfortunately other than adding a polycarbonate tail to stop it from getting stuck on it’s back. Me and Greg’s 2-1 finish also wasn’t unfortunately good enough to qualify for the knockout stages either but I still think I had quite a successful event for my first 3D printed design. Here’s a pic of the robot at the end of the event. Note the zip-ties on the side of the robot which I believe I added after the second fight in the 1v1s to help it stop getting stuck on it’s side

I was supposed to enter this robot into the March Social this year but unfortunately fell ill on the week of the event, meaning I had to pull out but I will be back for the next one!

Next time around I’d like to make it so the robot is unable to get stuck on it’s back or sides, has a better designed wedge with sloped sides for better deflection, has a better lid and definitely lower the motor mounts so I can use zip-ties to keep them in place!

I hope this build diary will be helpful to any new designers out there!