So uhhhhh, long time no see!

For the past while I took a step back from superior violence due to my other bots being far more feasible to be constructed and probably more fun to drive. Along with this my ability to use cad was not as good as it is now, so the previous designs were not the best.

Also, then I didn’t have a test box, so wasn’t able to do any testing of it spun up. I hope to be able to show its first spin up test soon-ish!

What has changed since then:

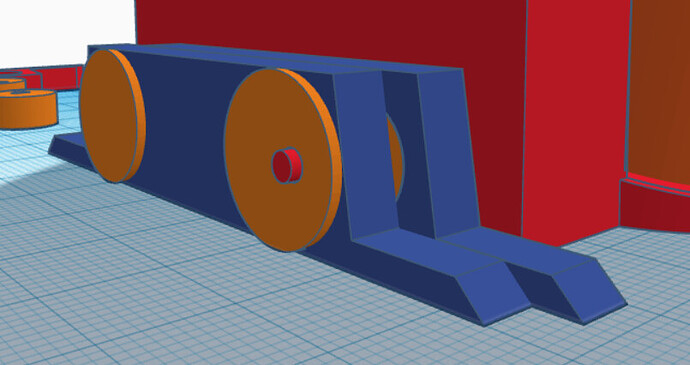

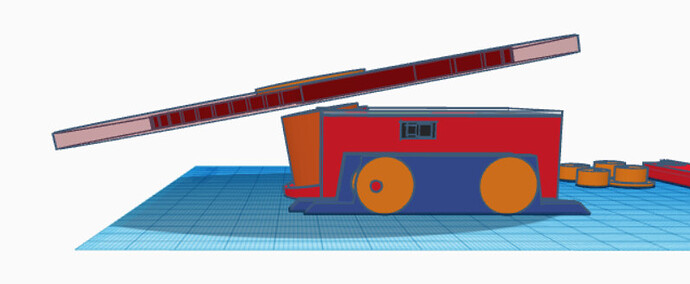

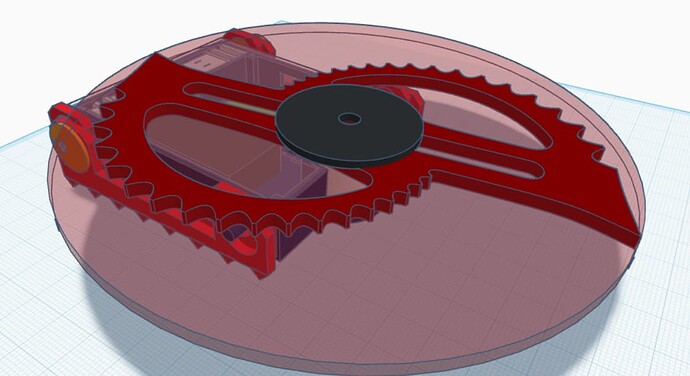

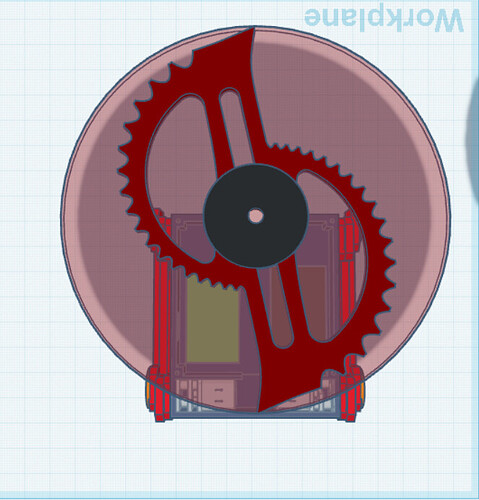

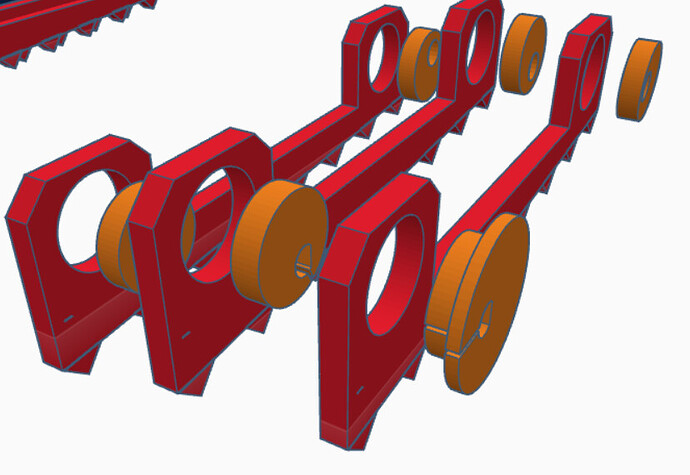

Firstly, I though far longer and harder about the shuffling mechanism and took some inspiration from this video by broken link robotics where he builds a shuffling ring spinner with an 82g titanium weapon. Now my shuffle pods will have 3 legs per side and each leg will have cleats to attain grip on the floor as pictured here:

The slant originally was obtained by angling the motor mount, but it was a massive hassle to print, design and modify, so now the entire bot slants with the shuffle legs.

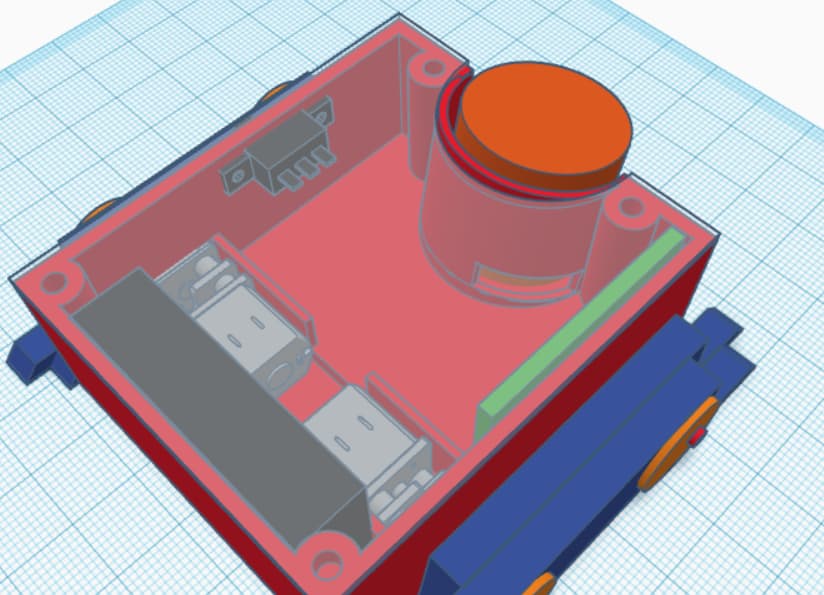

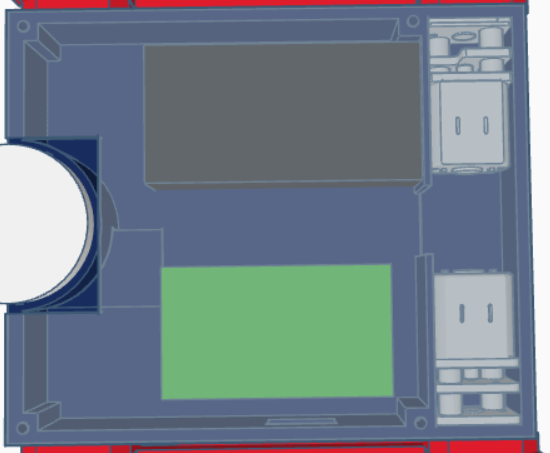

secondly, I have ditched the whole building in the third dimension shtick in exchange for what I always end up doing; flatpacking my components

This allows for easy cable management and due to all my components being 10mm tall is quite compact.

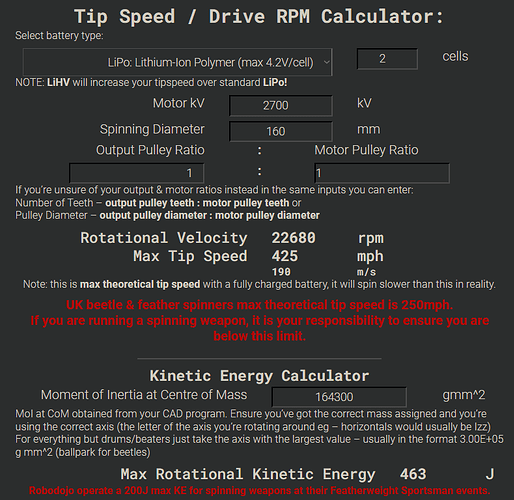

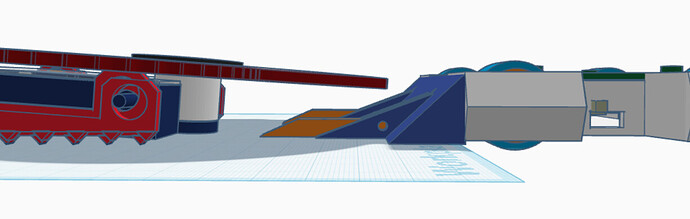

Thirdly, I have branched out from the basic BE1806 motor found on the BBB store, now using a GTS-V2 1506, which saves on weight, space and makes mounting easier due to not needing a 5mm shaft adapter. It allows for a higher, 4300KV, making my max theoretical tip-speed now a whopping 592 Miles per hour. Why? Because bigger number better, and the addition of a tip speed limit has given me a number to reach. Speaking of the tip-speed, I discovered I had mis-measured the blade and instead of it being 160mm it is actually 140mm, meaning it does not fully cover the rear, and leaving room for a potential self righter if there is the weight by the end.

Fourth, I switched from heatset inserts to self tapping screws because I am lazy and in my experience, the inserts just rip out or some part of the frame breaks and I have to redo the inserts, making self tapping screws faster and more convenient.

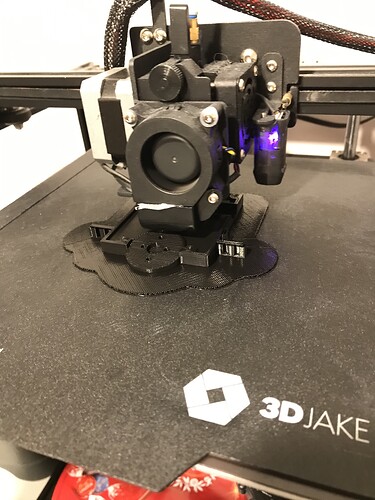

And finally, I am switching from PLA+ to Prusament PETG for increased strength and durability

I intend on bringing it to the Bristol event in march 22nd due to the reduced size and number of pits, and from there bringing it to ORCS 8, 9 and 10

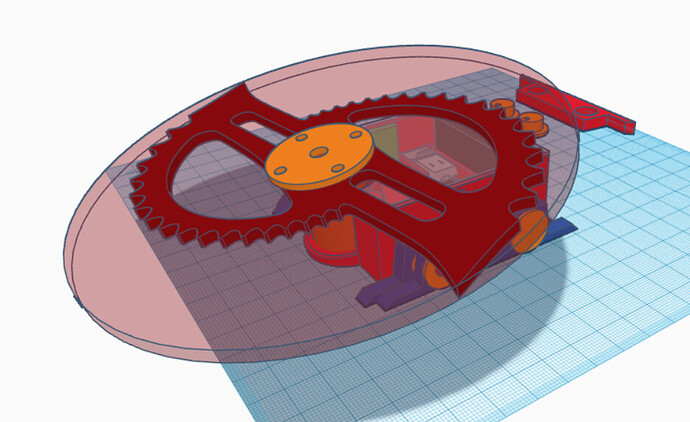

Anyhow - enjoy some of the full cad:

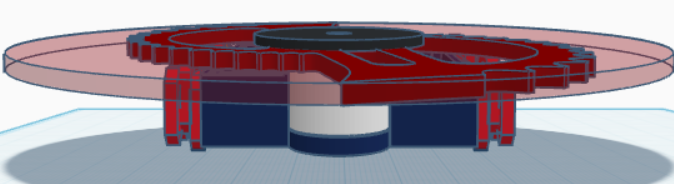

Full view

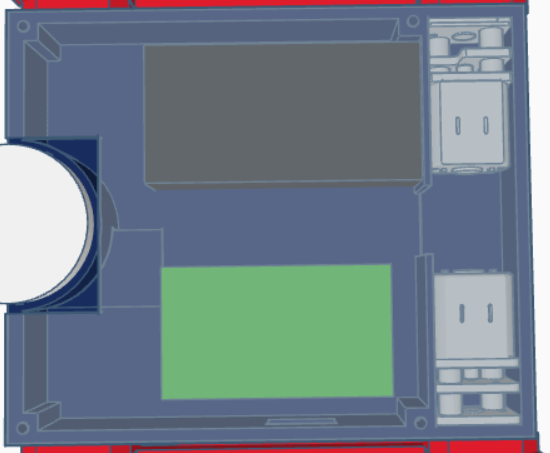

Top down

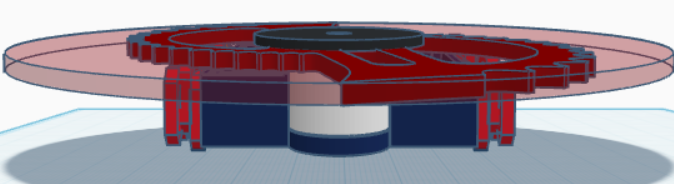

front on

Blade height as compared to an old version of my wedge-bot Sir Googly, which had 24mm wheels

Exploded view of shuffler mechanism