I’ve been meaning to write up my various antweight builds so it’s time to stop procrastinating. This post will be a bit of a retroactive build log since it covers about 18 months of tweaks and improvements.

Time for Crab!

The first of my current stable of antweights is Time for Crab! This guy started off as a silly idea based around an N20 motor with a leadscrew. This worked well enough, but the fastest leadscrew motor I could find was still very slow and the 3D printed fitting at the other end was rather fragile.

Running this at our first mini robot event at Nottingham Hackspace it also became apparent that the clamshell body was a problem. It took a full 5 minutes to get the batteries in and out, and pinching the wiring was extremely when closing it up (especially in a hurry) was quite likely.

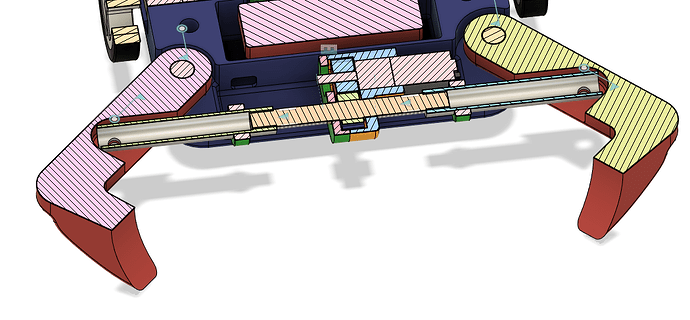

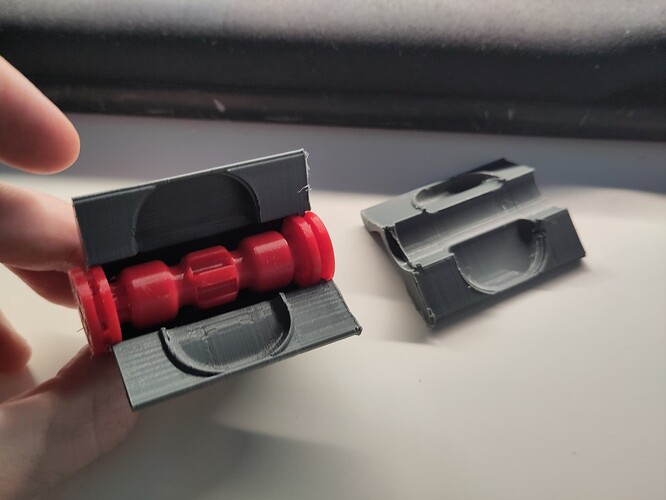

The slowness of the claw mechanism was the main weakness however so I ended up designing a new mechanism using some custom turned parts. The claws became symmetrical with a turnbuckle mechanism in between. Some hex barstock was turned down at both ends leaving a small hex section in the middle that serves as a hub for a gear. One side has a left hand thread and the other has a right hand thread so turning the middle section pulls in or pushes out the claws. There’s a floating gearbox that’s prevented from turning by the chassis which holds a low geared N20 that drives the claws.

Time for Crab! has evolved quite a bit over 18 months or so of events. It now has squishy TPU claws, with various geometry tweaks to improve the behaviour when grappling opponents, and the much needed hatch to make battery swaps and basic maintenance much less painful.

It occasionally gets zombified when the googly eyes take a hit.

Big Loader

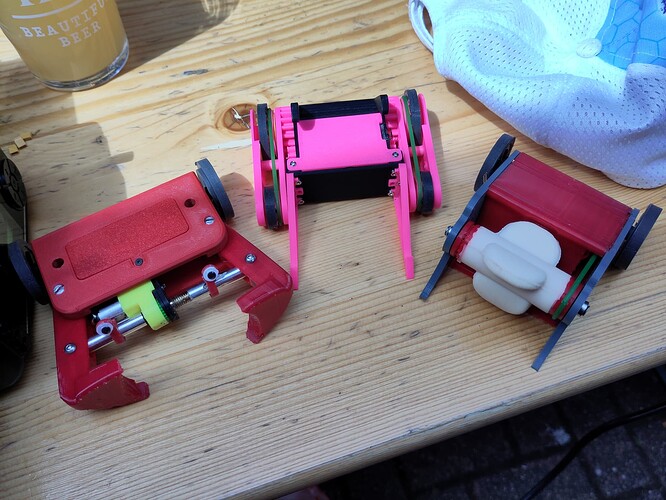

Big Loader started off as an idea about using a dynamic centre of gravity to make a good lifter robot that would fit into a 4 inch cube, but eventually pivoted into a slightly silly robot that can flummox grabby control bots by twisting out of their grasp, but equally has had issues with unconventionally exiting the arena by climbing over the walls due to driver error.

The first version had the motors mounted in a tubular section that joined two drive pods, with a large gear built into it. The rest of the robot was an L shape that the tube ran through, with a scoop at the front and the electronics and battery in a box directly above the drive motors.

A motor under this electronics pod drove a pinion that rotated the drive section relative to the rest of the robot. Long wires to the motors would wrap around the drive tube and eventually prevent it rotating any further.

The idea was that as an opponent was lifter the centre of gravity would move backwards providing counterbalance to help lift an opponent of the same weight while fitting into the 4" cube in the resting position.

This never fully worked, partly because of the scoop design, but mostly because in the default position the robot would flip tilt backwards as it started moving. It was possible to work around this by rotating the drive pods 180 degrees after the start of a fight to move tracks behind the main body of the robot at which point it could still be a very effective pusher.

It took a couple of attempts at redesigning Big Loader before I settled on an alternate configuration worth building.

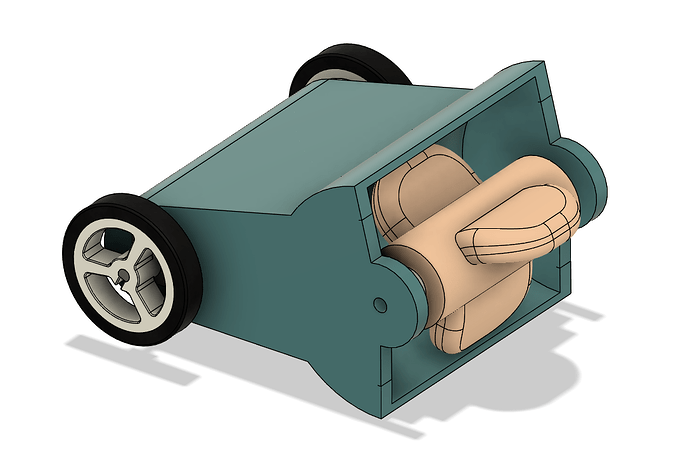

Big loader v2 kept the 360 degree rotation while losing the tall electronics box. It also got rid of the issue with twisting the motor wires by keeping the main chassis and motor pods in the same part of the robot with the passive scoop being the only part that rotates.

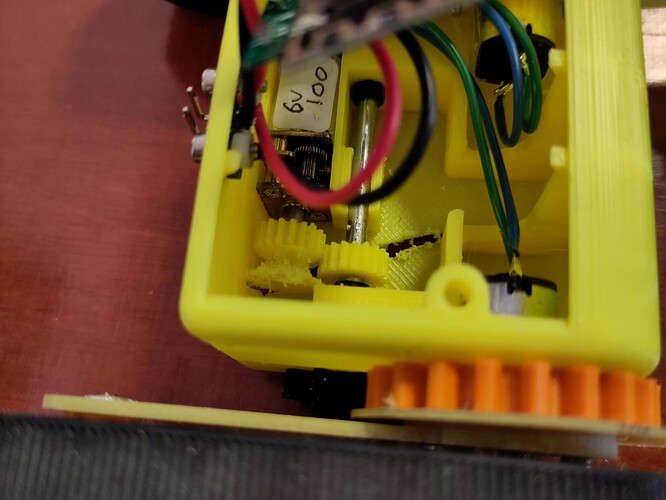

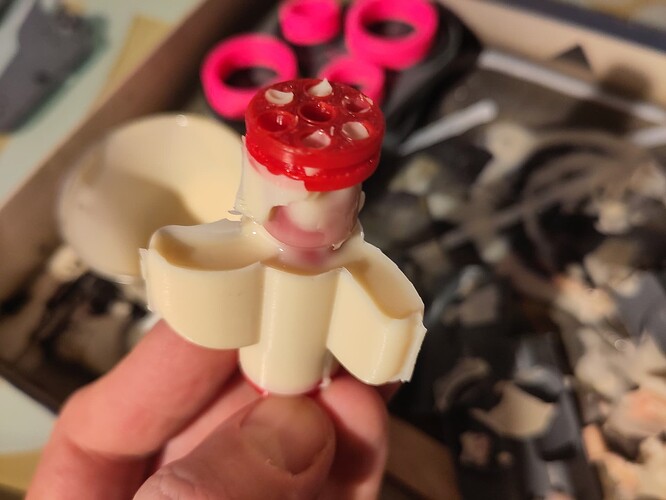

The motor pods and scoop arms are made from FR4 PCB material of various thicknesses to keep them as low profile as possible. 3D printed gears interlock with a 0.8mm FR4 scoop arm, and rotate around a 3D printed hub. The motor sits inside this hub and the drive pods plus a small spacer keep the scoop arms captive. It’s probably best illustrated with this all 3D printed prototype. The aluminium shims turned out to be overkill so the current version has PLA running on PLA which isn’t ideal but seems to work perfectly well.

The scoop is rotated by a pair of gears that were initially driven by a N20 with a T shaped gearbox, but every one of these I tried proved to be both very slow and very low torque so the chassis was redesigned to hold an N20 mounted transversely that drives a D shaped 3mm countershaft between the gears on either side. So far this has proved very effective, though there have been some issues keeping the motor in place in the new design (shown here with some battle damage courtesy of Dissector - which fortunately missed anything vital).

Big Loader has proved remarkably effective at twisting loose from grabby opponents, but has a weakness against spinners due to the thin and brittle FR4 parts and 3D printed scoop. I’ve recently been testing a TPU version of the scoop to try and avoid this.

The main remaining issue with Big Loader has been getting the scoop to stop rotating when using a standard radio, since it’s driven by an N20 with no endstops. This has led to a few embarassing defeats including rotating its way out of the arena before I could stop it at AWS 67!

Recently I’ve moved from using a Hitec Aurora 9 radio with a radio module to one converted from a cheap drone transmitter. One of the surprising benefits of the no-name radio is that it has a pair of shoulder buttons. Programming these so the throttle stick does nothing until a shoulder button is pressed, with the left shoulder button also reversing the throttle output, provides a way to drive the rotation with full control of the speed but the ability to instantly and reliably centre the stick hugely improved Big Loader’s performance at SCAR 6 (though it was hampered with various other technical issues) so I’m looking forwards to seeing how this works at the next event.

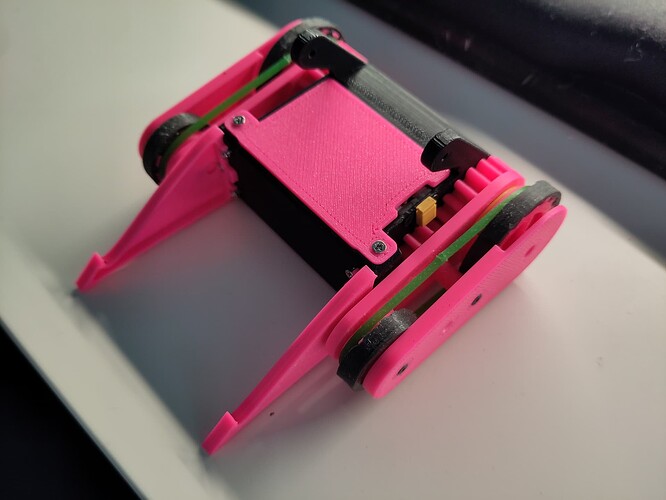

Mlemp

Mlemp is my newest antweight, and it evolved from a 4 wheel drive chassis I threw together and printed in a hurry as a loaner bot for Nottingham Hackspace’s Hacktvate tournament last year (under the name Cardinal, because of its redness). I printed it in TPU on a whim which has proven useful and it’s possible that in addition to being robust the squishyness helps traction by keeping all 4 wheels on the ground. Unfortunately since this was thrown together in a hurry it doesn’t use my usual antweight link PCB and instead I ran it with a pin header sticking out of the back which proved to be its downfall.

After Hacktivate I realised that the screws that attach the top and bottom parts of the robot would make a great mounting point for attachments, so with SCAR 6 coming up and the 4" cube restrictuon going out of the window I printed a variety of tongues out of some Mylar sheet I had lying around. The tongue attachments hopefully explain the name of the robot. ![]()

The first attachment was inspired by a certain robot named after the 4" cube rule, and is named the Hoop of Shame, though its effectiveness is probably very situational.

The second attachment I’ve tried out so far is just a giant scoop made from an A5 sheet of Mylar. With this attachment I was able to bully a vertical bar spinner around the arena for all but 3 seconds of the fight (when I fed my own wheel into his spinner and had my link sniped shortly after), though it didn’t fare so well against face spinner Danger Cone which was able to grab the sheet of Mylar just so, yeeting Mlemp from the arena.

Since then I’ve built up an embarassingly large collection of experimental tongue attachments, which I’m hoping to test out at upcoming events (at least ones where they’re legal to use) and am currently printing a revised version of the chassis which puts the link somewhere safely out of the way and should close up better than the current version.

That brings me roughly up to date with antweight shenanigans. ![]()