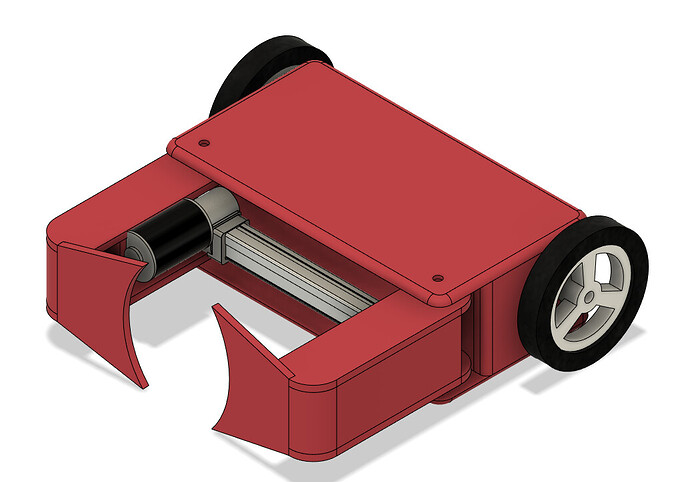

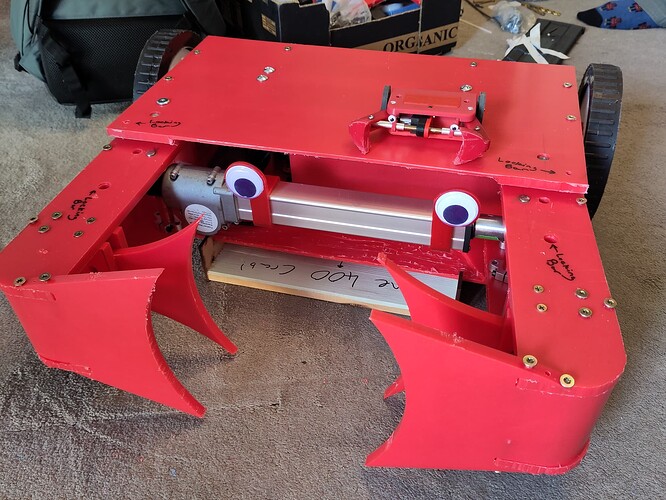

Time 400 Crab got a few upgrades ahead of RoboDojo’s December Sportsman Feathers event.

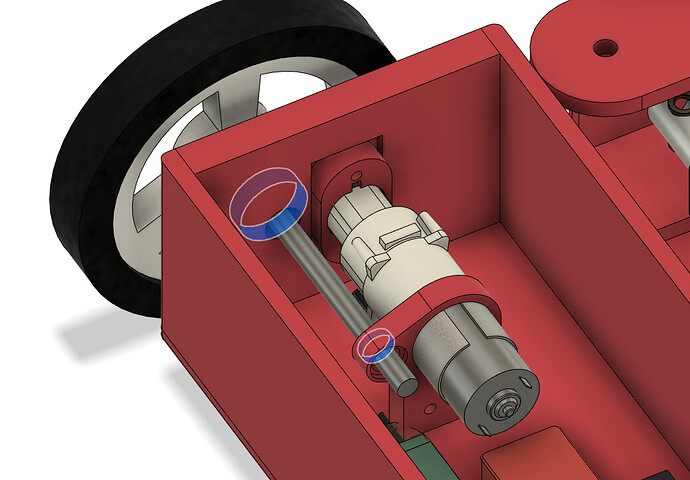

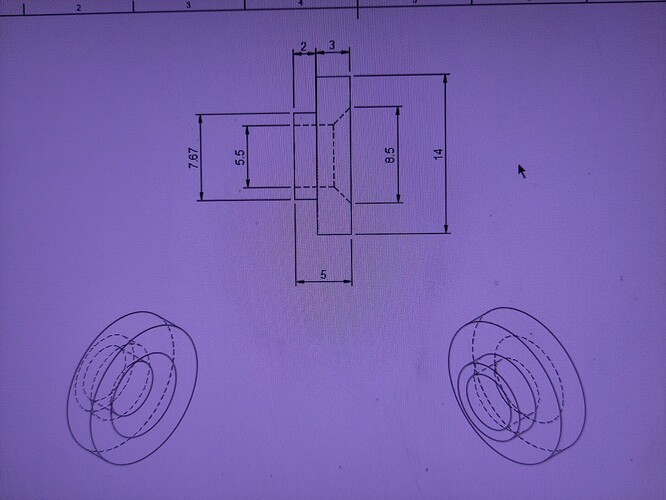

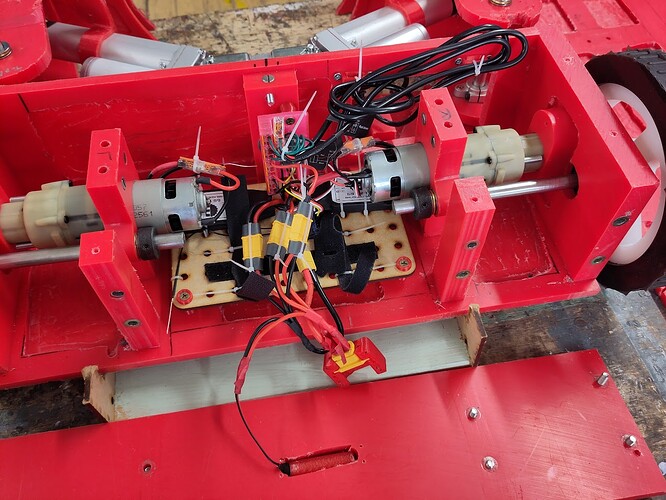

The most important change I made was to strip down the drive motors, properly clean everything and loctite the drive gears on. I forgot to photograph them but I also designed and turned some washers to back up the M5 left hand lockscrews, since these had a habit of deforming or completely breaking the washers I had been using.

These have a small shoulder that fits inside the gear (since the gears are longer than the motor shaft) then a 3mm thick section with a countersink so the screw is well fully in contact and there’s plenty of material to back it up.

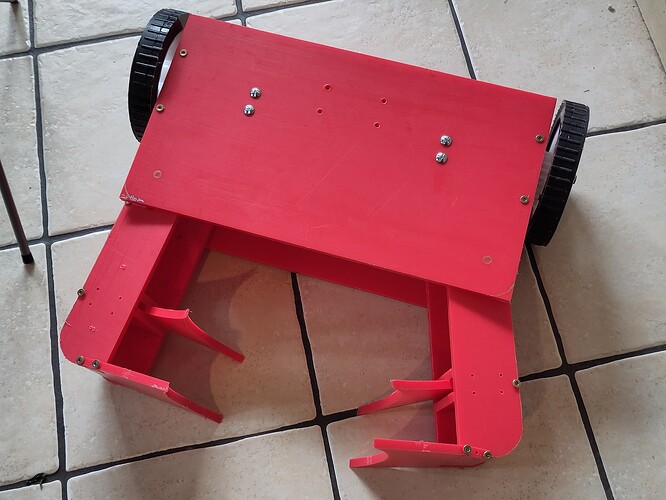

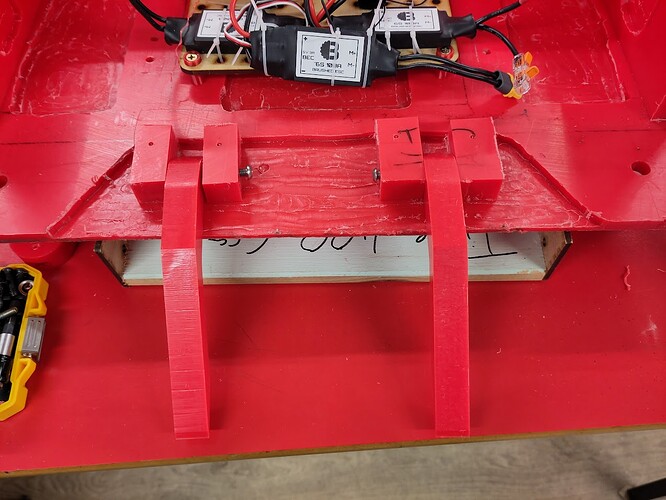

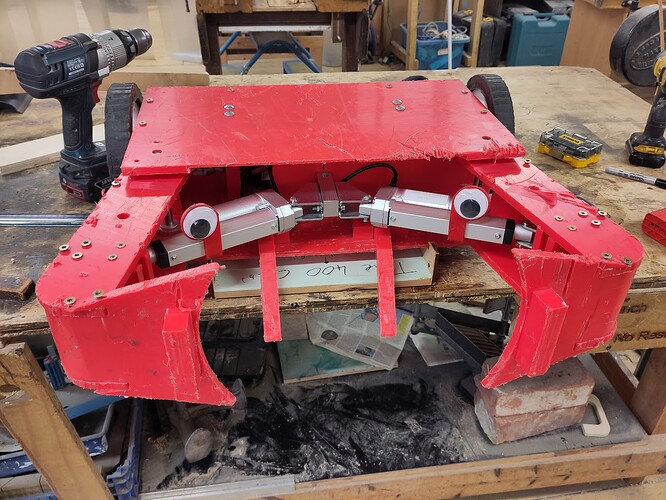

I also machined some forks (pedipalps?) since my crab designs are very anti-ground game which tends to cause the robot I’m trying to grab to go underneath instead.

These don’t stick out very far but hopefully will do the job when the claws are open.

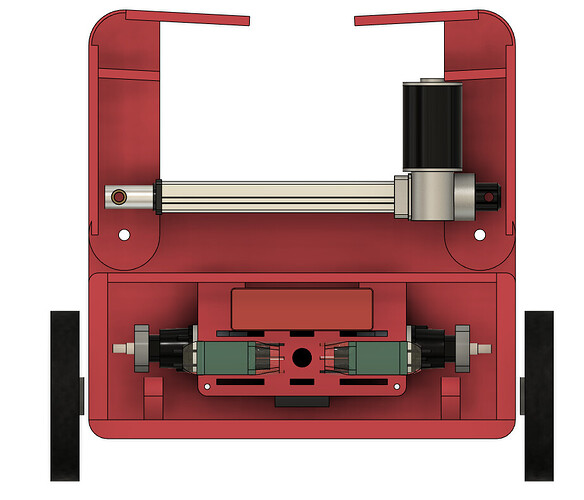

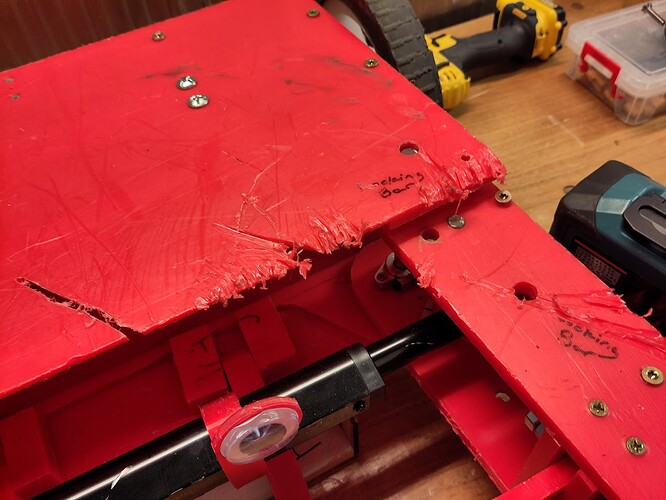

I also replaced the ‘stub’ spindles that the claw pivots on with full height 12mm steel bar. These were trimmed to save weight and because I didn’t have enough continuous bar when I built them, but they were allowing the claws to go over centre causing the crab to get stuck in ‘crab dab’ pose. This seemed to help a little bit, but there’s still a dabbing problem that’s going to require some more geometry adjustments to fix.

I’m tempted to replace the single linac with a pair of shorter ones and a mixer setup so I can have full control of the claws at some point in the future.

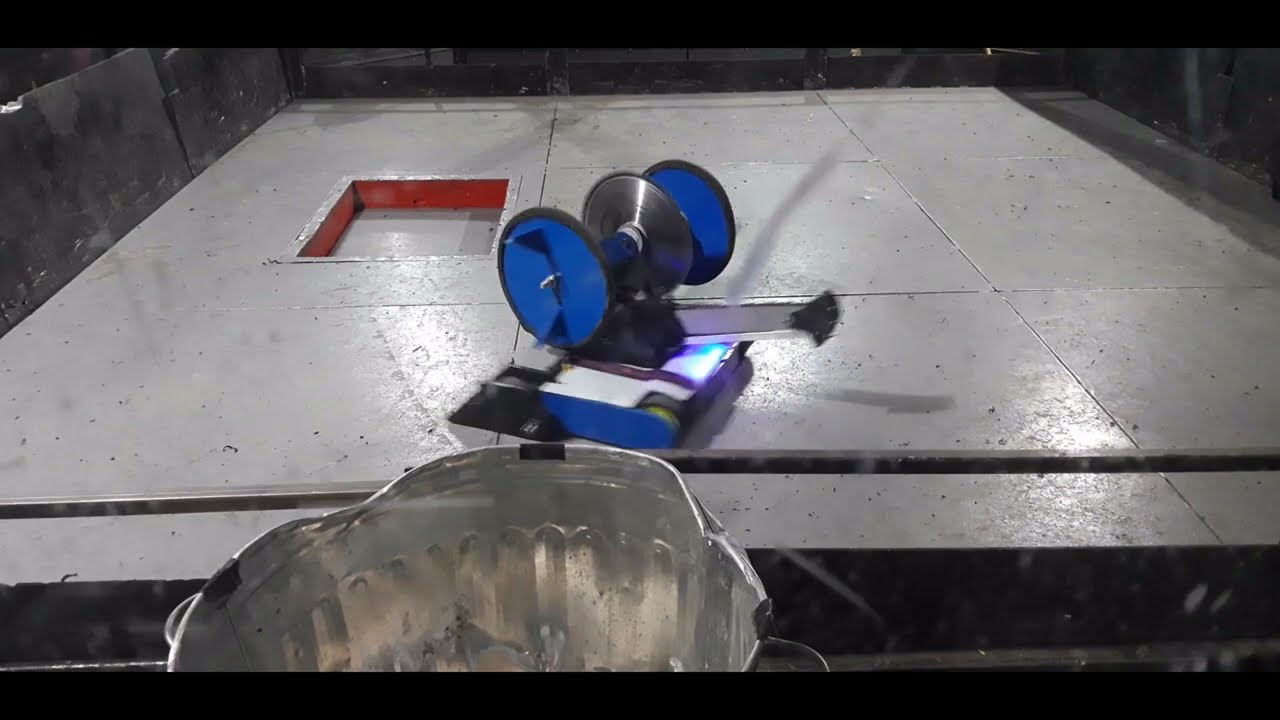

The first fight of the day was against Killionaire Shortbread driven by Simon, which was standing in for Team Earl Grey bot. Team Earl Grey was unfortunately out of action due to complications stemming from forgetting to bring their transmitters and ending in a blow ESC.

The pit was also out of action at this point so this fight had an arena-side dropout instead.

The forks/palps seemed to do a good job of preventing Killionairre from getting under me, but I was still having a hard time getting a grab on it, partly due to crab-dab syndrome.

The fight was unfortunately cut short when a motor that had likely been damaged at the previous event decided to burn out and Crab started emitting nasty enamel smoke, leading to a KO win for Killionairre.

Fortunately the loctite on the gear had held so after giving her some time to cool off I just swapped out the (probably) dead motor leaving the gearbox in place. I’m regretting not doing this before the fight, but I’d lost track of which motor had issues last time by the time I got home.

Crab’s second fight was against Bread Dead Redemption and I settled for a strategy of trying not to get flipped out of the arena and hoping to get around the side and attempt a grab.

I managed to get an early push in, but BDR was able to flip me near the side of the arena, leading to some hairy moments where I was trying to stay right side if possible and drive away from the arena side at whichever points the wheels were on the ground.

Fortunately I managed to get away from the arena edge and settled on a strategy of jamming a claw under BDR’s flipper where possible to keep some control of the fight. Unfortunately due to the crab-dab issue I was never able to manouver from this position to a place where I could also grab the side of BDR so we had a bit of a stalemate until the pit opened.

Once the pit was open BDR managed to push crab over it from the back but I was able to reverse away before the pit was fully open.

The second time I didn’t get quite so lucky and was left with a wheel hovering over the pit and my attempt to escape wasn’t so successful with the right wheel eventually dropping in.

This was a fun driving match and a well deserved win for Bread Dead Redemption.

Fight 3 was against Sam’s robot Captain Kathryn Chainway which is both very wide and also fearsome when its chainsaw is working.

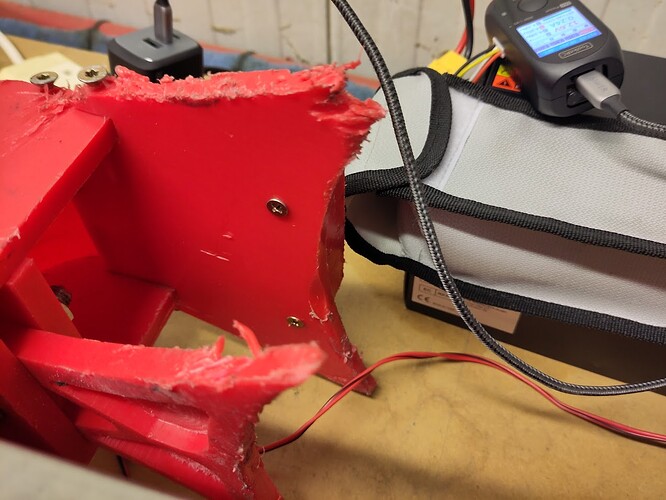

The first engagement was face on, allowing the chainsaw to give Crab a fringe, but this was fortunately limited to cosmetic damage.

After various face on engagements and getting stuck on top of Chainway for a bit I managed to open the pit and push Chainway in from behind for Crab’s first win of the day.

Fight 4 was against Danger UXB which is a thwackbot and an awkward shape to get a grip on.

I did at one point manage to grab it width wise and pull it backwards across the arena, so it’s nice to see the claws doing what they’re supposed to occasionally.

Once the pit was open I was eventually able to push Danger UXB away from the arena edge and into the pit, albeit with some risky manouvering in the area behind the pit.

This left Crab in a playoff for 6th or 7th place against Bob 4.

Bob is a vaguelly square shaped axe bot so should be an ideal shape for gripping with crab claws, though I still had a hard time making this happen due to the dabbing issues.

After a couple of close calls and an extended pushing match I was able to pit Bob, leaving Crab in 6th place.

I’m pleased with this result, especially after the rough start and the event was great fun with lots of great fights.

After 5 fights the loctite on the drive gears had held, so I’m glad I don’t need to immediately follow through on a brushless upgrade for the sake of a better mounting system, and it seems like the current motors held up. At risk of setting myself up for failure I’m hoping this means the next event will be free of motor trouble and Crab should be at peak performance.

Generally the other tweaks did a good job, though I don’t feel like the forks got very well tested (I would have liked to see if they help against Malachite).

I’ve got a bit more work to do on resolving the crab-dab issue. I’m not sure yet whether this will take the form of geometry changes to the existing grabber plus maybe a centering spring or damping, or a rework to use two separate actuators.

![]()