Jack Brotherhood - now on Spotify

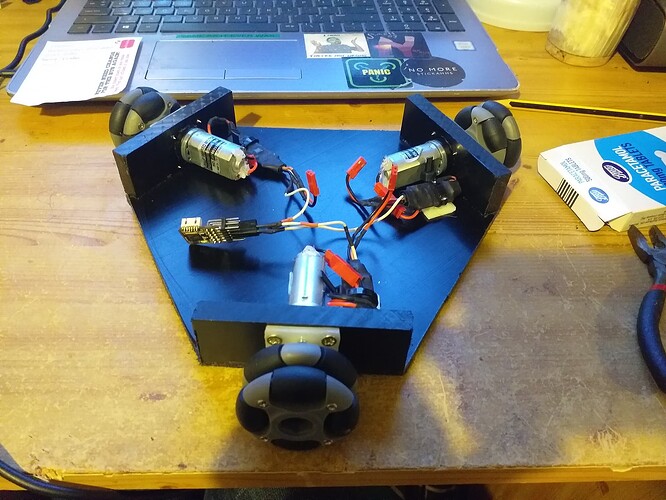

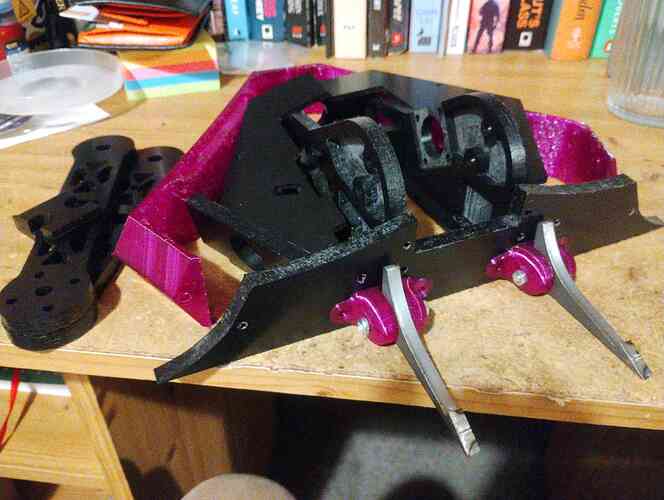

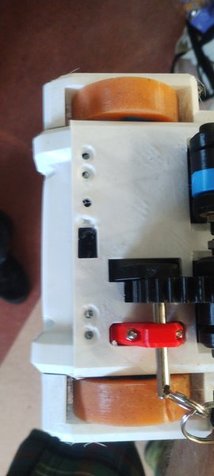

In the wake of Sceetles, I took a little time to reduce the weight yet further. The tapered edges of the front wedge had become curled up, so I chopped them off, removed the remains of the arm spacer, and printed the Aluminium Fingertech Mount plate in PLA-ST. The wheels, too, were reprinted in PLA-ST for added durability. They are always going to be more vulnerable than regular wheels, but I was interested to see how the filament would perform. I finally had enough weight for the heavy blade.

I also had time for more testing, both in my antweight arena, and in Jamie Mcharg’s workshop. Footage below:

https://fb.watch/xnd0dXmnCT/

I had a great time taking chunks out of the old Salvager and Flatulence chassis, and smashing up a DVD player with a featherweight. More importantly, after some careful loctite application, and great care not to overtighten the grub screw, it seemed like Surgeon could finally self-right, at least on a full charge. I felt happy, and prepared for MiniBeasts in the East. Thanks to Jamie for having me over!

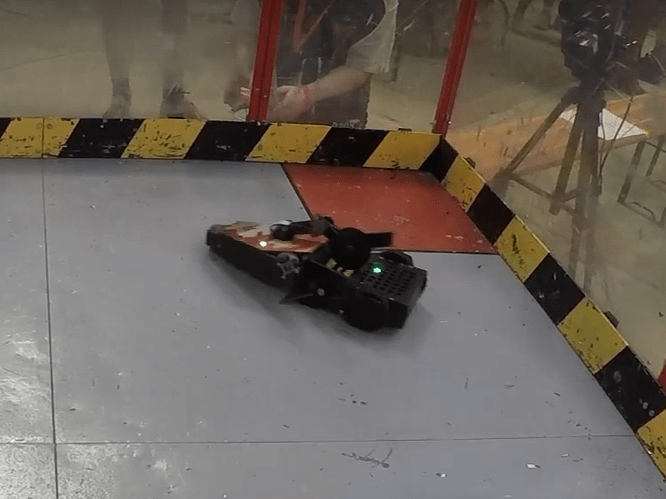

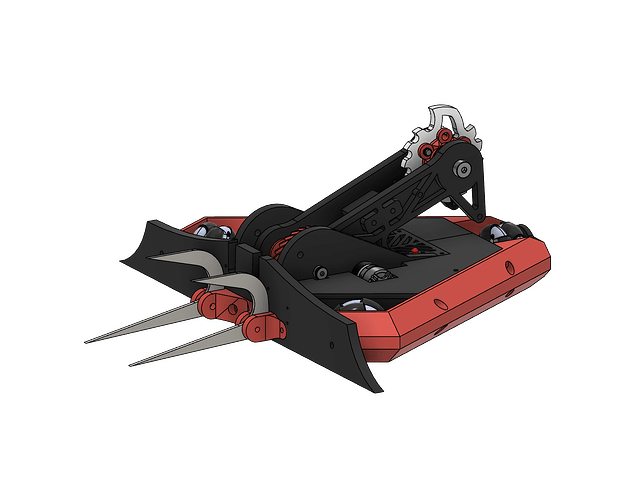

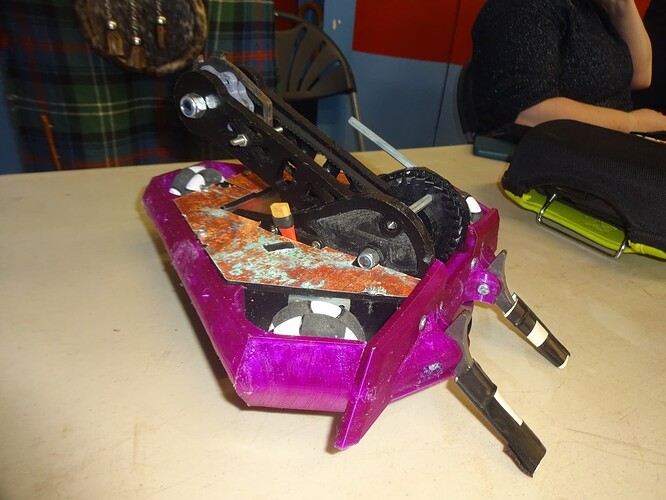

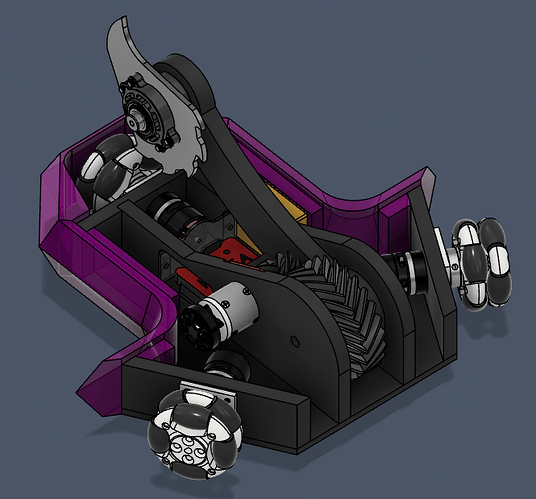

Those Dutch Angles again. Barber Surgeon is just a 60s Batman Villain.

Look, Simba: Everything the light touches is our kingdom.

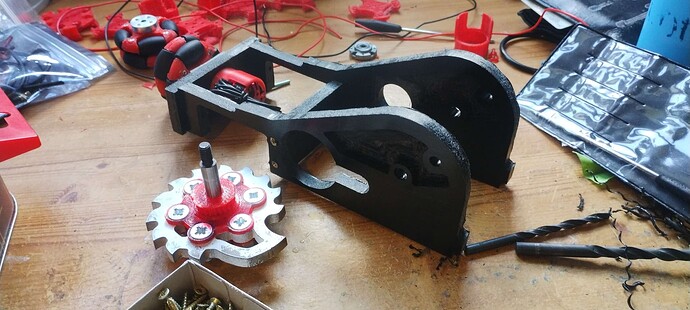

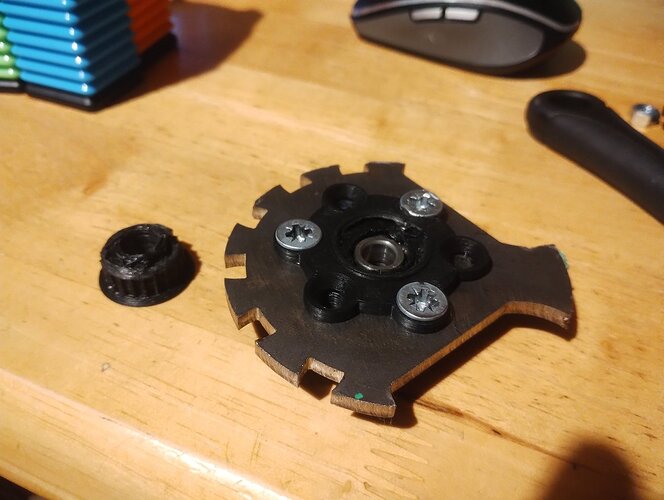

I did actually break a hub. I forget what this was printed from - probably PLA. New hubs were 100% infill PLA-ST.

My home testing proved the weapon could now punch through 3mm UHMW.

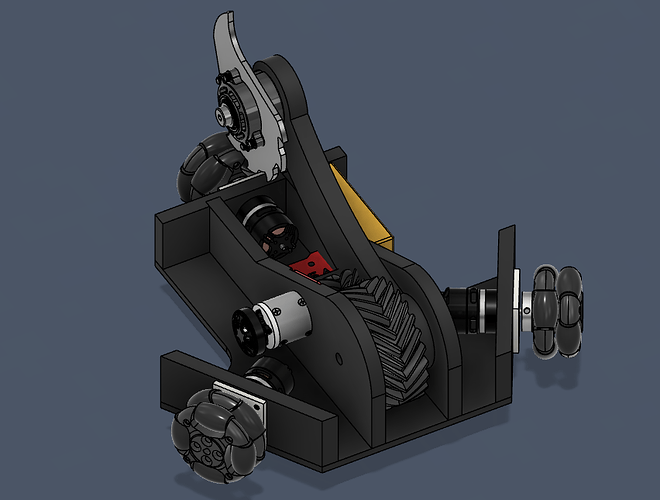

The MITE-y Quinn

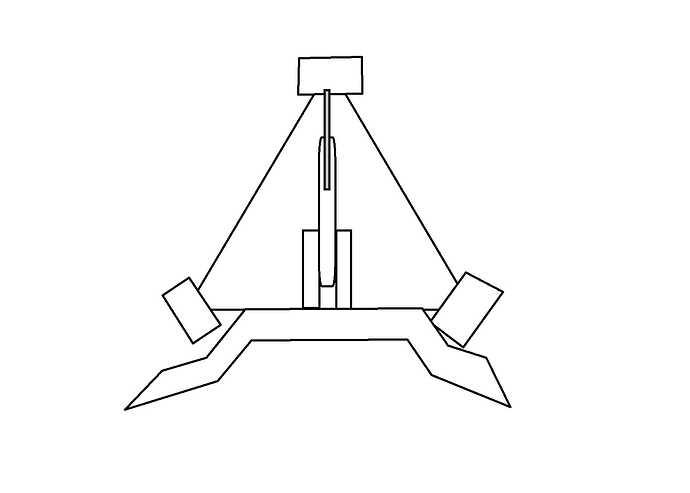

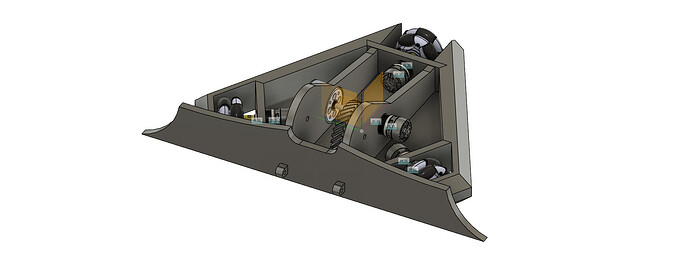

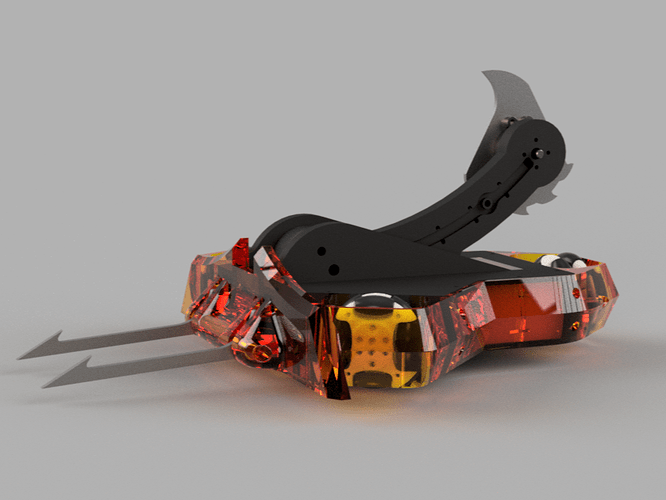

And so it was down to Norwich for the inaugural MITE event, looking fresh with new stickers and the heavy disc. It had been designed before Barber Surgeon 2, intended as a reversible asymmetric weapon, allowing a ‘vert mode’ or for tooth wear on both sides of the disc. In reality, the rear ‘teeth’ were never going to do anything, but do look cool, like a gear. I thought it looked a bit like a bunch of flowers, so called it ‘The Posie’, to keep with the medieval medical theme.

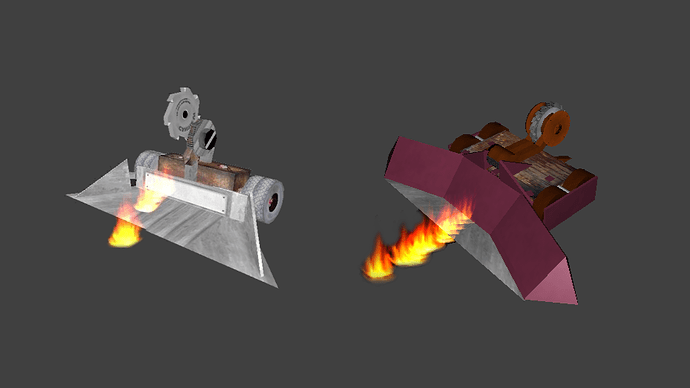

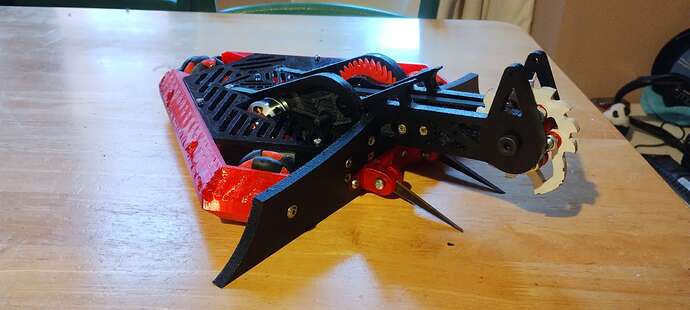

Hot. Also new stickers. Very proud of how they came out. Note the amount of fork flop. This will be very important later.

My first matchup was against Gremlin Bait, a billet aluminium wedgebot, driven by Morgan’s partner, Faith. Never underestimate your opponent, but it seemed like a nice, non-damaging way to start the day, though I probably wasn’t going to be puncturing any Lipos.

Wait for a good hit. I was a bit jumpy early on.

It was initially a cagey match, and Gremlin bait did well to slip away from any meaningful hits, and did manage a good drive on the wedge. At one point the arm seemed not to return to it’s firing position, but I was ultimately able to reset it.

Then the fight changed, and Surgeon was able to strafe to the side of Gremlin Bait, and catch it on the forks. Four hits followed in quick succession, removing a wheel, pushing it under my opponent, driving it to the wall, and managing a perfect link snipe, bisecting the connector wire in two, right down the centre. Barber Surgeon got it’s first tournament win, and by KO, too, the heavy weapon coming in clutch!

Something something don’t bring wheels into the arena. Omni Wheel supremacy.

The Aftermath. Surgeon’s best performance to date.

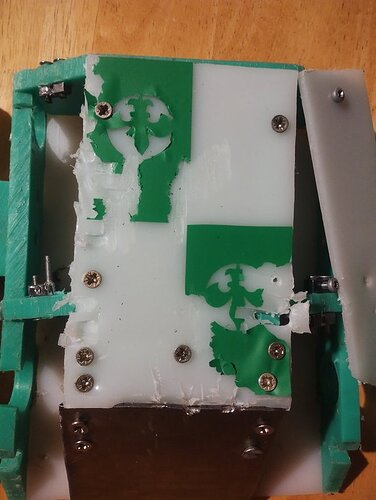

I had hoped this would set the tone for the rest of the day. Sadly, it did not. My second match was against Will Thomas’ Inversion, and it did exactly that, and pretty quickly, too. Despite self-righting in the tests, Barber got stage fright under the lights, on the grippy arena floor, and stayed face down. Will played with his food a little, but the match was basically over. Even in testing after the event, I was never able to replicate that one self-right test at Jamie’s. Fight three was much of the same, in a rumble against CDG and Sniper. I fitted the TPU duck-bill wedge, but Sniper’s narrow blade grabbed into the UHMW front plough and overturned us, and that was that.

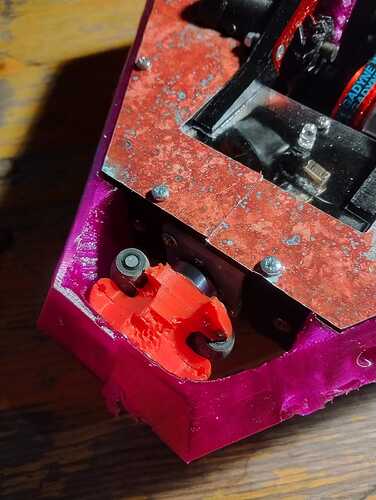

Kinda sums up the rest of the event. You can also see a heat nut poking out near the front wheel. The few that were left in the design were a reoccurring bane.

Nevrtheless, MITE was a ton of fun for that first fight alone. As I said before, the robot did what it was designed to do, which is always my yardstick for satisfaction, rather than tournament success. The self-righting, though, was a puzzle. The TPU gear seemed to be bending and skipping against the nylon pinion. So a thicker gear or higher MOD value seemed to be the solution. But could that be right? EVA-02 has a very small MOD value and still self-rights fine. As it happened, the centre distance between the existing gears made designing for anything else quite a challenge, and my ultimate solution was to trial an all nylon geartrain.

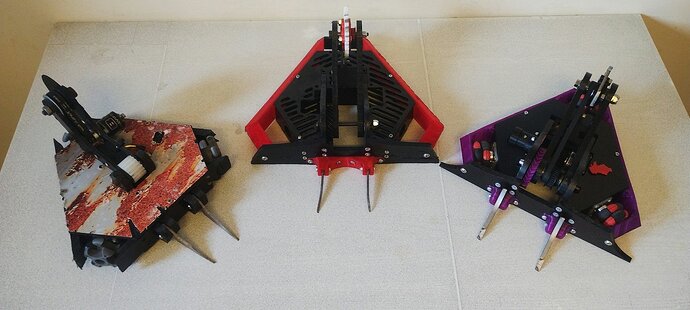

I also wanted to design some ‘proper’ weapons, as I still felt that I could be doing more damage. My efforts so far had been either copies of existing designs that weren’t optimised for this application, or my own fumbling first attempts. Under Sion’s supervision, I created some new discs in preparation for Rapture, giving me quite the set of Surgeon’s tools to choose from.

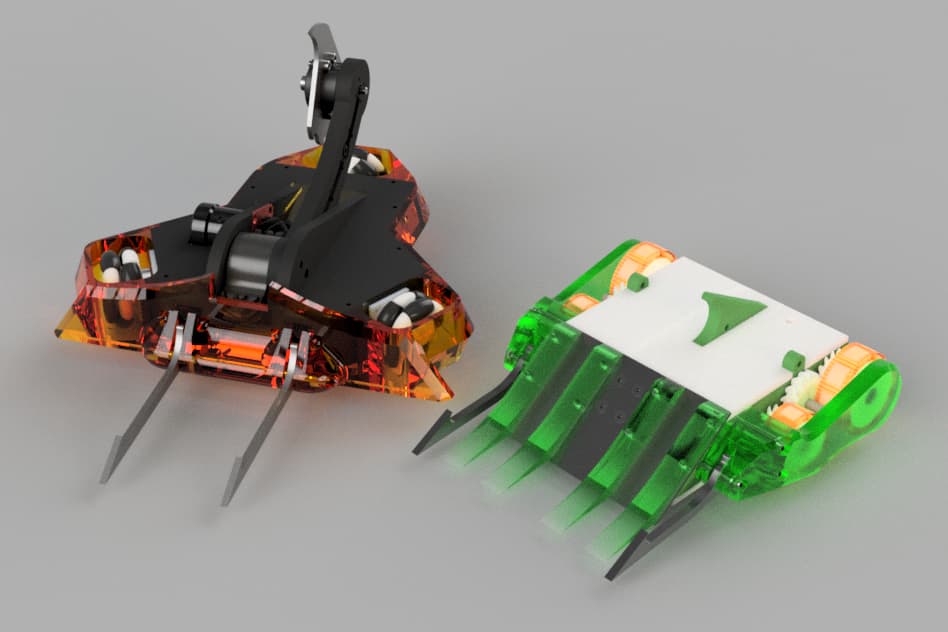

Tools of the trade.

From left to right, including the weight of the hub, screws and bearing:

- The Heretic’s Spike - 76g. Nice and light with a big bite!

- The Sawtooth - 76g. The new standard setup, designed to rip and tear.

- The Scythe - 85g. An 8mm hardox axe head for sportsman matches or to feed into overhead weapons.

- The Posie - 124g. The signature look, heavy, packs a punch.

I also replaced the UHMW plough for a TPU one that keyed into all of the weird chassis angles. I had been impressed with how the material had held up as side armour, even as a lighter print, and was keen to try it our for myself as a plough, ready to commit to a full wraparound TPU armour ring.

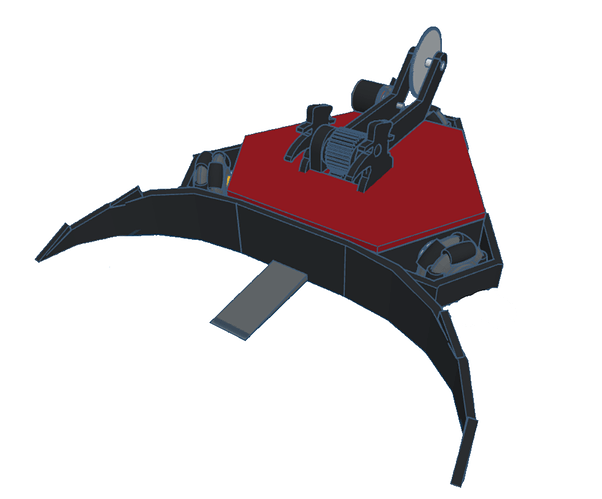

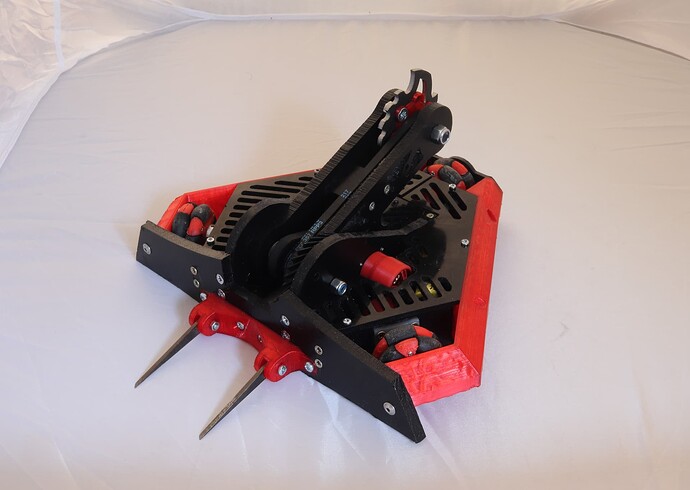

Barber Surgeon the night before Rapture Gaming Festival. I wouldn’t collect the nylon gears until the day of the event.

Travellers Beware: Here Be Spoliers:

I realise some people on this site have omitted a Rapture report from their recaps. I am going to cover the event for the following reasons:

- Robot Rebellion have said that it is ok to do so.

- This forum is directed at the robot building community, not the fan audience - so I kinda assume that you were there or knew someone who was.

- You have freedom to avoid spoilers if you wish - just come back later.

- The event marked a significant breakthrough in Barber Surg3on’s development.

That said, without footage or photos, this will be a brief recap that may well be revisited at a later date. Or not.

Propane. Yikes.

Match one was against Critical Fail, a Thagomiser-inspired first bot for it’s builder. The weapon, a fingertech bar, directly mounted to an antweight brushless motor, exploded on first contact with my forks. But the 10mm top armour was inpenetrable, and after an unstick, I went for the wheels. But I got greedy, seeing an opportunity to pit my opponent, who escaped just in time for me to sail into the pit myself. 0-1.

Match two was against heat seed EMP. With the nylon gear untested but installed, I hoped to repeat my previous self-righting successes, however, it was not to be. I landed a small shot to Felix’s flipping arm, but he had me over in a flash, and Barber would, yet again, remain face down. EMP capitalised quickly, ejecting me from the arena. 0-2.

Lastly was Propane. With my new drum forks fitted, I still did my best to avoid the devastating eggbeater of the flywheel robot. I almost had an opportunity, too - Propane got hung up on the pit, and I was perfectly lined up to hit his printed lid right above the battery - unfortunately, in the half second the arm takes to fire, Propane went from stuck to freed, and escaped. It quickly launched a counter attack, and I was flipped. 0-3.

Day two was all about fun and fact-finding. The suggestion came from Ryan Bratley, that even Surgeon’s comparatively shorter forks might be too much of a fulcrum point for my setup to handle. On the Sunday morning I borrowed an angle grinder from Dave Weston, and on my messiest set of forks, cut off the lugs that prevent them from flopping all the way down, to test this theory, and see if it could self right. I’d fitted the TPU gear first, since I knew a nylon/TPU pairing was a proven material setup by others.

Before I could get to the test box, however, I found myself in a non-spinner rumble, using the Scythe. Did it self right? No. Afterwards, I swapped to the nylon gear and put it in the test box. Did it self right now? Yes! I had another rumble, for a side event that I won’t spoil where I wasn’t flipped, but came runner up, due to an overtightened weapon bolt when changing setups.

My final match of the weekend started as a few spinners going in against Comoran, but turned into THE spinner rumble of the weekend. Propane, Zephyrus, Icebreaker, Unstoppable Force, Baby Dead Bod, Paradigm Spin, Comoran, and me… Ouch! Unstoppable Force boxrushed me immediately and flipped me. And I self-righted! I strafed over to Icebreaker, removing some of it’s TPU armour, before it yeeted me across the box, landing upside down. And I self-righted! Propane corralled me into a corner, toppling me over… And I self-righted! Five times in total, lasting until the end of the fight, coming second to Propane. Granted, there were a few issues getting off of my forks, but I left Rapture buoyed by a problem solved, despite my main tournament run.

A collage of grainy phone shots - Critical Fail’s bait-and-switch, EMP’s OOTA, the Scythe’s debut fight, Propane’s escape, and Barber’s successful self-righting!

In the months after Rapture, though, robots dropped off my priorities list as life took over. for Battle in the Burgh, my local event, I simply modified some more old forks, (as no group metal orders were forthcoming) and hand some new PLA-ST wheel cores printed on Sion’s incredible Bambu printer.