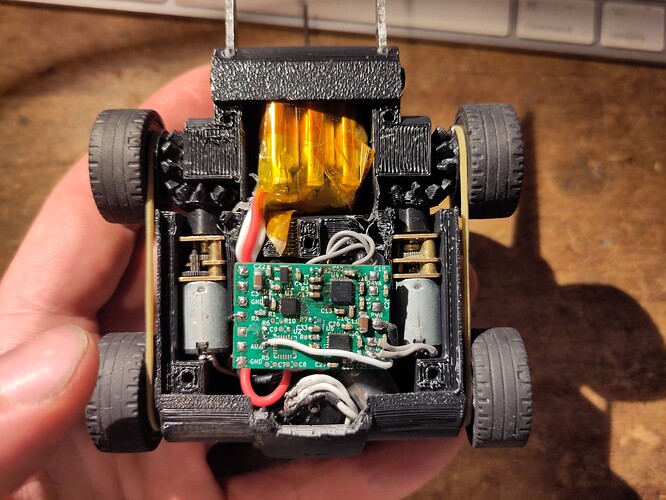

During the design and build of my beetleweight, Fatal Deviation, I ordered a small selection of different cheap compact brushed servos, to see how many would work at 3s. Turns out it was none of them, and I had to buy a really expensive brushless version as well (and then another, because I blew the first one up too in a late night wiring loom incident).

Fast forward to last month, tidying my junk boxes, I kept looking at the remains of the servos. There’s no way they’d fit in an antweight, right?

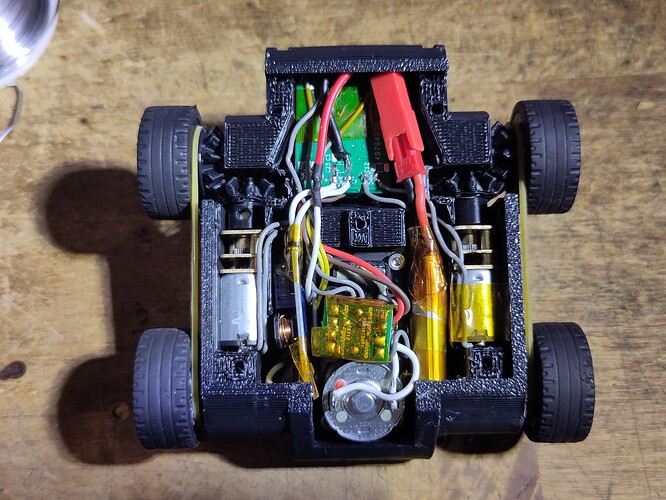

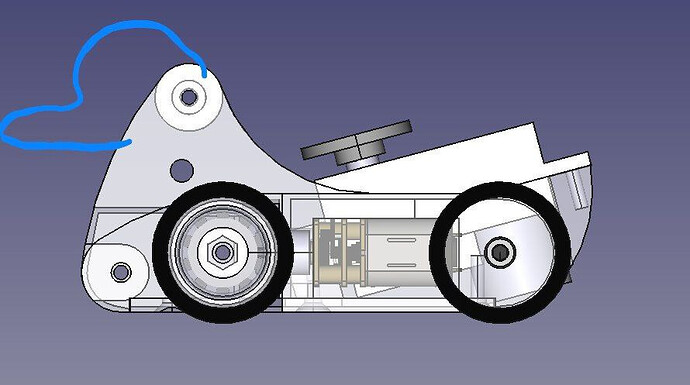

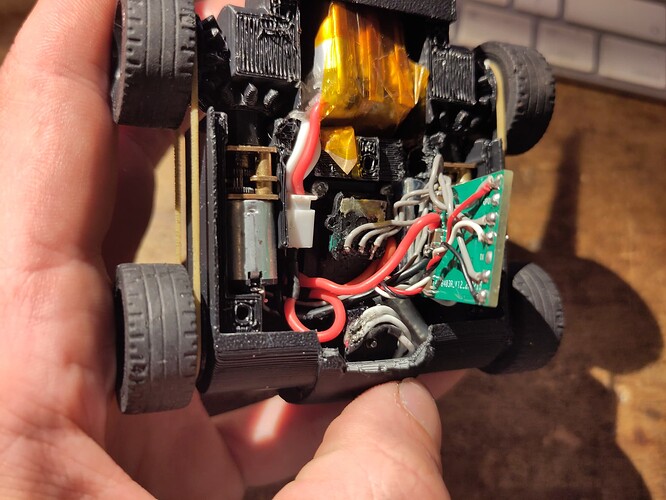

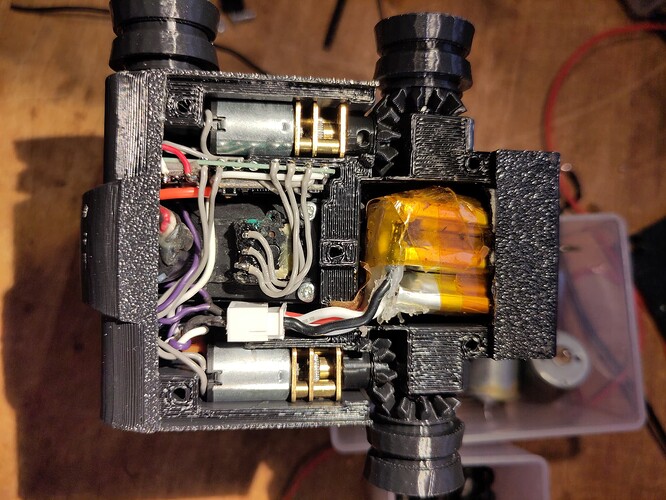

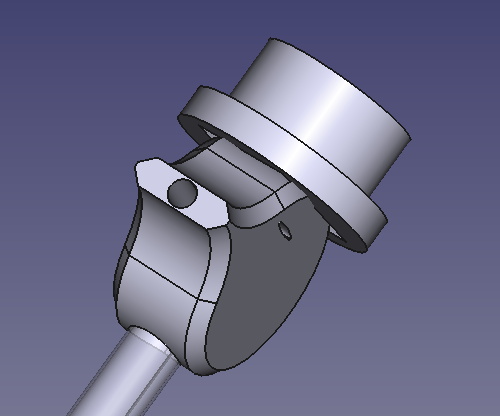

Turns out that when shaved to within an inch of its life with flush cutters, this one does. I used the one weird bevel gear trick (again) to run the motors longitudinally, parallel to the servo, but with gears 3D printed into the wheel hubs*. This gives just enough room in the remaining space for the same 1s + 12v boost converter setup that Fatal Deviant uses, although I had to forgo the gyro on this PCB because I needed the pins for the motor driver IC hanging off the back of the servo.

*you know those little brass top hat spacers you get a little baggy of free with every servo? Ideal antweight hub bushings. With a dab of grease they run real nice on an M3 screw and only weigh 1/4g each.

Usual tight fit inside. Please forgive the soldering, this was a fit check, honest!

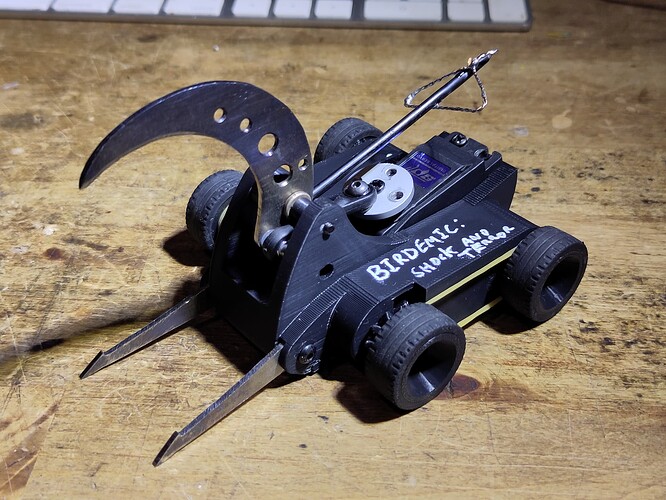

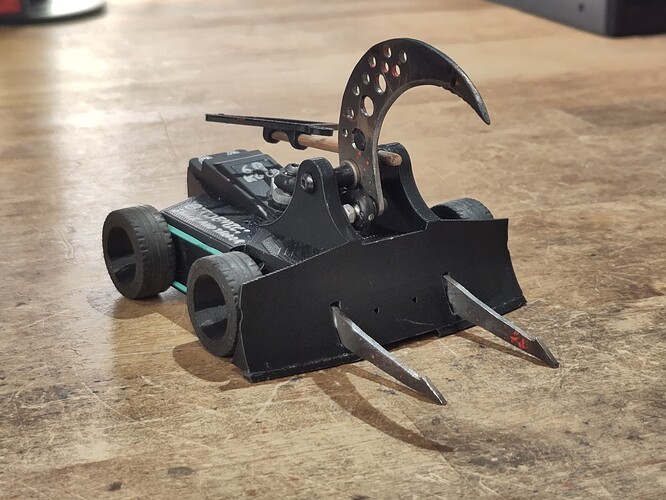

I decided the name because I kept seeing a rubber duck when I was working on the CAD, and given my B movie naming themes I had a choice between Birdemic and Thankskilling. Thankskilling is about a possessed turkey and we’ve already had one (much cuter) poultry themed crusher robot this year, so Birdemic: Shock and Terror it was.

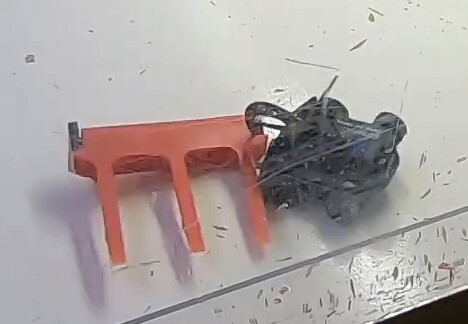

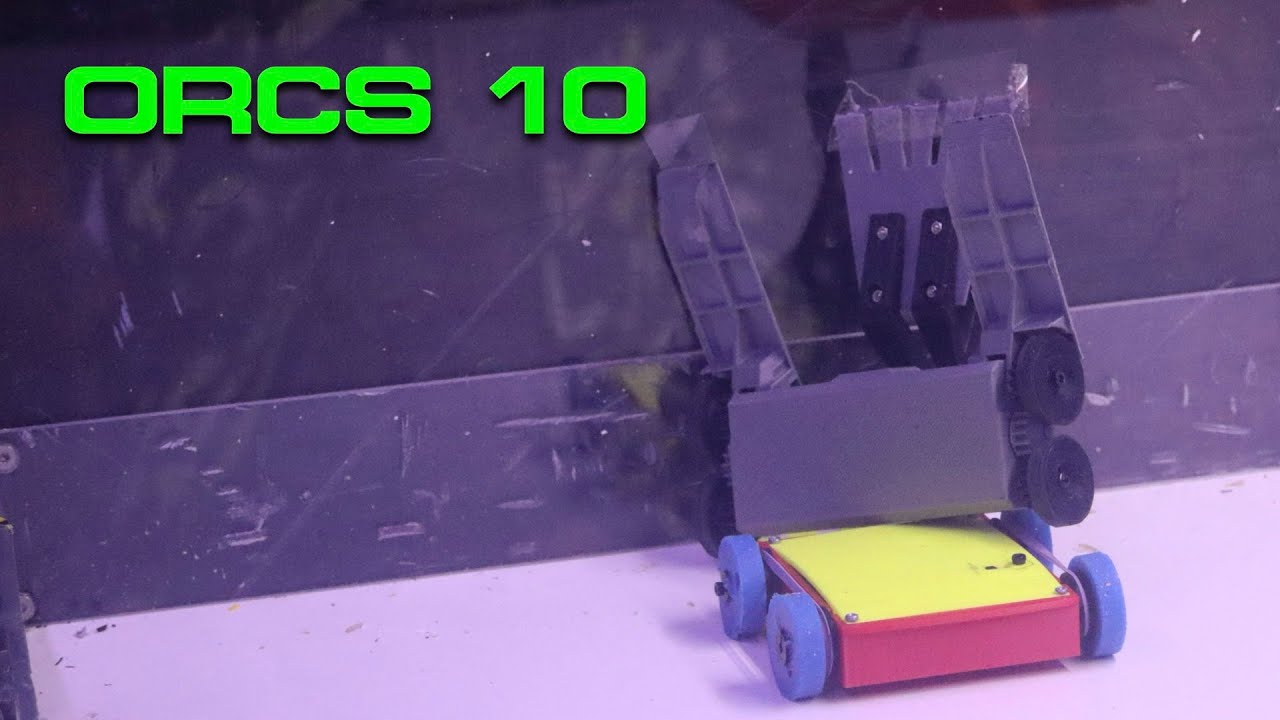

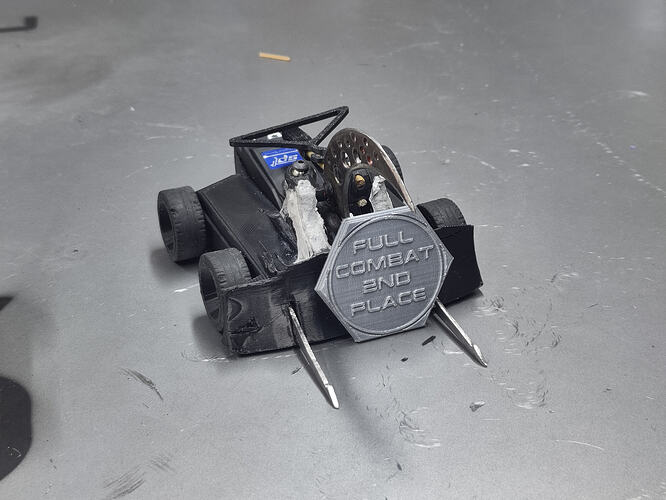

It managed to make it to ORCS for some whiteboards, where it performed really well for a bot finished at midnight the night before. It drove pretty good, was able to self right (before the self righter glue came unstuck), and got some good grabs in, including one on the arena wall on its way into the pit, allowing me to throw the robot back onto its wheels inside the arena and into the fight again.

For future improvements, a custom PCB is in the works. This will cut down on wiring spaghetti, and also allow me to move away from the boost converter to a real 3s pack. Currently the weapon is current limited by the boost converter to 1-2A and acts mostly as a grabber, but the final goal is for it to perform as it does here, when allowed to pull its full 5A-6A stall current: https://youtu.be/-fP4krnDY-w

I’m also hoping to improve the drive further, these aliexpress N20s struggle to overcome the stiction in the bevel gears and belts at low speeds, so low speed control is a challenge. I’ll start by gearing them down a little, but I’ll likely end up swapping in some spicier N10s to save weight at the same time. With more power it’ll need more traction, so I’ll play with some different tyre options.

Finally, that titanium crusher arm wasn’t built for this bot. It was designed for an unnamed drillium titanium framed bot I was working on that was intended to use a lead screw N20 pulling some braided fishing line, but it didn’t quite work out. I don’t like posting unfinished bots because I need some motivation to finish them, but I thought since part of it is making an appearance the rest should too. I only built it because I made the wedge for Fatal Deviant but it was too heavy, and I didn’t want to waste it…

See y’all on the 20th. Bring spare top plates <3