Hello! Christmas is here so we have a bit odf time to write up what went well and what went badly with robots this year. With Toucan in a fairly good spot, i decided to try to build a KE beetle for my second and being me, couldn’t make it normal, or even remotely easy for myself.

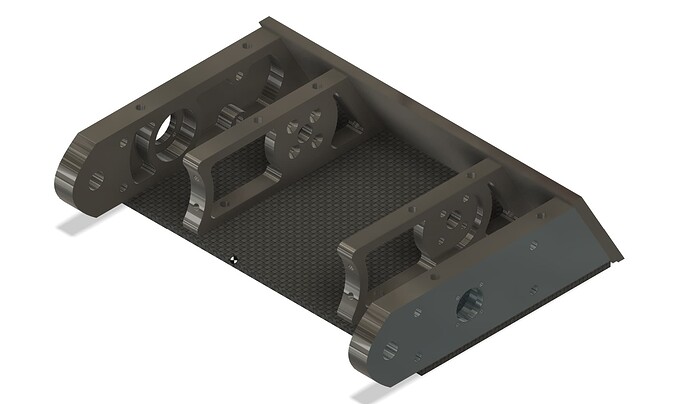

I decided early on to make a WIDE drum, pop a weapon motor on each side, slap on a drive and go for it. That simple. Hah!

Some days of CAD and a call to PCBWay later i’d got this lovely thing milled - 140mm wide, 35mm Diameter 4340 Alloy steel:

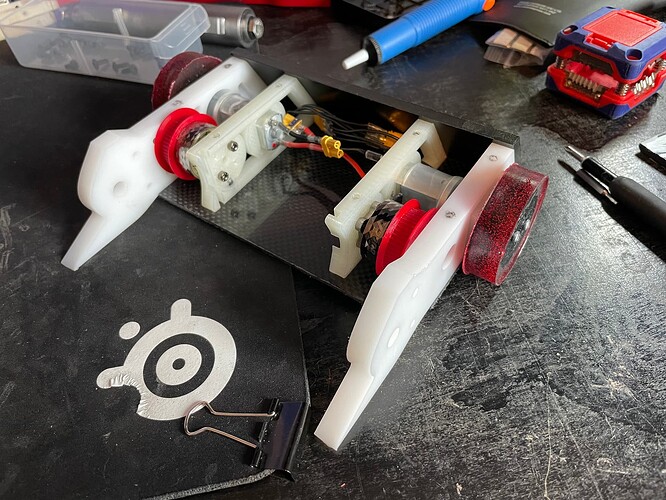

The whole bot’s an experiment: i bolted some geprc 1804 motors onto spare BBB 22mm gearboxes for the drive, they are super tiny:

Next, I got a pair of 2626 motors to power the drum - they looked cool and I had no better ideas at the time.

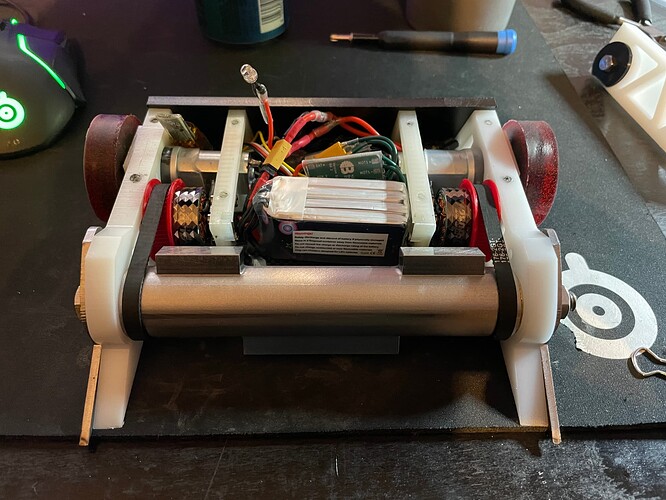

i wanted to get the wheels relatively far forward for balance. or soemthing, so once parts arrived we could mock up a chassis in like this :

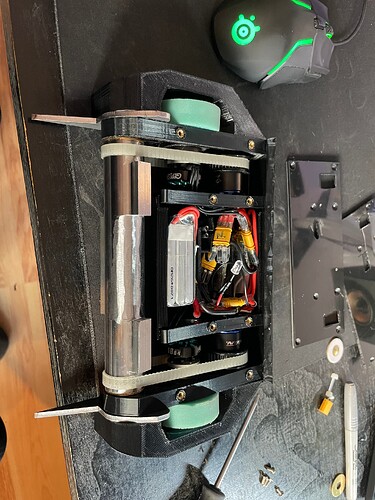

Then fit the electronics in with a bit of a squish, and go for a spinup test - in a test box of course. Always in a test box.

At this point i’d been through aload of PLA chassis test pieces, had the internals laid out and swapped over to Polymaker CoPA nylon, i’d heard it was supposedly super strong and being an experiment, decided to give it a go. External bulkheads are 10mm thick and the internals 8mm - all printed with 4 walls / 35% guroid infil.

After some fiddling with ESC’s, it span up relatively smoothly on 3S. Even getting it this far felt like a huge achievement.

More to follow later…