Time for a long overdue event report from Subterranean Showdown.

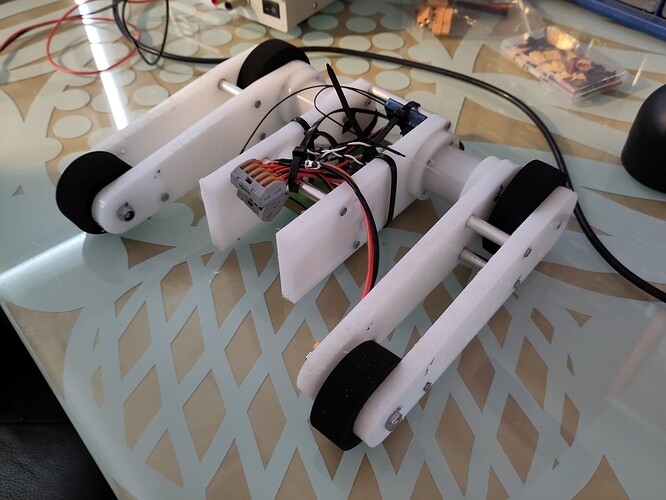

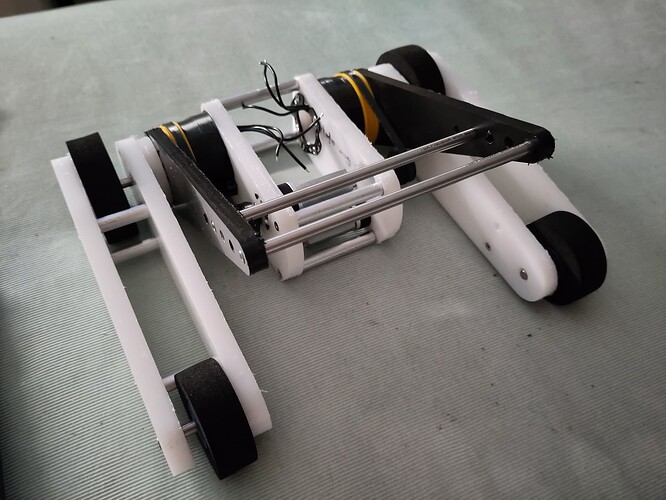

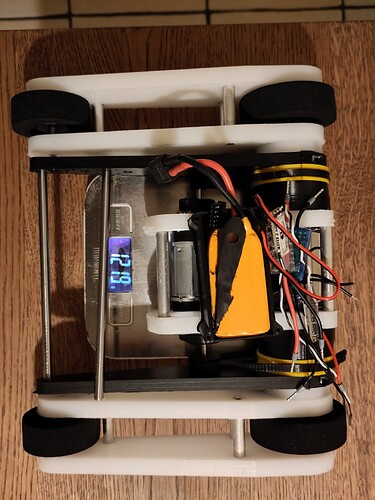

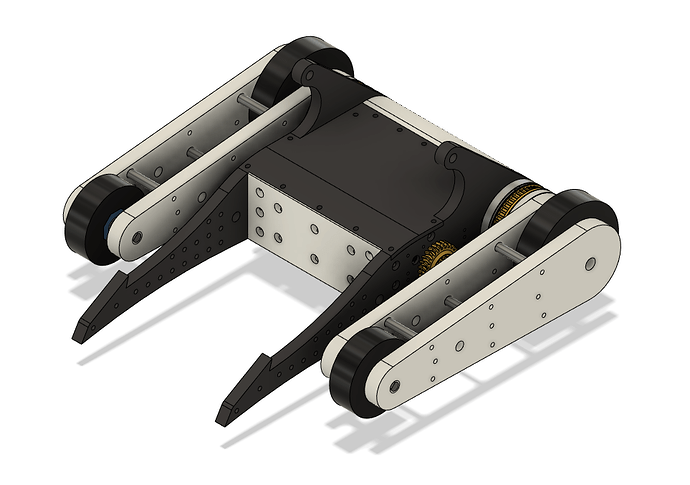

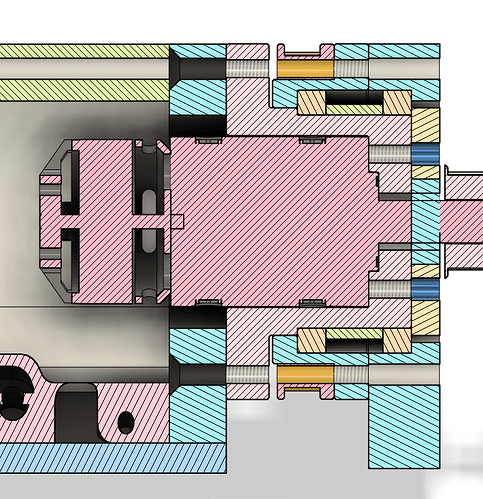

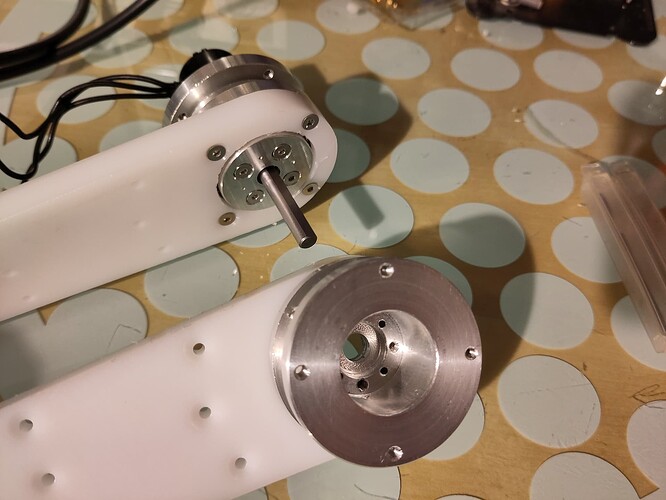

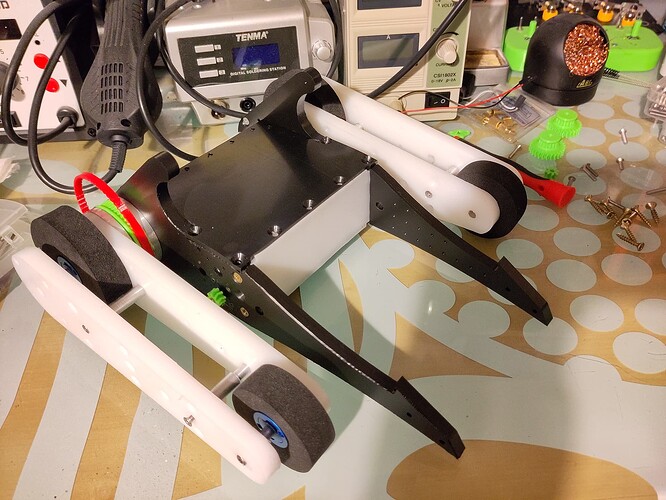

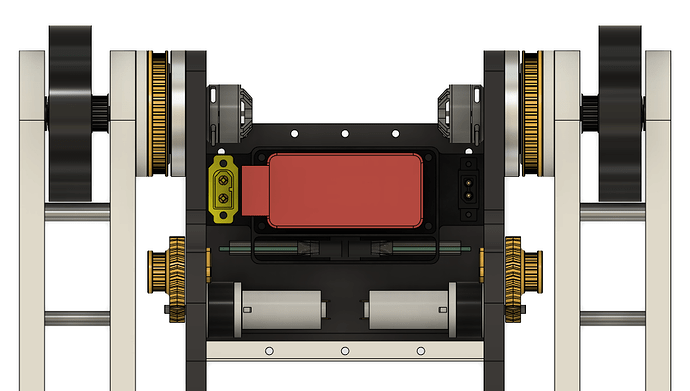

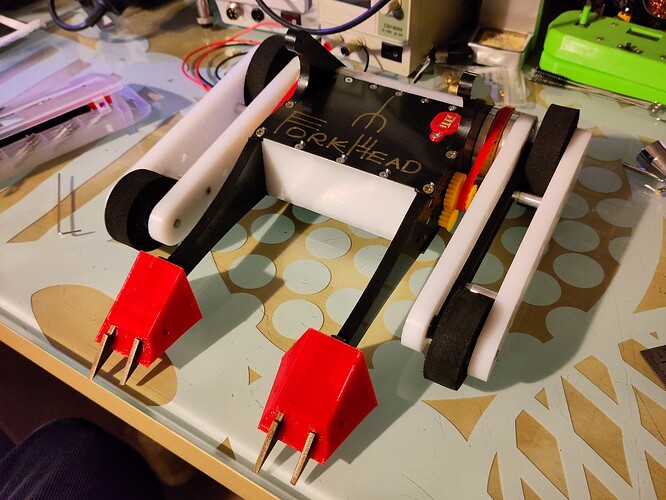

In the few weeks running up to the event I spent a lot longer than expected just trying to get a pulley setup for the lifter that didn’t slip before showing any movement. I ended up using printed GT2 timing belts printed from TPU and a mix of TPU and ABS pulleys, with the pulleys ending up smaller than they should be due to constraints that I couldn’t work around. Once the issues with pulley and belt sizes were resolved I hit a new issue with the pulleys slipping on the countershaft, leading to a whole bunch more experimentation to get that working.

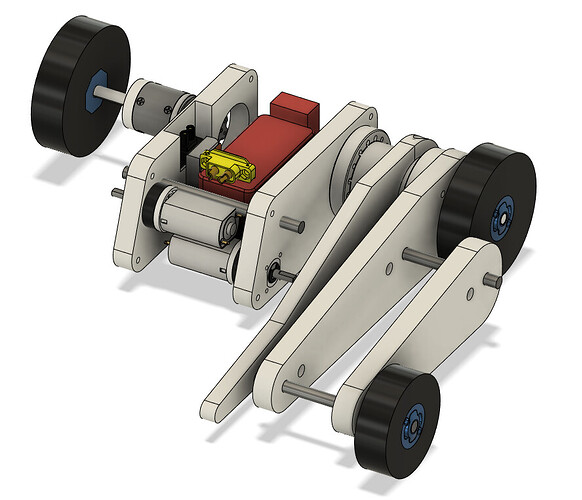

The final setup for the event ended up being two 22mm (one each side) brushed motors with a 16T TPU pulley pressed onto the shaft, driving an extra wide 28T pulley on the countershaft, the other end of which drove the 80 tooth pulley attached to the lifting prongs.

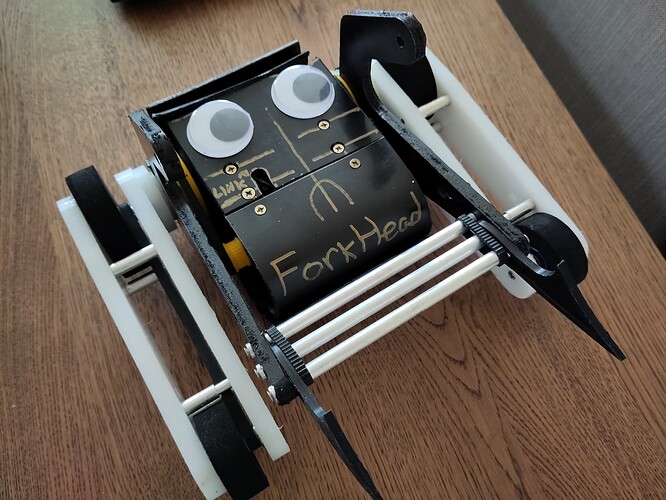

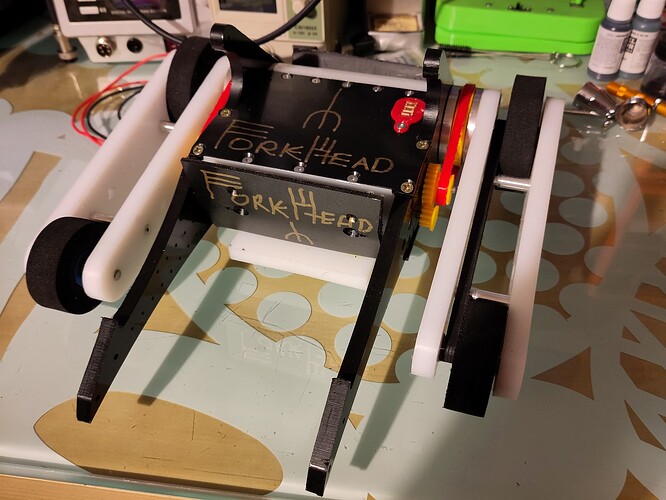

I benefitted a lot from Sam’s misfortune with getting Eye, Robot working in time and without his assistance I don’t think Forkhead would have been able to enter the competition either.

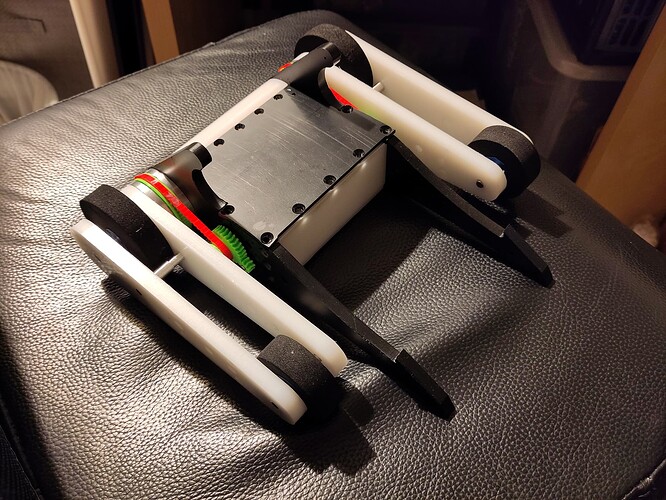

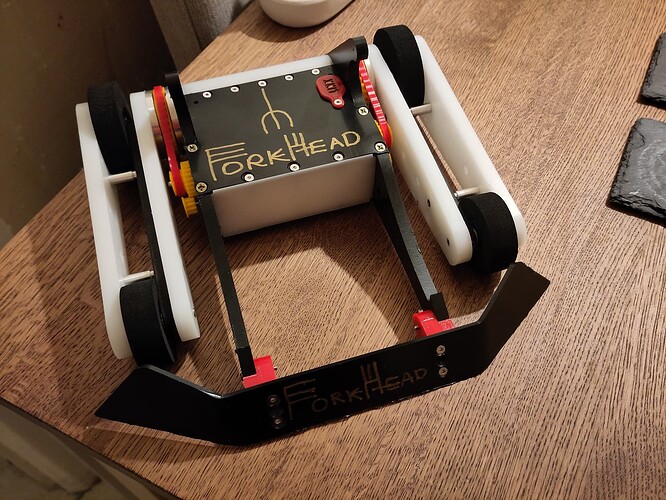

I managed to get things pretty much working the day before the event except for assembling the robot and enclosing the electronics pod, though the final assembly got relegated to a 2am building session once we’d made it down to Bristol and checked into our accomodation, and the enclosure ended up getting finished on the Sunday morning. Fortunately I’d clocked on the Saturday morning that I’d miscalculated the ground clearance and was able to order some larger wheels for delievery at the event, otherwise it might have been a write off anyway.

Once at the event I made it through tech check fairly easily, but instead of getting the larger wheels on I spent a bunch of time trying to get one of the various fork variations I’d designed and made, but not had opportunity to test, attached to the robot. After a bunch of time fighting with springs I gave up on my primary fork plan and switched to some bendy TPU forks that were much easier to fit.

Fight 1 vs Blast Furnace and Foo-d Fighters (a cluster of 4 smaller bots). Unfortunately ForkHead immediately demonstrated the predicted ground clearance issues which eventually led to its demise. The fight started with a disappointing lack of movement, but fortunately the prongs were mostly working and I was able to get the robot to sit on the rear prongs and the front wheels for a bit of mobility, but this gave me intermittent drive at best. After the Foo-d Fighters were mostly defeated Blast Furnace managed to push Forkhead to the far side of the pit where its ground clearance issues prevented escape before the pit button was activated. I managed to get some drive eventually, but too little too late and my attempt at escape led to ForkHead pitting itself with a dramatic swoon.

Fight 2 vs Righeous Death Toucan, another lifty grabby robot that was significantly more finished than Forkhead was. I fitted the larger set of wheels that I hadn’t had time to install before the first match, and we had an excellent grapply driving fight which came down to a judges decision, with the Death Toucan taking a well deserved unanimous win.

Fight 3 vs Eva 001. This was a very short fight which started very promisingly when ForkHead managed to lift and flip Eva 001, but then went south almost immediately after as Forkhead lost power after some grappling. This turned out to be the fuse wire in the removable safetly link shearing off. This was a frustrating way to lose, especially as the robot was starting to show some promise (and because I’d considered switching out for a different link seconds before the fight for entirely superstitious reasons).

That was Forkhead out of the competition, but the initial teething problems were resolved it was starting to show some promise.

Whiteboard fight vs Tsuchikage, Impulse, and Bop. This fight was great fun and Forkhead’s performance continued the upwards trajectory it had been on throughtout the day, managing to push some bots around and generally be a nuisance. Unfortunately this was cancelled out by my driving performance steadily decreasing from lack of sleep the night before, and ForkHead’s day ended when a drive across the arena put in the put, which despite the siren I’d failed to spot opening moments before.

I had a great time at the event, and despite teething problems I think the bot showed enough promise to be worth taking further. I’ve definitely got a few plans to underway to get things working better.

![]()