Hey all

Ive never really done build diaries for my robots and this thread will probably be more a collection of photos of what Im up to after this, but ill try (and probably fail) to keep it updated lol

Im fortunate enough that my workplace is sending me to work on the east coast of America for the rest of the year at relatively short notice, unfortunately that means I have a month to design and build a US beetle to take to NHRL and GSCRL that I can service and work on with a minimal amount of tools.

For those that may not know the US weight limit for beetles is 3lb or 1.36kg not our 1.5kg so i need to build from scratch!

My only brief for this robot was to be somewhat tryhard but also not characterless

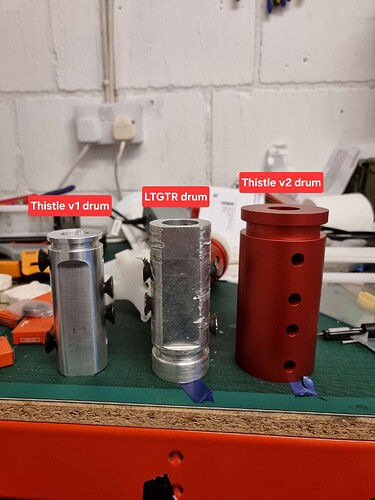

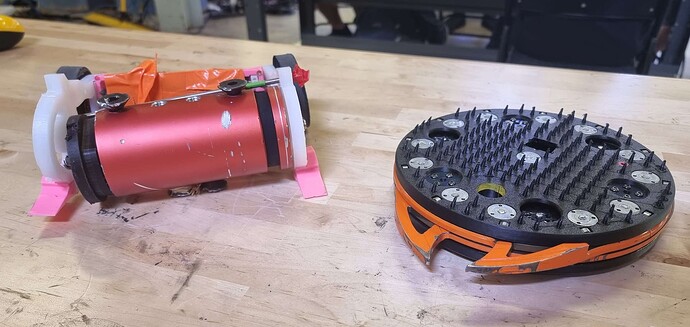

I have recently purchased a beautifully made drum from Felix T and at 430g its a chunky boi

pictured for size next to a repeat max and Let The Good Times Roll’s drum if you remember that pre-covid one hit wonder which now lives gutless in a draw

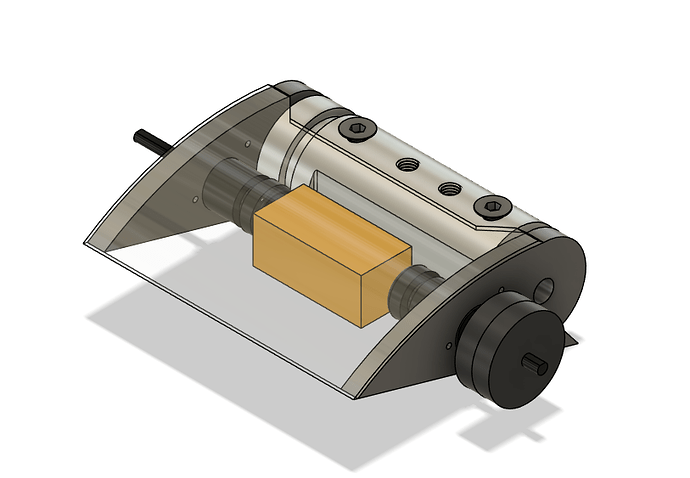

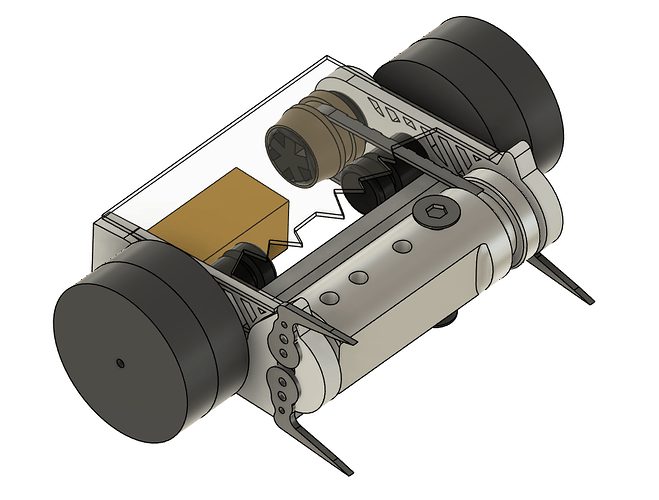

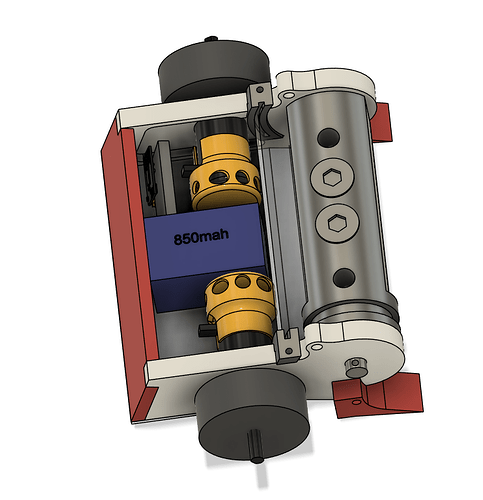

Anyway here are some absolute mistakes of cads that helped me narrow down my thought process for the final design

A fan of the shape but not the fact that if I wanted the curved lid to act like a wedge at the back and as top armor that had a right to be called top armor, polycarb wouldnt cut it. Anything else stronger bent that way sounded like too much of a stress on my weight limit, time scale and wallet.

I hated this halfway through designing, too boxy, 0 character, 3/10

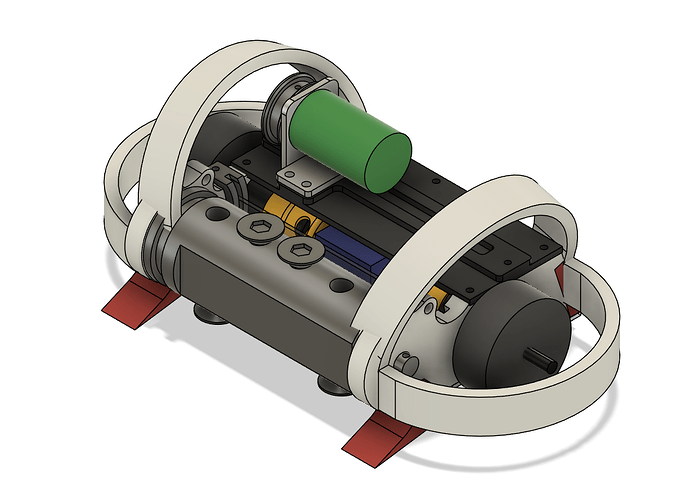

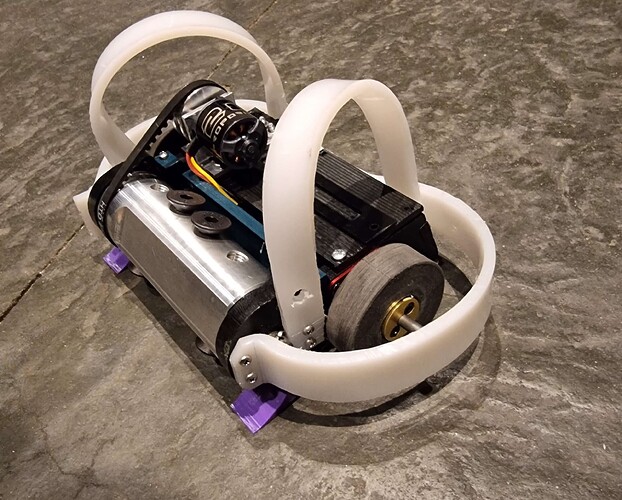

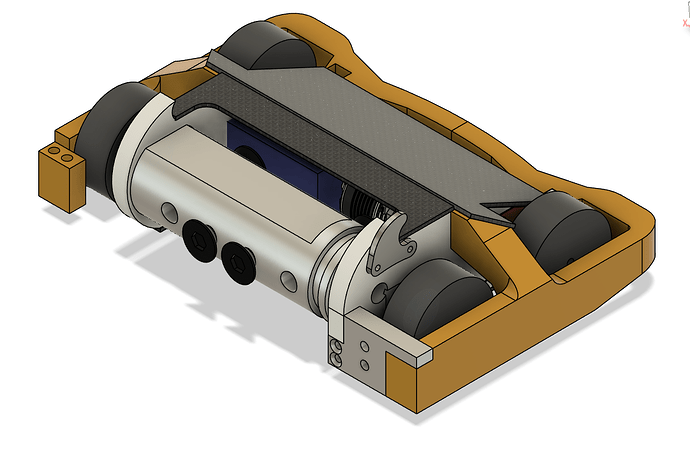

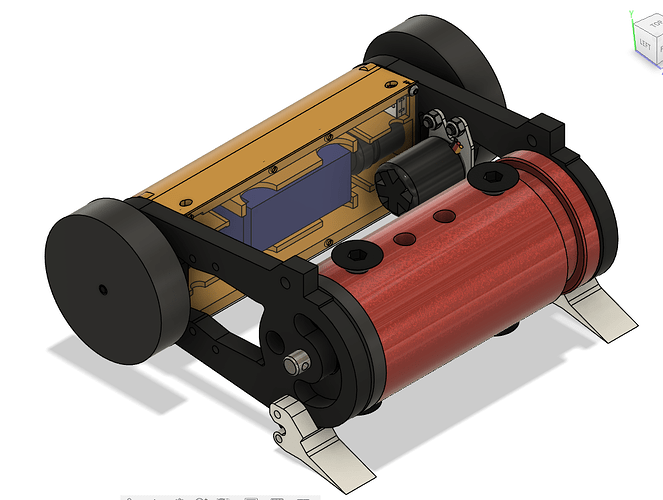

The final design:

I designed this in 3 hours in a caffeinated blur.

All the hoops clip cos I dont have the skill for that.

Just imagine them beautifully curved with a heat gun and attached to the sides of the frame rails.

I slapped the weapon motor on the top to make the body as small as possible so I could save weight, drawbacks be damned, im quietly confident in the rollover hoop meta despite them falling out of popularity about 10 years ago for probably a good reason but whatever.

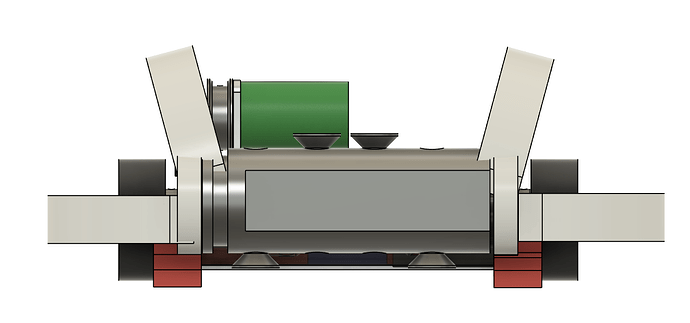

Front veiw.

I can spot so many things that dont quite line up or are missing, itll all be fixed in the garage I promise.

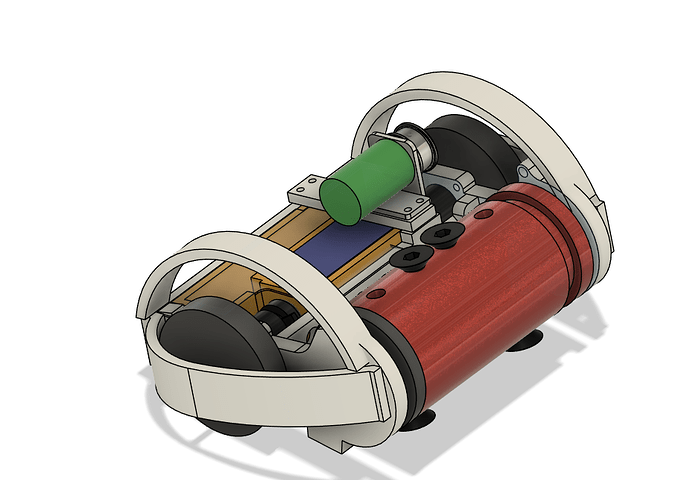

The internal veiw. Its gonna be toight. I am not looking forward to wiring this thing.

The big yellow things on the drive motors are some TPU motor guards I designed which Joe M is printing for me. He also informed me that they go on but don’t come off lol

Hoppin has cut the frame for me already so the next bit of this will come after Ive cleared some space on my workbench to start building

hype

specs for those who are interested

-Drive motors : Repeat Max Brushless Planetary 24mm Gearmotor

-Drive ESCs: BBB Beetleweight Brushless Drive ESC

-Weapon motor: 2845 3650kv X-Team OR if i run out of weight the backup is a

3000kv Propdrive v2 2836

-Weapon ESC: AM32 Aria 70A Brushless ESC

-reciver: Flysky 4 Channel Receiver

Uploading: 4d3317fefac1f78cc3a3e9f6f586b17817011509.png…