I’ve finally made a new solo build video, I am not a huge fan of talking solo to camera… I used to do this more often, I think it was more useful when I used to do builds by hand with much less CAD, but still good to share the process I guess… enjoy! It’s got a good summary of my last few years of builds and what kinda thing I try go for ![]()

To summarise the build in text form:

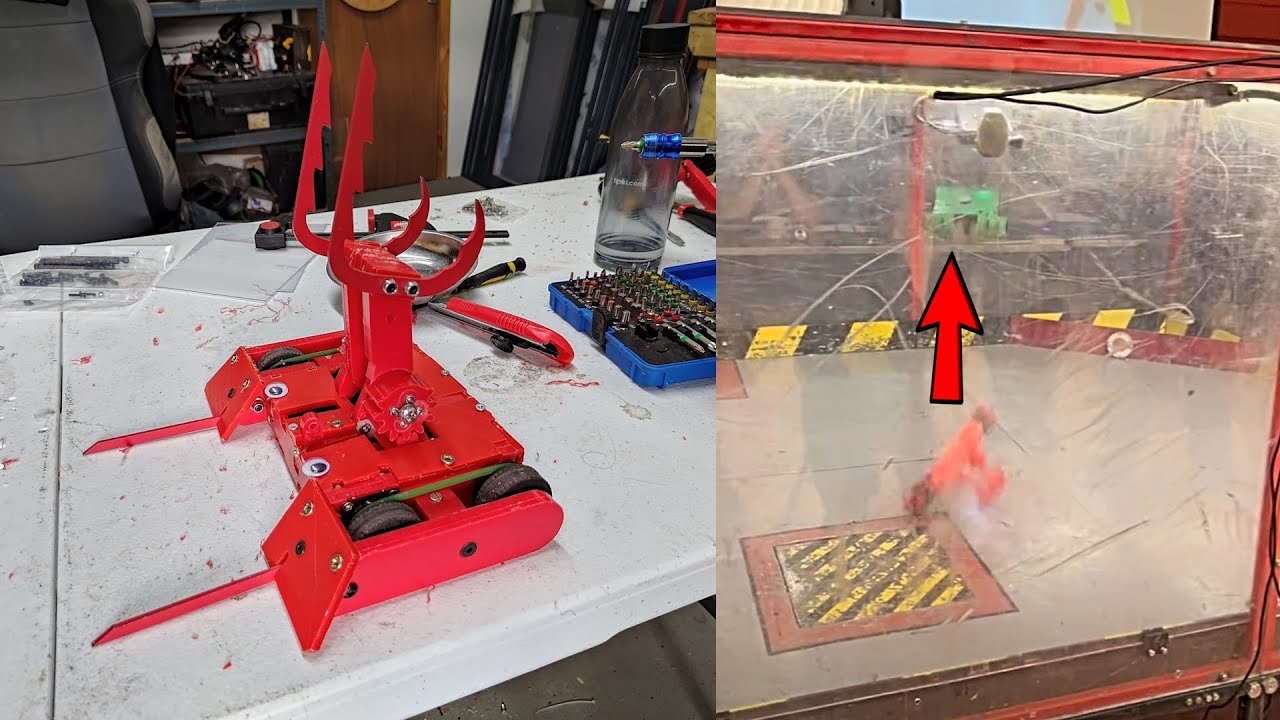

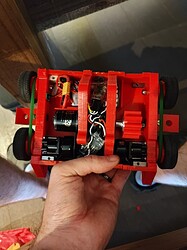

Firstly, here’s grab crab v3 before rapture 2022:

And after:

I had an onslaught of spinners and was super happy to come off ok against most of them until I got very stratus’d.

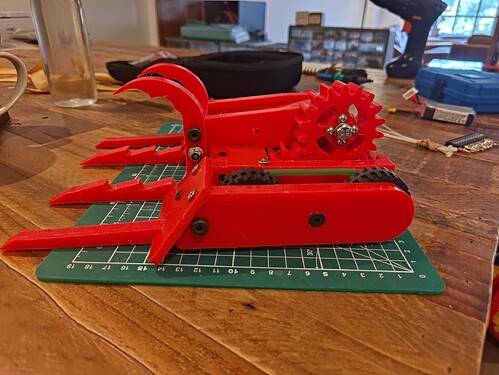

So for v4, I decided to keep most of the same chassis design with a few tweaks, but try out a new beefy motor - the ‘strangbox’ - @Strang_H’s set up on bonbonbonbon’s lifter - a 2836 on 100:1 28mm gearbox - BEANS!

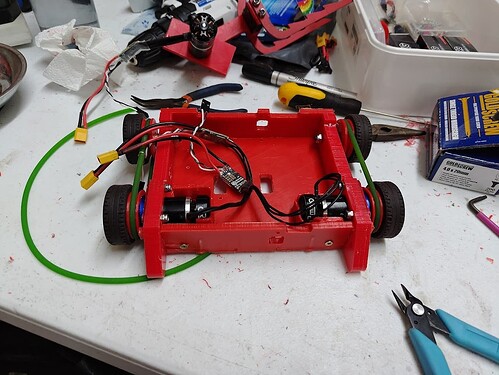

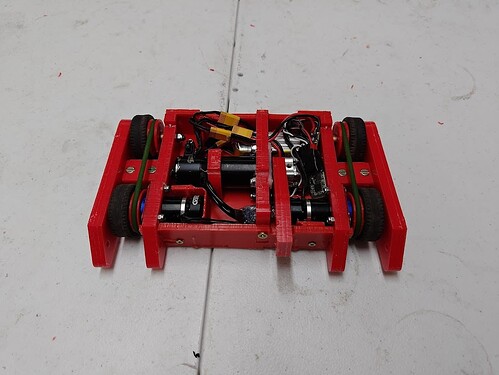

The chassis was my usual CNC’d boxy red HDPE PE500 interlocking 5 and 10mm:

Now upgraded to repeat max drive (had been great on ![]() Lob-ster earlier in the year, and repeat AM32 ESCs which seemed very responsive… so responsive in-fact I ran one on the weapon too. I decided toothed belts had caused me enough pain so stuck with trusty PU belt on drive and fun lego tyres, with TPU cores printed by the excellent Joe M!

Lob-ster earlier in the year, and repeat AM32 ESCs which seemed very responsive… so responsive in-fact I ran one on the weapon too. I decided toothed belts had caused me enough pain so stuck with trusty PU belt on drive and fun lego tyres, with TPU cores printed by the excellent Joe M!

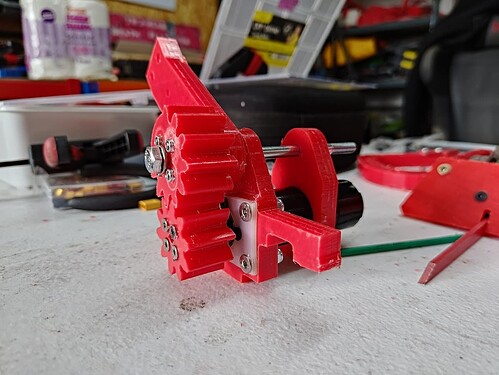

I’d initially mounted the weapon motor for direct drive as in my innocence 37D motors happily stall out this way

I’ve now used barrel nuts and HDPE spacers for the wheel guards, these held up sooo much better than the puny aluminium standoffs in v3

But in my testing, this had way more power and was going to tear the D-hole into a… well hole I guess. So I tried a series of 3D printed gears, see the video for the full run down on that, the summary was the gear teeth were too small and shatterable whatever the material (PLA, TPU, Taulman 910, ABS…) so wouldn’t really work without a pretty major redesign, which I at this point did not have the time for!

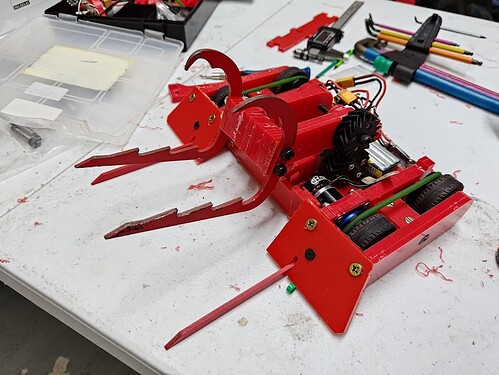

Using 3mm hardox forks and claws, now reused from both v2 and v3, one here a bit bent from Stratus but still very usable!

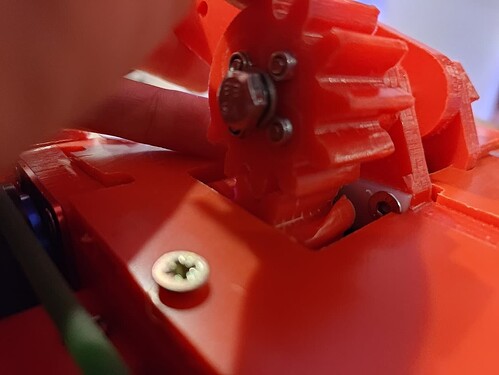

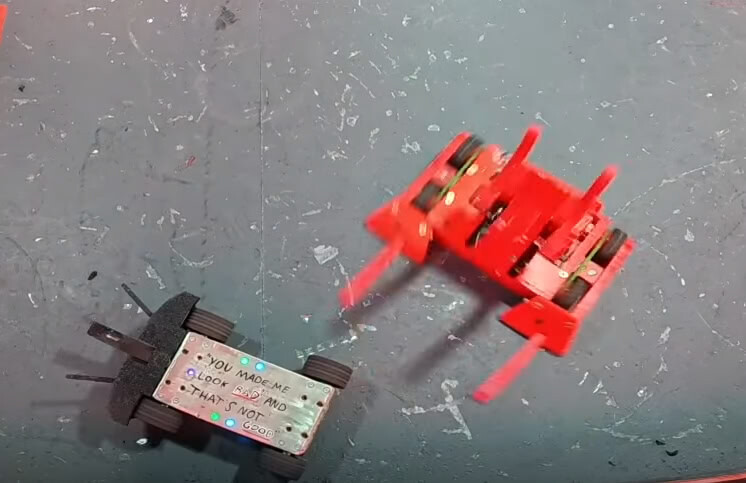

So day of the flight to Burgh (cutting it very fine…) taking influence from the excellent Tosser electric flipper by THE @Gareth, I went for as chonky as I could fit 20mm wide HDPE CNC’d gears

And these worked well enough in a quick test, no teeth exploding, no crunching noises. Still had to be careful to not stall out too much! So finished bot, ready to head to Battle in the Burgh!

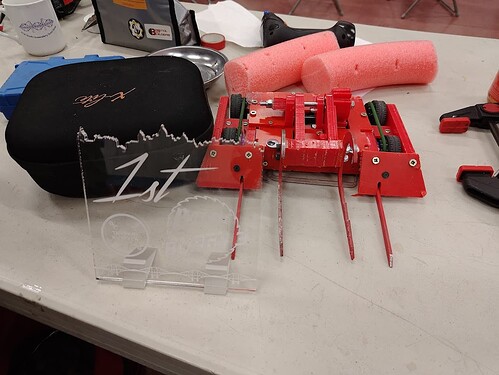

Full run down of fights in the video above, but due to some good yeeting and quite a nice draw managed to somehow come out on top?!

with an all control bot final with the excellent Boom Zoom getting some air miles!

Gonna whack this weapon motor on ![]() lob-ster next with a lot of HDPE gears, because chonk plastic gears are fun. GG, thanks for reading. See y’all in 2024.

lob-ster next with a lot of HDPE gears, because chonk plastic gears are fun. GG, thanks for reading. See y’all in 2024. ![]()