design for yam started a few months back, been wanting to make another 2wd vert of some kind for a while but didn’t want to make a standard vert, wouldn’t really fit my style, so wanted to do something silly, the main inspiration came after scouse showdown 2, where sion had a really awesome 500 gram drisc bot, really liked the idea of building a silly heavy vert but wanted to try and make it more driveable, it was about this time i also saw ripperoni with its really cool anti gyro flywheel and i figured i might be able to emulate that with a tilting frame instead, i also really liked how much of the bot was off the ground to prevent forks being a factor so wanted to do that too, as the weapon and tilting assembly is the most interesting part of yam ill talk about that in-depth with a little bit on the drive ect at the end

so with these two ideas in mind i then also set myself the challenge of having the heaviest vert beetle in the uk, naturally the best way to ensure this was to make half the weight of the robot a spinning weapon, which was the first thing i designed

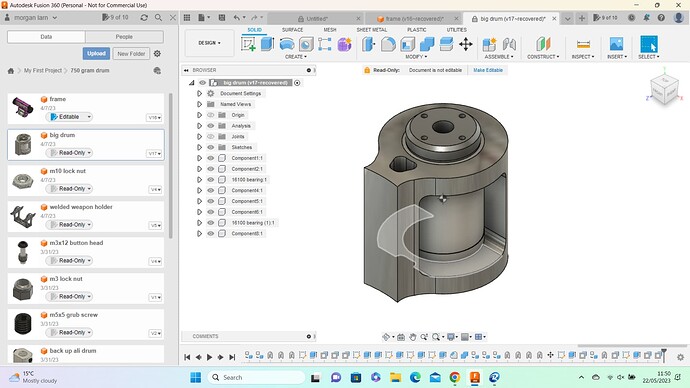

i knew from the get go i wanted a hub motor, it gave me the most spinning mass as well as ensuring i could keep it running after even the biggest hits

the weapon itself is 85mm diameter, i those this to ensure it was about the same diameter as traditional verts so it would be harder for them to out tip speed me as well as ensuring i had more bite than they would with over 12mm of tooth, this also meant i could have a better shot at getting massive impacts without needing forks

the bearings we 10mm id by 30mm id and 11mm deep on a 10mm grade 5 ti shaft, i did this to ensure i had lots of strength to take big weapon to weapon shots, as part of my gameplan was to run upside down to deliver enough energy to hopefully break the other weapon in a impact

the motor itself is a old brushless motor i had for another hub motor that i never built, its a 3536 propdrive of unknown kv (somewhere between 960 and 1800) im 99% sure its 1400 kv as thats the cad model i had from years ago but decided to run on 3s to be safe to ensure i was well under the limit at around 170mph

the weapon was made by pcb way from 4140 and i decided to try getting it chrome plated, it was like another quid to try it out so figured even it its useless then ive not wasted anything in trying

the core of the drum is ali machined by myself, there are several reasons for this, firstly i wanted to keep the cost of the drum down. getting them to machine the bearings pockets and motors was Gunna be costy, it was also done to prevent pressing bearings into hard steel, talking to other builders this is a bad idea and can lead to cracking, so hopefully the ali should act as a “pillow” between the weapon shots and the bearings

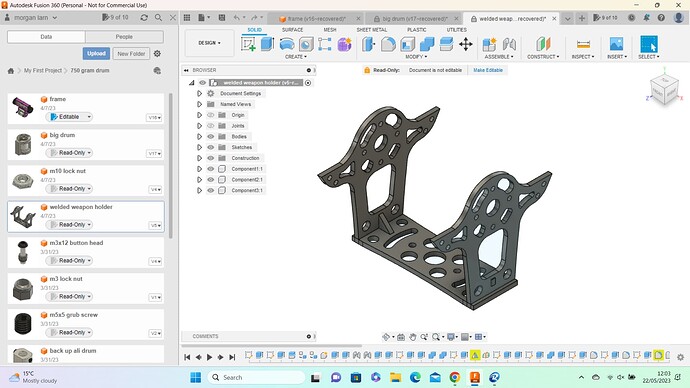

next thing i designed was the tilting frame, i wanted to ensure it was as strong as possible so opted for 3mm reax construction and a 12mm pin for it to pivot around, its designed to give around 20 degrees of tilt either side, this was a totally random number but figured it would be a good first test, originally it was of bent construction but opted for welded due to time

the tilting is controlled by 2 m5 bolts that run in the slots pictured, captured by 2 locknuts on each bolt to ensure it wont vibrate off

it is mounted to the frame by 2x2mm by 16mm flanged bushings in 2mm 6082 aluminium plates, the shaft itself was 12mm silver steel with a m6 cap head bolt holding the whole thing together

i also wanted to ensure that i didnt need to play the ground game, the supports from the drum are swept back and even rounded off, and the large wheels ensure i have a massive around of ground clearance (close to 20mm on the front) to effectively drive over forks and delivery the weapon effectively

the body is a tpu unibody designed to be as light and durable as possible, although mainly just to save me from the odd hits it might take with owobotics brushless drive motors paired with bbb brushless drive escs which worked out well, the other small thing of note is the rounded ali back sections these are just to prevent it getting it stuck on its butt

finally its got 2.75 inch foam wheels to save weight and stop me breaking the gearboxes on weird landings

so yeah thats the deisgn idea for yam, the build process went well, most of the pain was getting my printer to print the tpu at all, ill spare you the hours of pain to get it running as its still not reliable haha

so yeah, yam!