Hello fine people of BBB!

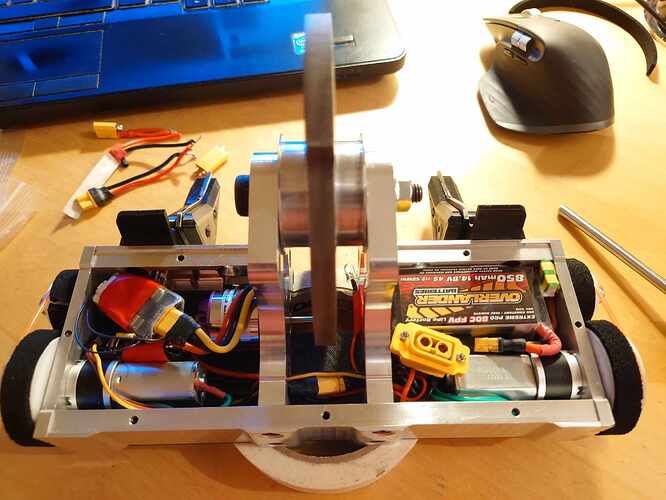

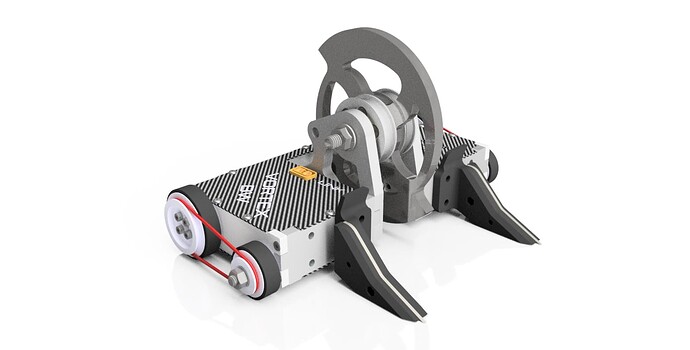

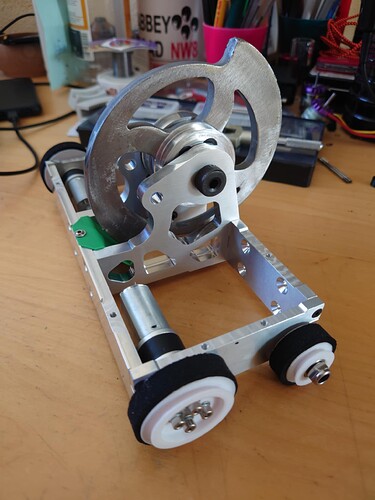

Burgh has come and gone and overall, as a first beetle, I’m very pleased with Vortex BW. It does its thing

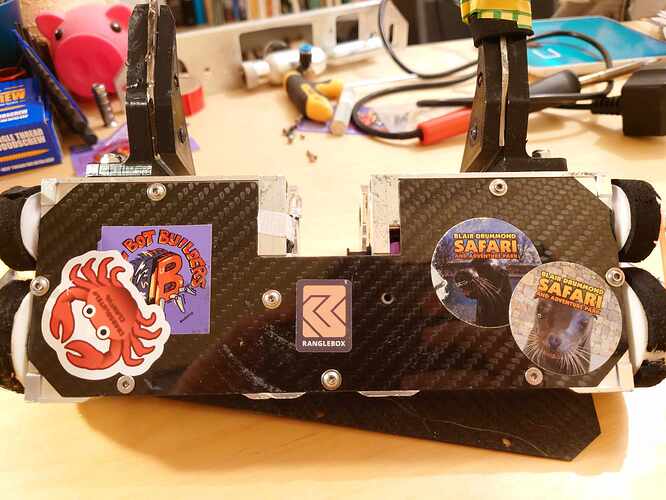

We all love a bit of merch don’t we?

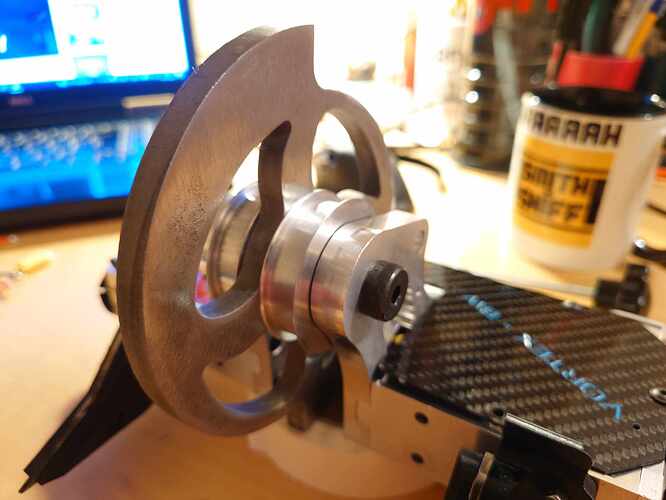

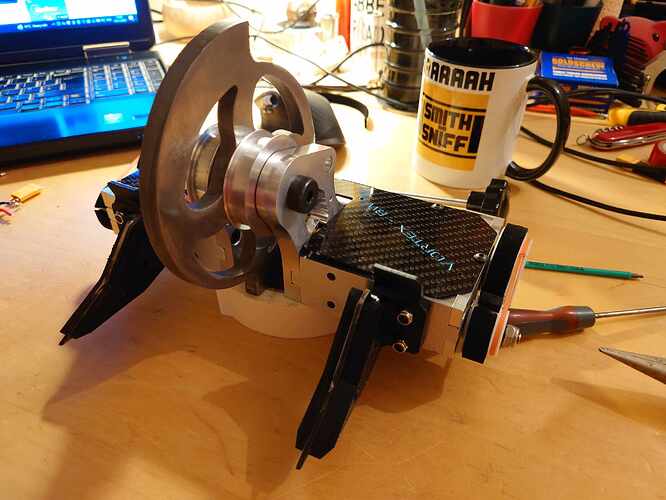

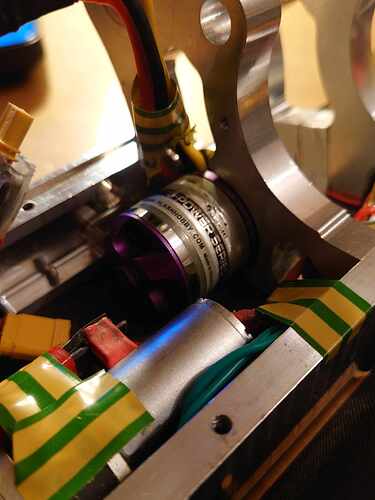

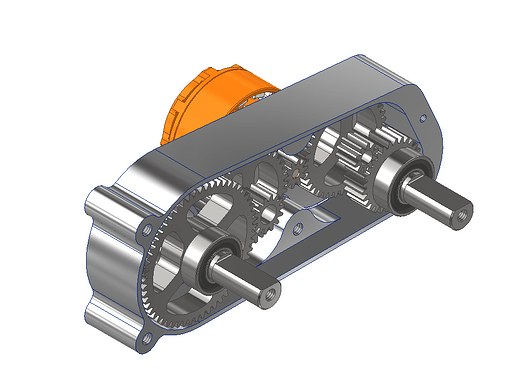

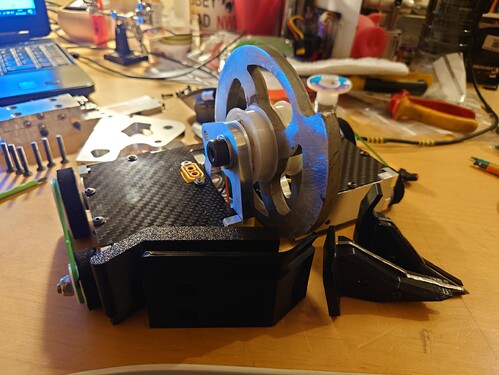

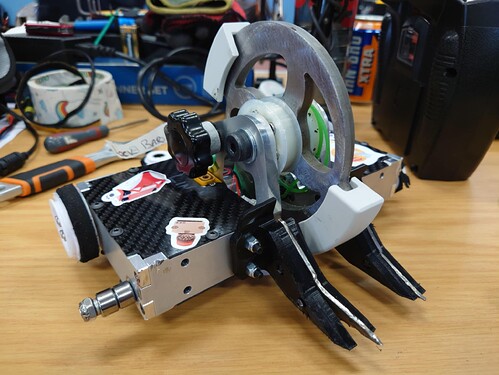

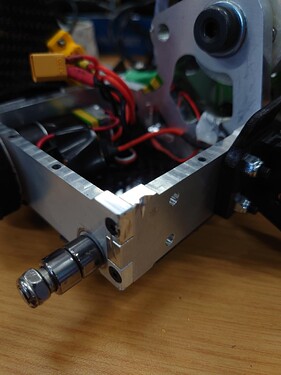

The first hurdle at the event was getting through tech checks, I don’t (yet…) have anywhere to test Vortex’s weapon so whilst I knew it’d twitch and the motor had detected fine I hadn’t spun anything heavy since Subterranean. When we plonked the lil dude in the test box it would do maybe 20 revolutions before everything locked solid. Bugger. I traced that fault, eventually, to some bronze shim washers I’d put between the disc pulleys and bulkheads to act as thrust washers. These would, instead, just start chewing into the ali frame and gall everything up. I disposed of them and just accepted I’d have a bit of end float on the weapon, and after that it spun up well.

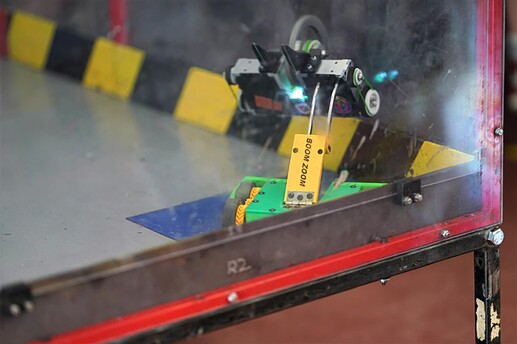

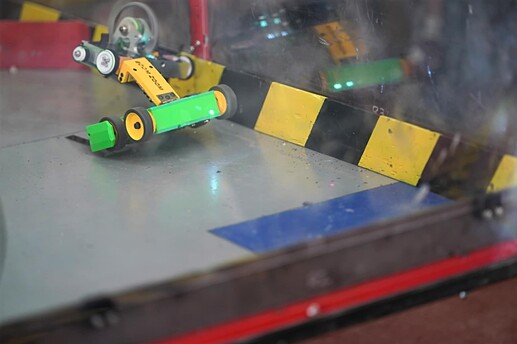

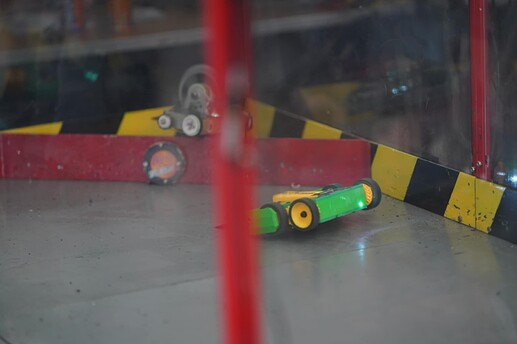

My draw was relatively kind, no Slice or Shrekt! The first fight was BoomZoom, who went on to get 2nd place. BoomZoom is quick but I got some good hits on him, bent his lifter arm and chewed up the front end. However, Rob’s superior driving resulted in me getting pitted. 0-1

Fight 2 was a rematch from Sub against SadBoi, except this time I’d have a weapon! Tom was very pleased with the Hardox Extreme front plate on SadBoi, and it was worrysome to me. SadBoi bullied me around a bit, slammed me into some sad places but eventually I got a good clock on his front plate and ripped the whole thing right off! SadBoi opened the pit and I got half stuck on it, however with SadBoi being now well under 1kg I could lob him from end-to-end of the arena every time he tried to push me down. Sadly, however, gravity was not on my side and eventually I ended up pitted again. 0-2

Very SadBoi…

A slightly dull disc tooth from eating Hardox extreme

Comparison of a healthier tooth (not fully healthy mind)

Fight 3 was against The Wider One 2, a huge spinner to contrast my dinky one. Alys had a gameplan here, go for my wheels and it was working pretty well for a bit. I managed to get some hits on their frame and took off a wing from them, then after a particularly big hit Wider One stopped. The linkblock was loose on Wider One and they were counted out for Vortex’s (and my) first ever KO win  thank you Alys, 1-2

thank you Alys, 1-2

1 Wider One wing is wider than my entire bot, they ain’t joking when they say it’s long

Bent fork prongs were the only real damage from day 1, an easy swap

1-2 from fight night was not enough to hit the top 16 sadly, however I was very happy with how Vortex was performing. It had run reliably, dished out some big hits and not taken any major damage so I left after day 1 feeling pretty pleased.

Day 2, photography taking place where testing should go…

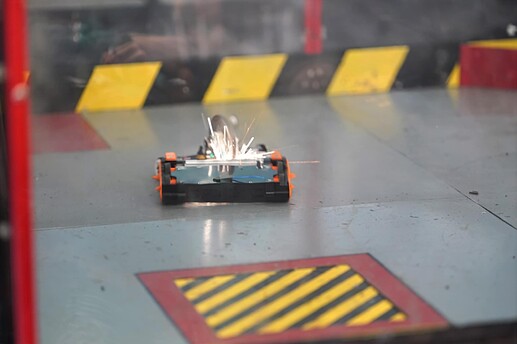

That translated into some complacency when I signed up for the doubles tournament the next day with Mark Smith’s Kreigmeister. What I should have done was a nice early systems test to make sure everything was okay for day 2, but I didn’t. Hence when the box was locked and the fight started Vortex simply refused to spin. One hit from Yam and I was upside down and out, leaving Mark in a 2v1.

I feel I let Mark down there as I think with both of us working we could have had that fight, so apologies to him and a hard lesson learned for the future. The weapon motor had bound up, however reversing it caused it to free up and it has not caused any problems since. I think the weapon motor must have ingested something, but what that was we’ll never know. I might strip the motor right down over winter and see if there’s any damage to it that could explain, maybe a shattered/cracked magnet?

Really picked its moment to decide to be a diva

My final fight was a 4-way melee whiteboard, that was a good old-skool tussle. Vortex BW isn’t really designed for multi-bot stuff, it’s very directional in its attack and setup, but melees are fun! I was in with Belladrum, which is a nasty lil thing and it did manage to clip one of my wheels off. That was just the grub screw hub sliding off so not the end of the world, but it did show me how hard gyro driving is! I left one hell of a dent in Dave’s pit in this fight, apologies to his floor!

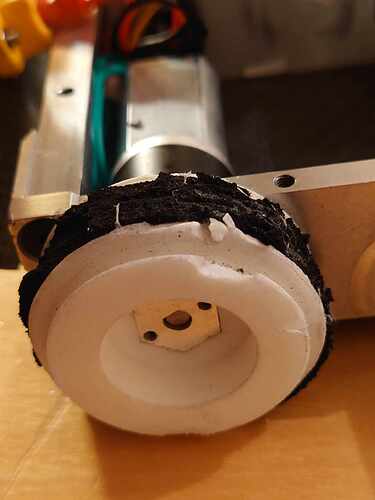

The offending wheel. I really must file in some notches to retain the grub screws next time!

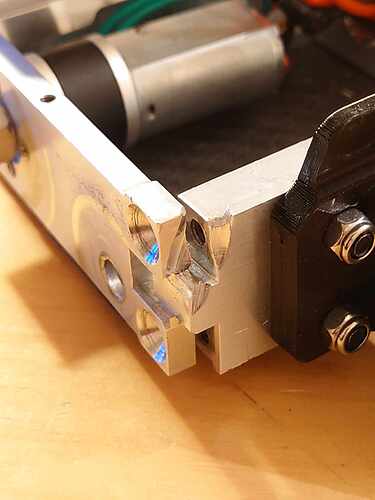

The only frame damage I took all weekend, from Belladrum I think(?). Only a nick really, the disc seemed to hit things before they hit me

So overall, I think Vortex BW had a good event! I went there to see if I had built a machine that was reliable and could deliver hits for 2 minutes. The answer to that is yes, it kept on ticking and the only thing that really let it down was me skimping on routine checks. The bot hits like a train and did some good damage, I’m very happy with taking SadBoi’s face off. And it won a fight!

However, there’s lots of things still to improve. A compiled list would be as below.

GOOD

- The weapon is reliable and hits damn, damn hard

- The drive was very responsive, and it’s a nippy so and so

- The frame is solid, probably too solid tbh. There is a slight tweak in it, as evidenced below but it was sent flying around and only took one nick

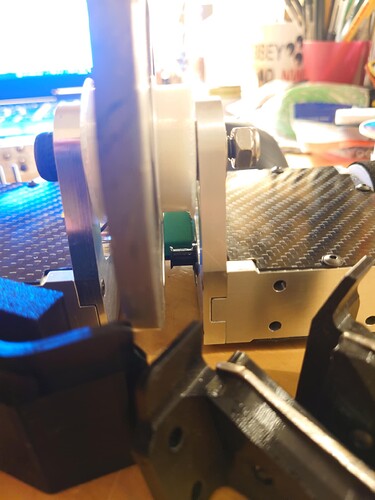

Not the most obvious to see, but there’s witness marks on one side of the pulley and not the other suggesting this wasn’t running straight and true by the end of the event

- The weapon reach lets you just go gung-ho into fights

- The EPDM “tyres” are pretty solid given they’re just adhesived on and they are fairly grippy as well as very easy to patch up and repair

Patched up, but still solid! PLA+ interiors with EPDM foam tyres, supergluing the ends of the foam was a good hack for keeping the tread on

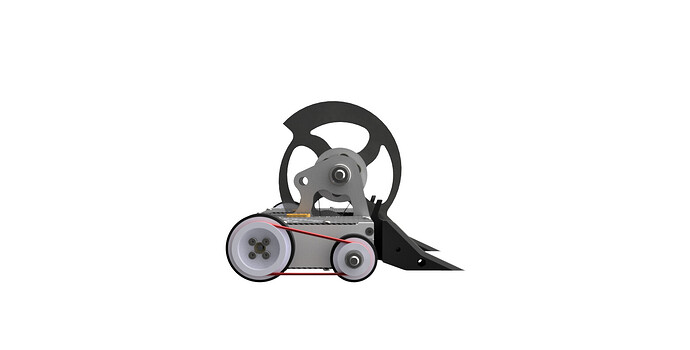

- TPU forks with a Ti inner look promising, but need more finessing

- The disc setup has enough power to spin up from standstill, whilst the bot is upside down. That means I can continue with weapon self righting

BAD

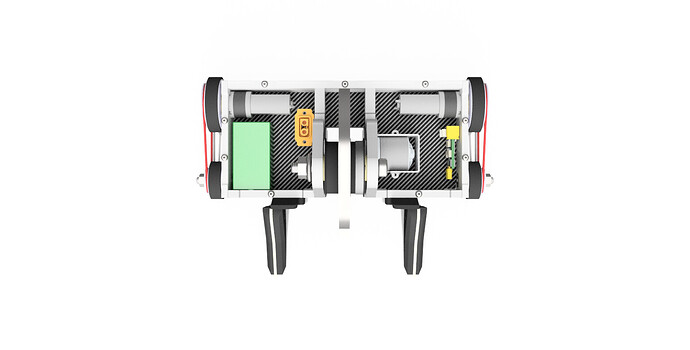

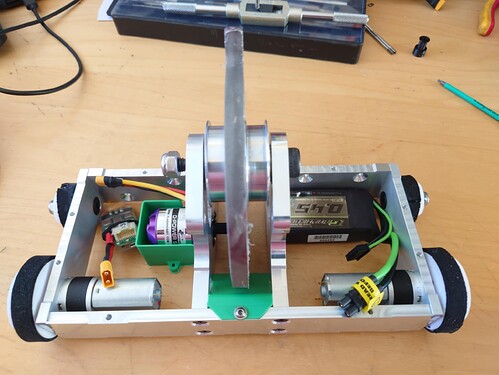

- There is no space inside the bot, so working on it is a pig. If it needs repairs then it’s a nightmare

Folks always seem surprised by the size of Vortex BW, Diet Coke for a sense of perspective

- The wheelbase is mega short, so it can easily have wheels lifted

- The weight distribution is a shambles, that goes hand-in-hand with above and needs sorting

- Top and bottom armour is very fragile. It’s survived 2 events, but 1mm carbon is just tempting fate…

The stickers of Oscar the Sea Lion did survive though, the thing I know everyone was worrying about

- Some bits of the chassis are defo too thick and could do with reducing in weight

- Some parts are a bit hefty too, such as the battery being a good 200mAh bigger than many others at Burgh

So a new Vortex BW will defo be getting designed over winter and debuted next year, exactly when I don’t know but its coming! It’ll still be 4WD, I like the idea of making something custom and funky. I also like the idea of playing with the track width front and rear, that could give the bot a cool look. I expected this version of the machine to be absolutely creamed at Burgh so I’m genuinely surprised it’s still running. I think I’ll keep it running for whiteboards etc

This is probs the last update for 2023, but the future looks bright for 2024. Thanks for following along, and I’ll be sure to keep this thread nice and updated with progress on V2 (actually V8 if you account for all the failed designs  ) as it comes together.

) as it comes together.

Much love