Hey all,

Finally took a stab at robots after just under a year, recently having been at Fightfest '24 with the ever-lovely Ellie Harrington. Wanted to duck-ument the process on building these guys.

![]() Lore

Lore![]()

So this kicks off last year, I can’t really remember the gist of it all but Ellie and I are looking at doing Makerfare over in France, and we’re like “Hey, lets make some raptors for it”. We have robots in the other weightclasses, should be nice to round out with full lineup.

I think the plan generally was “Robogames Deep 6 would be way funnier if there was two”. Kinda fit both our design philosophies! The idea was to have 2 robots with featherweight spec’d weapons and beetled drive and just generally be a big weapon delivery system.

![]() Design

Design![]()

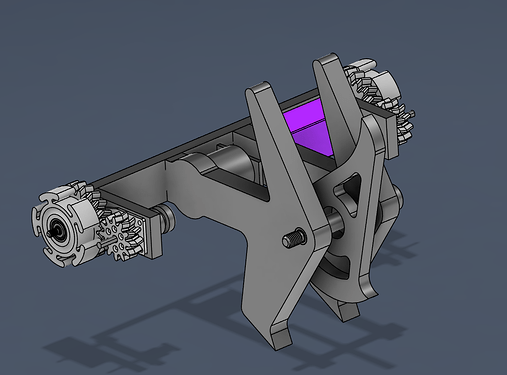

12lb over here presents a bit of a problem in that the weightclass doesn’t fucking exist. There was generally a lot of educated guesswork when designing this robot & we’re glad it all kinda worked. Settled on 12mm HDPE frame, with some 15mm weapon bulkheads. Felt like a good blend between Beetles & Feathers, which the weightclass falls into.

So like I mentioned earlier, initially we wanted featherweight waepons that move using beetle drive. Spoke to Filo early doors & he had just ran his 12lb at NHRL that year. We copied his recommendations at the time of a Repeat Max with some external gearing. Seemed pretty good, but we did explore some options like repeat ultras.

Super early mockup, trying to get the shaping right on it. Had picked out some components like the aforementioned drive, with 6S lipo & some stupid fucking inrunner which was dumb as fuck to mount.

Bit later on, ears and front feet become detachable for maintainability.

![]() Shuffler

Shuffler![]()

Focal point of the robot imo. I love shufflers, as many of you know. But this actually wasn’t my suggestion. Ellie thought we needed a weight bonus so fuck it. Shufflers.

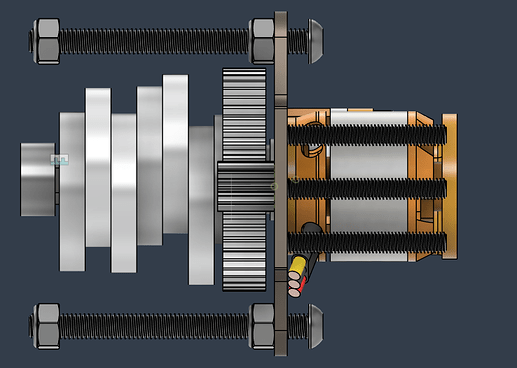

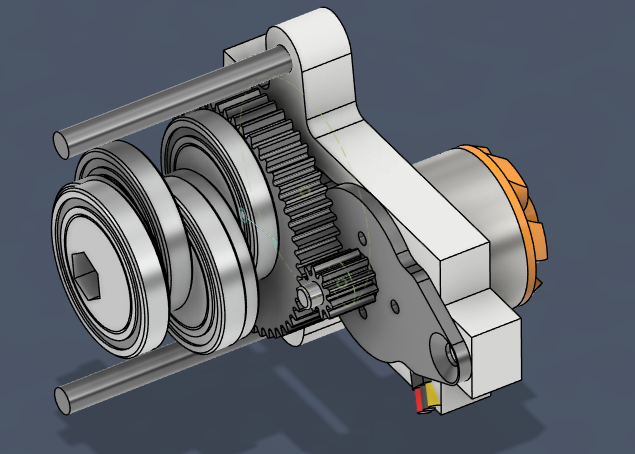

Here’s the first draft of it all. Back when we were gonna use Repeat Ultras. Basic idea is to have a bunch of Aluminium CAMs run the shaft. Rotated at 120 degrees with some bearings over the top, then legs.

Eventually we move over to some 750KV 3536 brushless outrunners, wanted more RPM on them, and shufflers dont really need that much torque, especially with this design. It’s a 5:1 gear ratio which gives us about 3K rpm on the final output shaft.

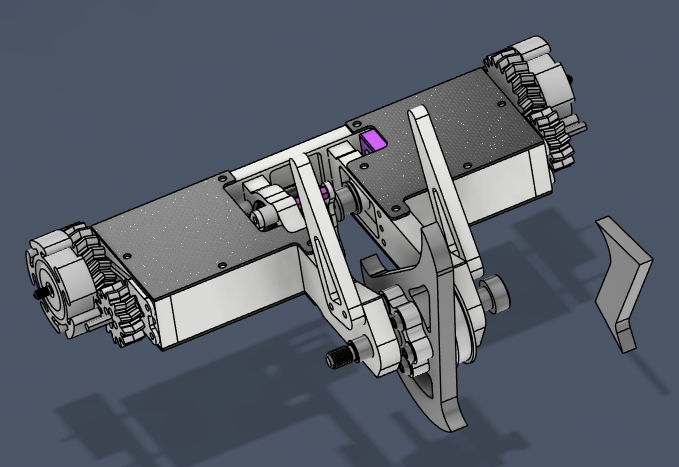

Here’s the final version. All mounted to a hardox plate with some additional bearings, spacers and plates to help with the shaft’s cantilever. The shaft itself ended up as a 10mm Titanium hex, machined by the awesome Morgan. With all the CAM, gear & spacer parts getting lasercut via LaseredComponents. We ditched the bearings as we’re using HDPE legs and having spoken to Luke Quinn briefly about the robot, he recommend not bothering with bearings and having a looser fit.

Here’s a nice video of it skidaddling the night before the event.

![]() Weapon

Weapon![]()

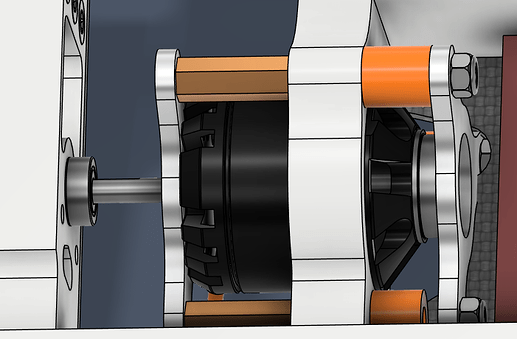

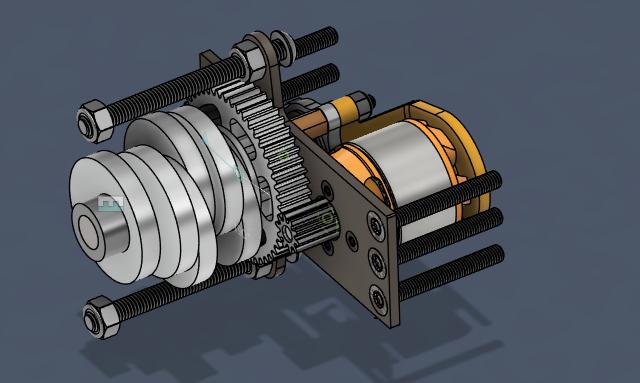

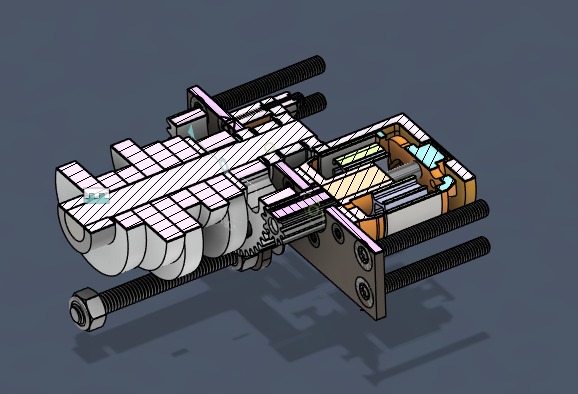

Initially power wise, wanted to use some goofy xteams 3674 inrunner, Ellie has good success with the brand on her Featherweight, and she took a lot of the lead with the weapon system itself (Nerd). But this thing quickly became a fucking shitshow to mount. So decided to swap to a 4250 outrunner. Ellis had recently started selling his Saturn lineup, and they fit the bill. General plan was to mount it within the weapon bulkhead using some 4mm Alu plates & standoffs. This lets us double support our weapon motor, hopefully giving us more durability. We got a custom shaft made up from Nat, with the goal of also double supporting the shaft using the other bulkhead with an additional bearing.

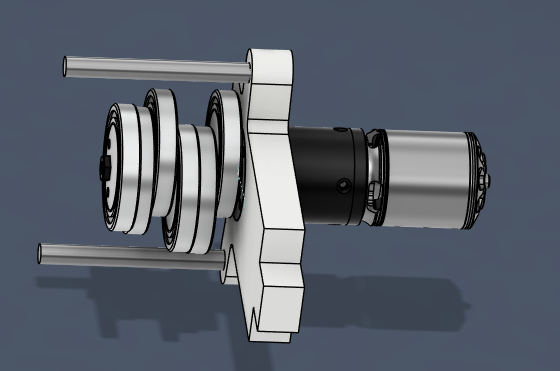

Motor with custom shaft.

Pulley & Spacer are made of fully Aluminium, machined by Nat who did a fantastic job. Ellie was quite adamant on Alu to avoid any melting. 6 M8s bolt through and thread into the pulley. Moving forward would deffo use only 4 M8’s and make it leaner. Just from a weight perspective. With some 16x31x10mm bearings inside them. With the biggest weapon discs, it’s about 1.5kg of spinning mass total.

Used T5 belts for our weapon, found a pulley which matched our ratio, then worked from there. Belts initially were super tight, but after getting them in a fight and them stretching, they became much nicer to work with.

![]() Building

Building![]()

Here’s some photos from building. Captioned appropriately!

Coutersinking hardox. Got a great bit from Jamie, thanks again!

Here’s the titanium hex, was either this or mild steel, choice was obvious

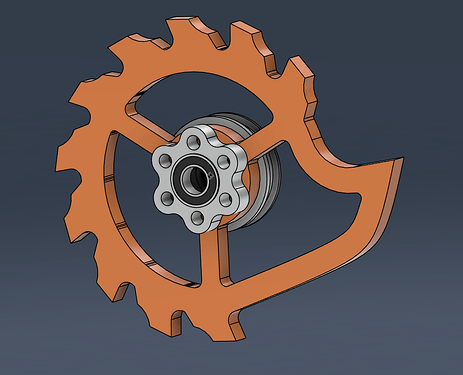

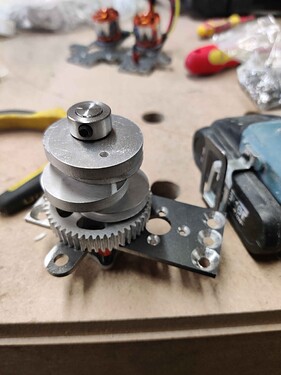

CAM stack up on the shaft. Gear, spacer, then all the CAMs

Here’s it all on the plate.

Machined all the carbon fibre lids and bases. 3mm base, 2mm lids.

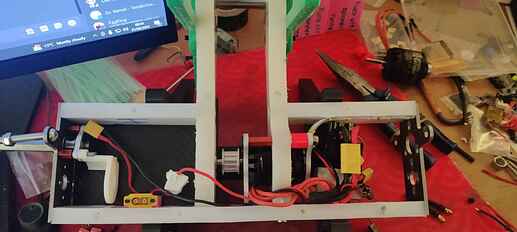

Wired up chassis of yellow, green got the same treatment after.

Green pre-op. Generally the wiring pattern is Lipo on left, all the rest on the right.

With weapons on, whilst the legs cast.

Workshop of legs. HDPE cut from Filo and I. Would use some harder shore, just because by the end of the event, the Polyurethane was just peeling off.

Half a frame of each, had Filo cut the backplate cuz it barely wouldn’t fit on my CNC.

Yellow whilst I waited for feet to cast.

Genuinely my favourite robot I’ve made of all time. Got some changes I’ll cover later but love these little guys.

I’ll have to do some digging for some finished photos, naturally they got finished morning of. So I was rushed to get photos.