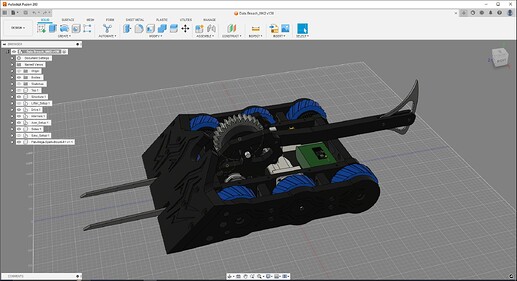

Data Breach is my 6WD Beetleweight that I first built in 2023 and competed at the Robot Rebellion 2023.

This build log will cover the original build and future versions for Data Breach.

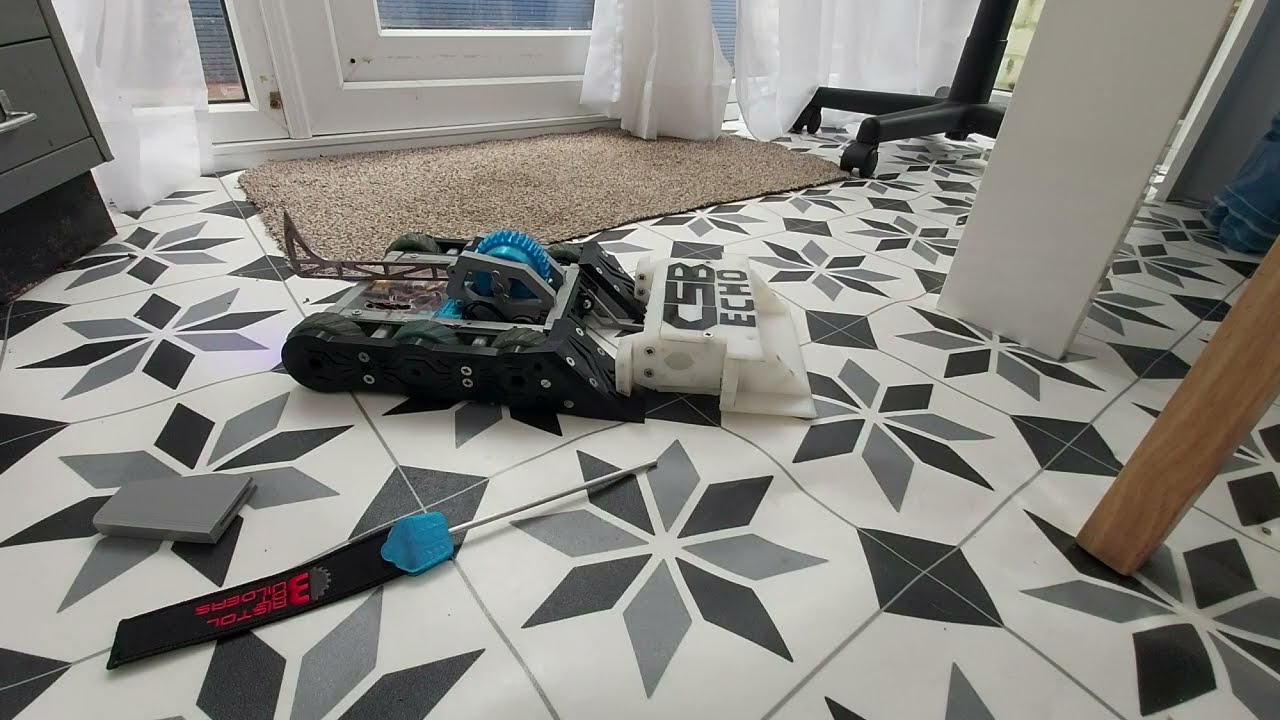

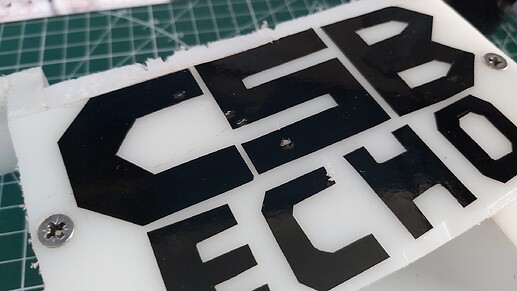

After the disaster of a performance at the 2022 Robot Rebellion with my previous Beetleweight CSB: Echo, I had to take my Beetleweight endeavours up a level. That drive started when I had my post-fight interview after Echo went 0:5. In that interview I made a big “public” claim I would return with a 6WD bot.

A bold claim to make seeing at that time there was only one other 6wd Beetleweight in the works. But I had been working on a few concepts for a 6WD Beetle for a good while. All of those were CSB: Echo 2 concepts but with my recent track record, I wanted a clean slate.

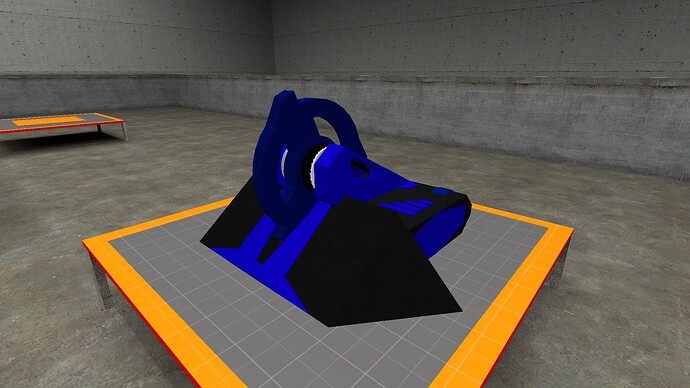

Data Breach takes its name from a blue and black vert I made in Garry’s Mod

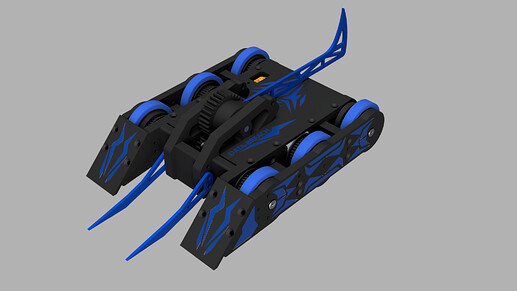

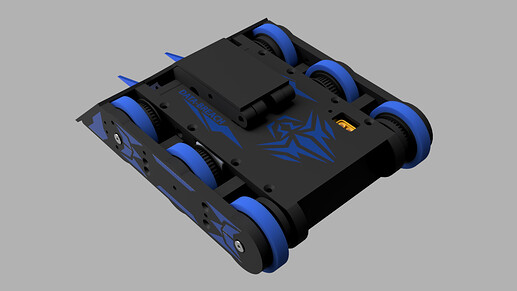

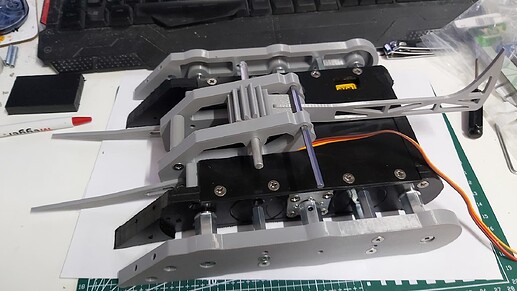

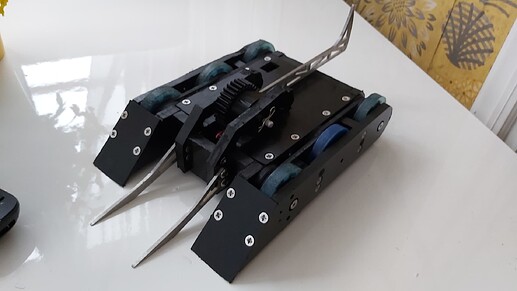

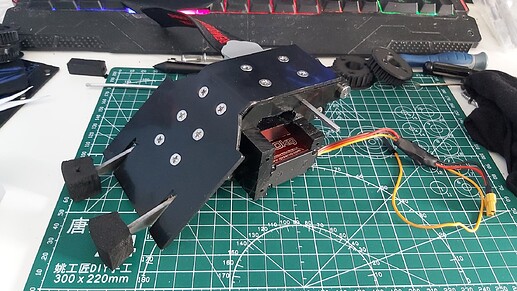

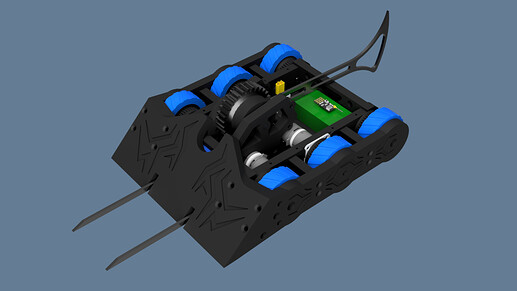

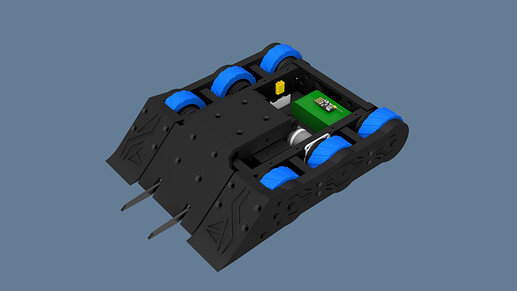

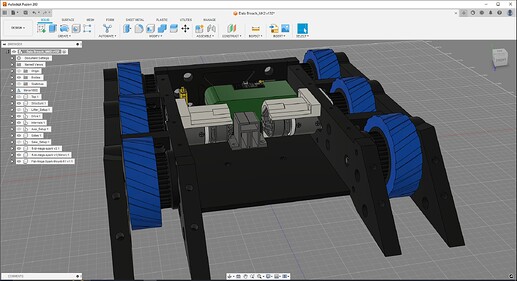

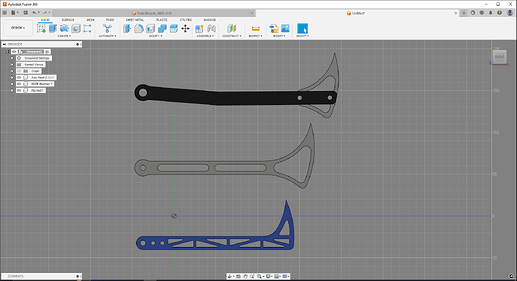

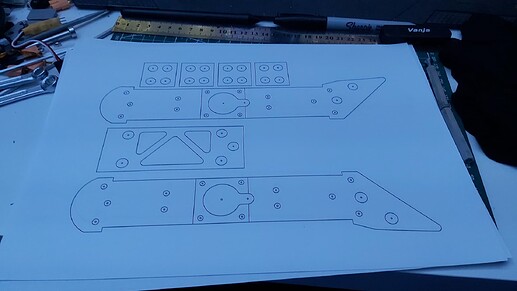

While under the working title Dust And Echos (a nod to two bots I worked on at the 2022 event.) I CADed away for the rest of 2022 and a good amount of 2023 too. Below are the 99% finished CAD renders for the Axe and Lifter modules.

The worst-kept secret was the Swiss army bot aspect. I said I was making a 6WD bot but I never said anything about weapons. But I couldn’t keep that surprise under wraps for long.

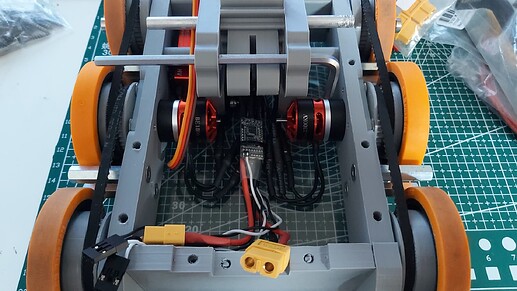

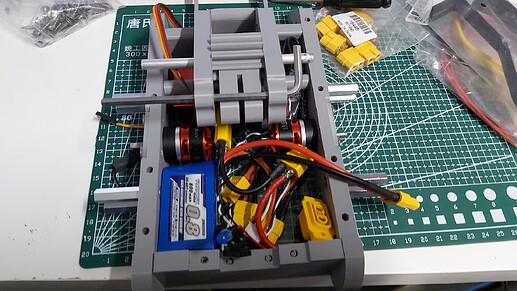

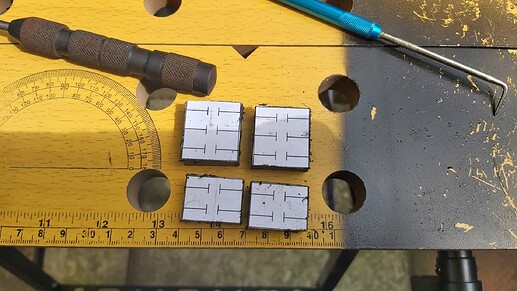

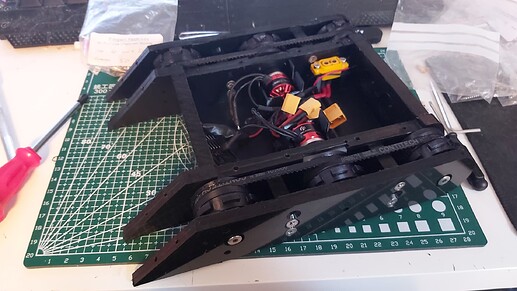

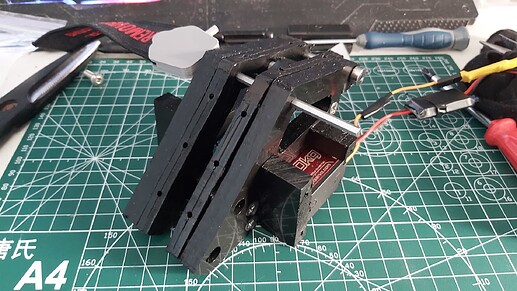

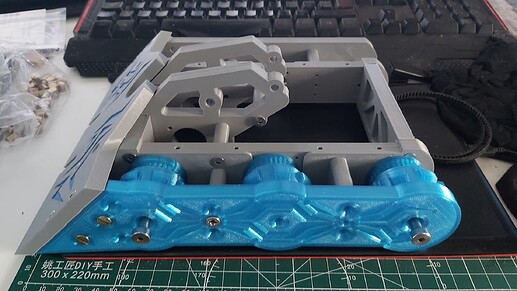

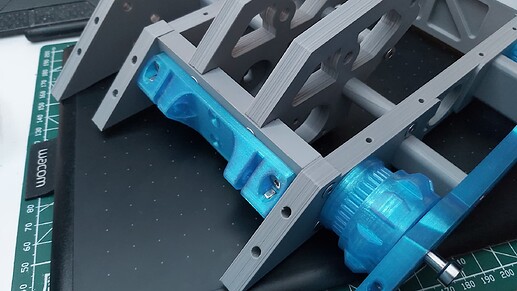

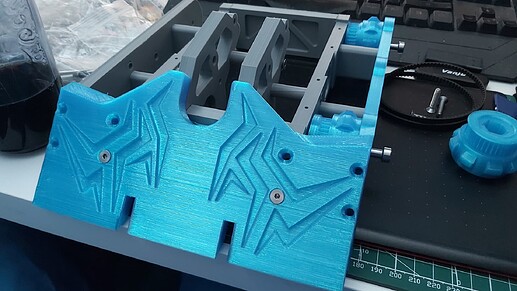

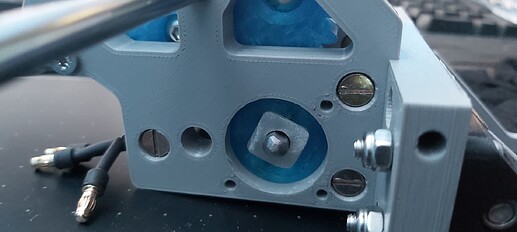

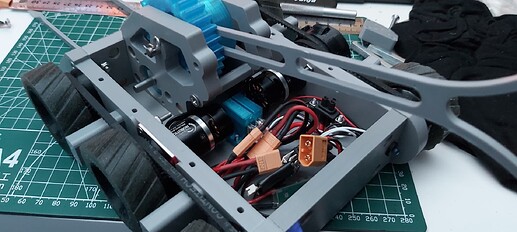

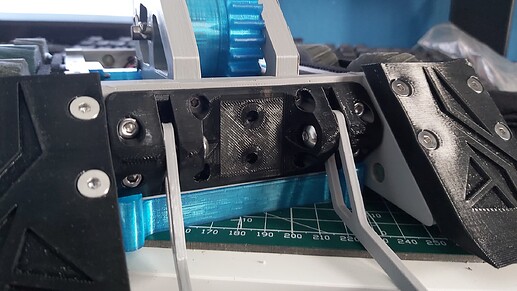

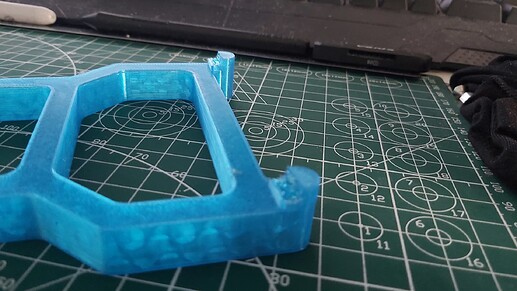

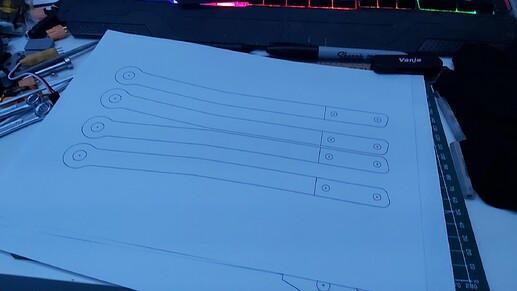

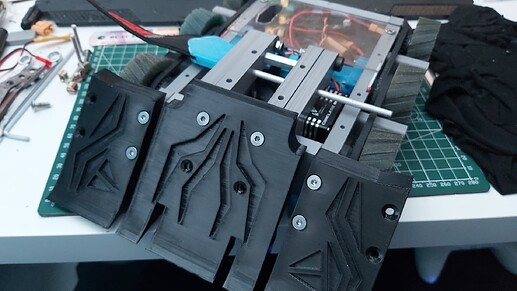

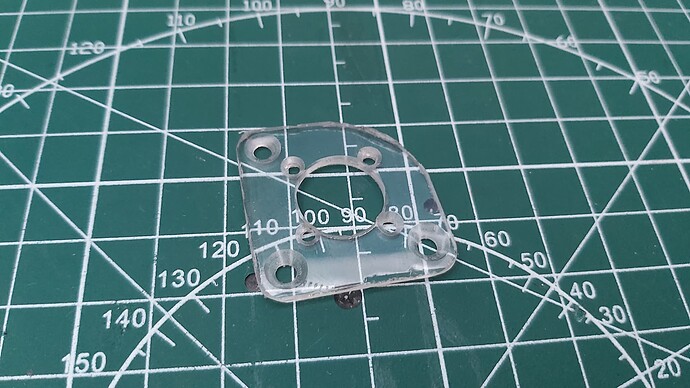

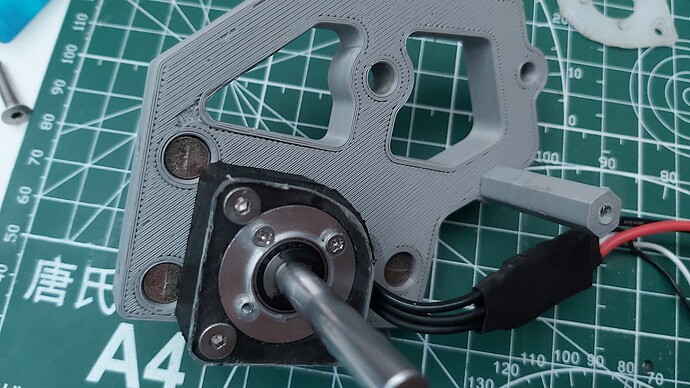

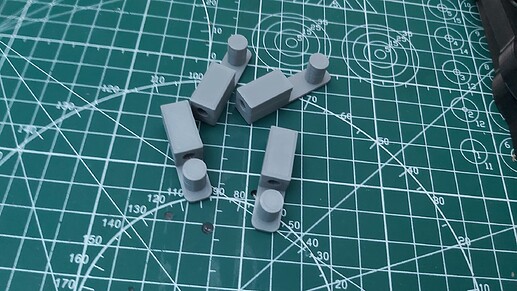

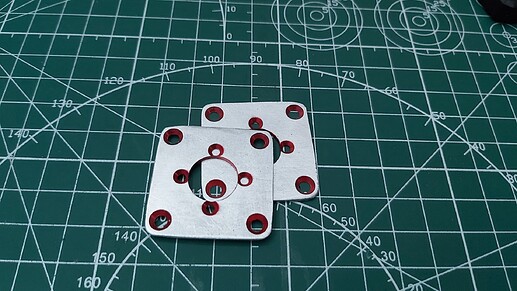

While I CADed out everything I would prototype the design with 3D-printed prototype parts made out of PLA. These helped me test fit internals and grasp the scale of the end product and test out different ideas on dead shafts, mounting patterns and how the sides mount to the bulkheads.

Below are a few examples of different PLA prototypes.

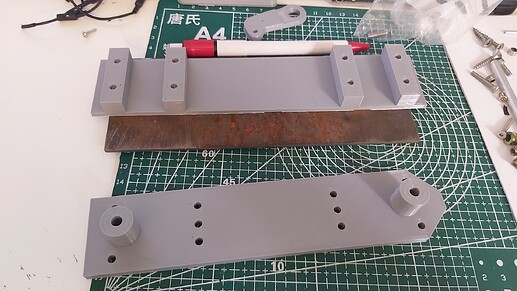

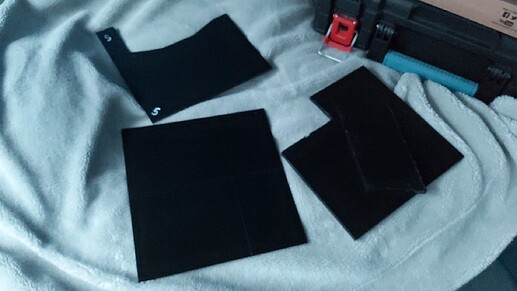

As you can see I was prototyping at lots of stages of the build as some of the 10mm Bulkheads and the 3mm top and bottom plates were already made.

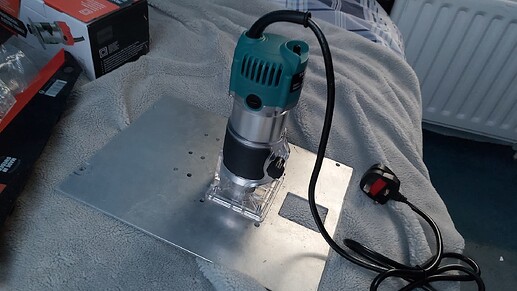

All the HDPE was hand-made by myself using my drill press, Jigsaw, my newly bought router and my go-to printed templates glue stuck onto the HDPE. I would use some 3d printed Jigs to install the threaded inserts, to cut and drill the smaller HDPE parts and to fix a misplaced hole in the Hardox wedge I had made in case the weapons died.

Yes not the greatest of router cuts but this provided the slot needed to fit the BBB into the bulkheads so it was entirely flush so the wheels were perfectly aligned.

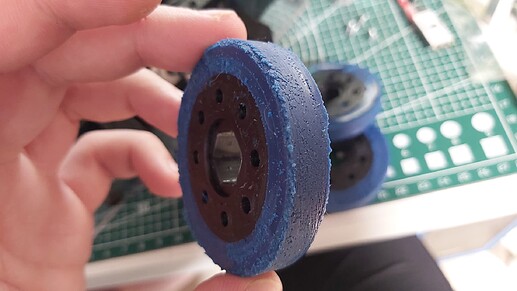

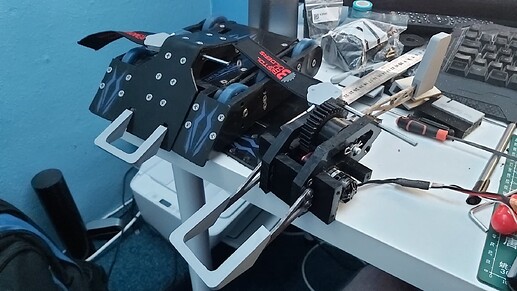

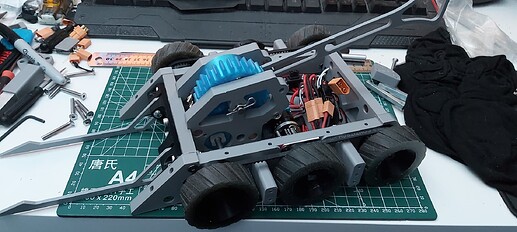

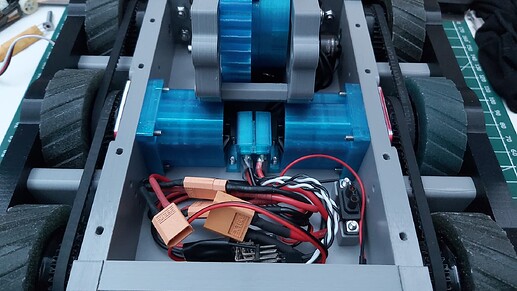

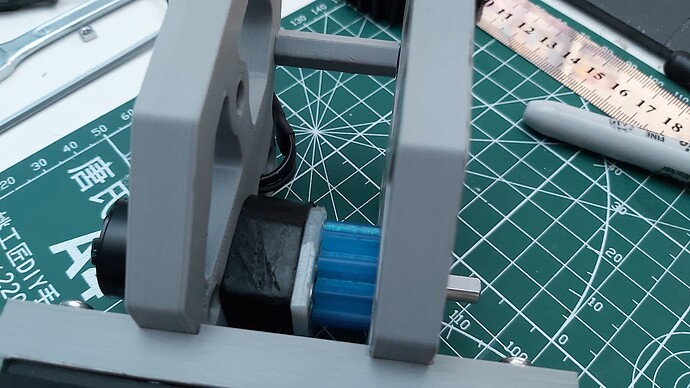

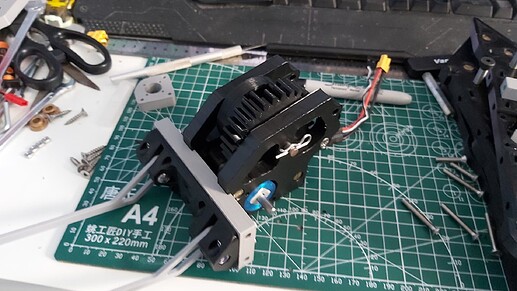

A near complete chassis. Here you can see the nylon 3d printed pulleys and wheels with the 4mm wide HTD 3 belts. A good chunk of the Nylon parts was printed by Ranglebox as my filament proved faulty.

I wasn’t well-versed in designing single-piece wheels and pulleys so I just made them separate parts.

The hex holes are for slotting onto the aluminium hubs machined By SC Robotics based on BaneBots hubs. The middle, drive hubs had 4mm holes and the driven hubs ran on 5mm shoulder bolts with bushings fitted inside.

The motors were my conversions of BBB 22mm motors with 2300kv 1806 brushless motors also available from BBB. These conversions while they worked were not ideal. Too fast and as I discovered after Robot Rebellion 2023 just a little unreliable and hard to service.

This test video highlights how bad it was to control the dual rates at 100% At the event I had Data Breach at 50%

Sadly the test also made a mess on the floor the polyurethane rubber tyres I cast used a little too much pigment and shredded like cheese.

And sadly these were just some of the teething issues that cropped up.

The 3s 850mah batteries from CSB: Echo were running low after just two minutes of running. I then bought some 1000mah lipos to resolve that worry.

The worst teething issue was the weapons. AHHHHHHH

Both the Axe and Lifter couldn’t self-right and the lifter couldn’t even lift.

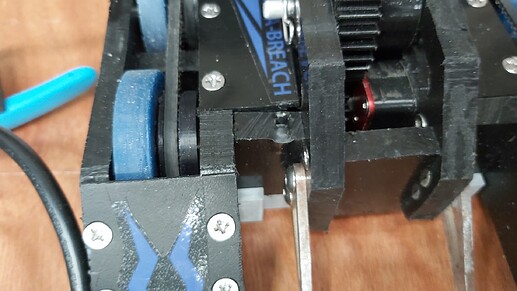

The cause of the Axe’s issue was the 3D-printed gears that made up the second stage of the Axe mechanism. The Axe uses a 2300kv Fingertech Mega Spark with 2 nylon gears in mod 1.5. The smaller gear had a recurring issue with stripping out the inside allowing the 6mm Mega Spark shaft to freely spin inside. I ended up fitting an m3 square nut inside to extend the gear’s running life (2 and a half fights to be exact.) The other issue was the gear ratio. I had the Gear ratio at 2:1 which proved not enough. I upped the ratio to 3:1 and happily it fixed the issue and now Data Breach can throw itself into the air.

The lifter’s issues were a combo of browning out and bad geometry. The 30kg servo (I had bought for a planned lifter upgrade for CSB: Echo) wasn’t rated for 3s so needed a BEC but it was a low amp one and the servo needed more. I was directed to a better BEC so electronically the lifter was sorted.

The geometry issue was the shape of the lifter arm and the points of connection for the linkage between the arm and the servo.

A redesigned lifter resolved the lifting and self-righting.

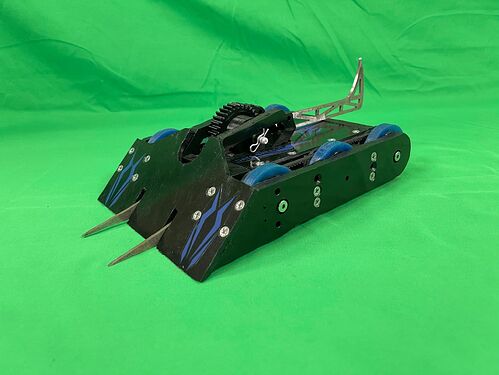

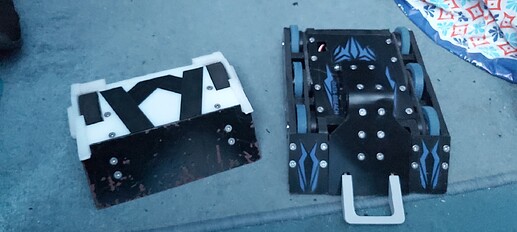

With both weapons sorted it was time for a weigh-in. The Axe setup was 1.35kg and the Lifter was 1.3kg

Around that point, I learned what robots I would be fighting in roughly 2 weeks. Using that knowledge I made an “ablative” wedge from 5mm HDPE for taking vert hits as I was worried about the weapon bulkheads taking hits. I also made an 8mm top armour for hammer saws. I would fit these onto the Axe setup to have a heavy setup of 1.45kg.

With the decals added Data Breach was as ready as could be here was its beauty shot post-Tech Check.