I got stuck when I designed myself into a couple of holes that I couldn’t get out of and put this project down for a few months. A few things happened that got my motivation back.

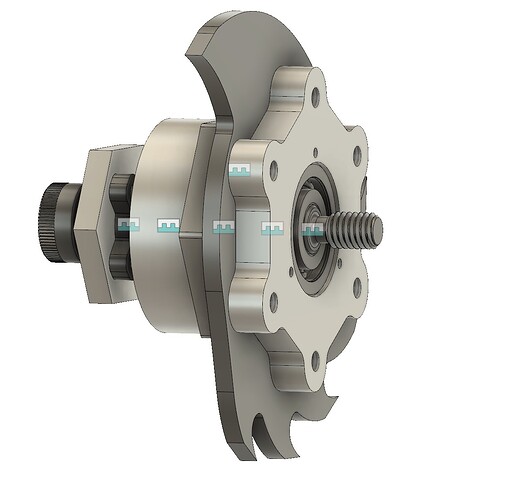

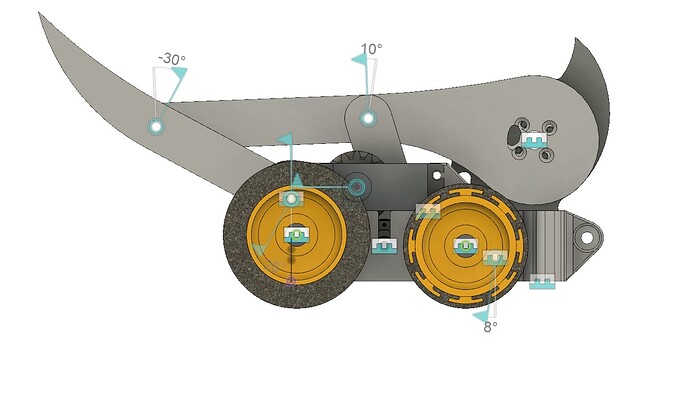

First, Repeat Robotics released their antweight hubmotor, which was lighter, cheaper, and way less effort than the custom hubmotors I designed for Attitude Adjuster. They also have a lower kv, which let me go to 4S and still be under 250mph with a 100mm blade. This also unlocked the second thing I was stuck on, which was finding a battery. Sion pointed me towards some 650mAh batteries that were exactly the size of the space I’d left that was previously too small for a battery.

Finally, I got around to flashing the old Aikon 35A 4-in-1 ESCs I had lying around with AM32. Mega shoutout to AlkaMotor for helping me through the process, I have no idea how they have time to help all the n00bs like me.

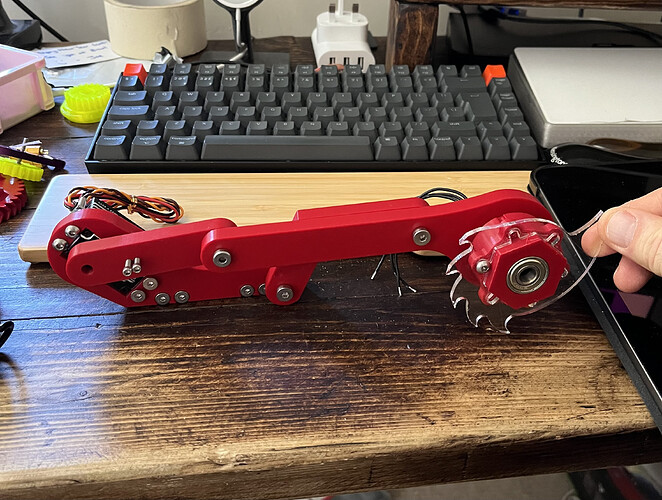

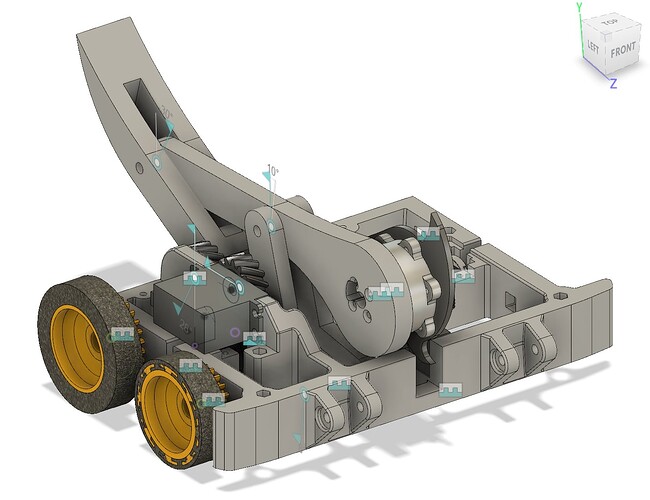

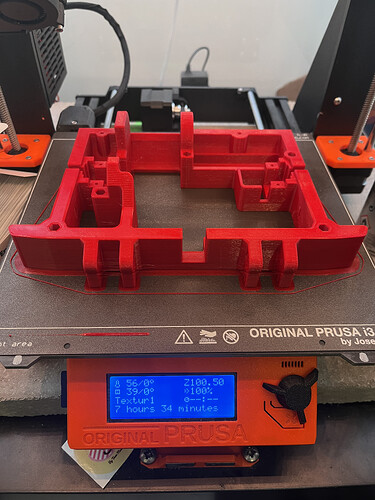

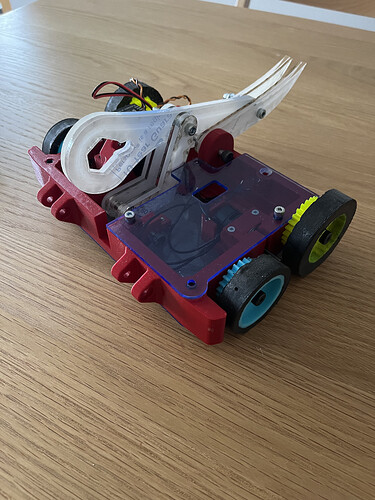

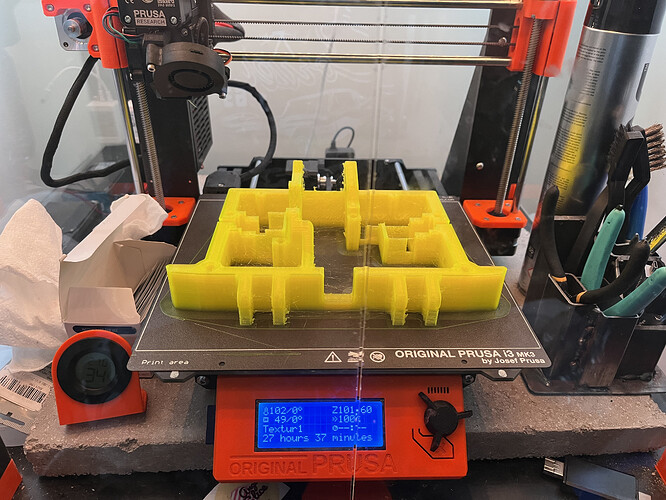

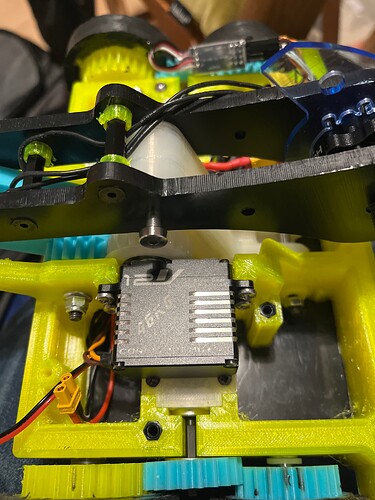

This let me print a final test fit prototype. The big constraint was the size of my print bed, I didn’t want to split the chassis in two like I did for Attitude Adjuster since the weapon uprights were integrated with the chassis. I used a combination of the 30mm aluminium hex inserts from eBay, and thread-forming plastic screws. The Repeat hubmotor allowed me to make the chassis a bit more symmetrical, as it didn’t need the arm to be as offset as my custom hubmotors. It also likes being double-supported, so that made the packaging a bit nicer, having arms on either side on top and arms in the middle below.

I decided to definitely enter Grey Area into Brawl as it was on my bucket list to compete with something that wasn’t Attitude Adjuster, and got cracking with the rest of the build.

As I locked in different parts of the design the robot went from prototype red to black, blue and yellow. I was going to use HDPE arms for the 4-bar, but decided to try a printed nylon piece for the front for strength and TPU for the back to give it some flex. I was particularly worried about the nylon piece, I thought it would either explode when I hit something or explode if/when it was hit. I printed a spare and also brought a backup PLA-ST to the event.

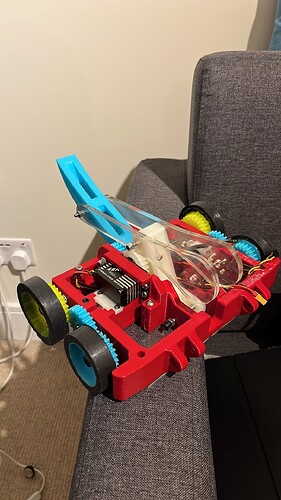

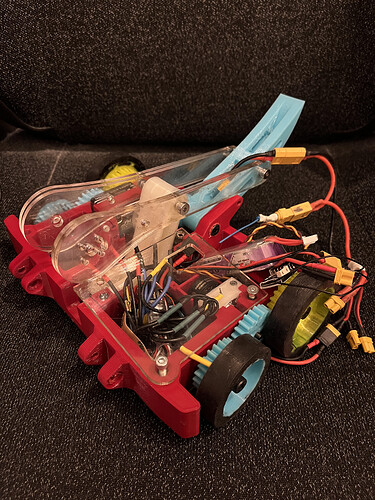

I printed the final chassis and put it together with the UHMW arms that I CNC’d. I got stuck on the wire management for the hub motor so decided to just go with what I had, so it wasn’t really well considered until the last minute and was super exposed at the top. I printed some sort of TPU channel, but they were still exposed on the top and this would come back to bite me later on.

I decided to go with a switch this time instead of a link, since BBB were going to allow them for Brawl. I did give myself an out, and designed the bot to use either a switch or a link if I didn’t like it.

By this point, I had enough for proof of movement! The self righting was a bit unreliable, which would also come back to bite me in the event.

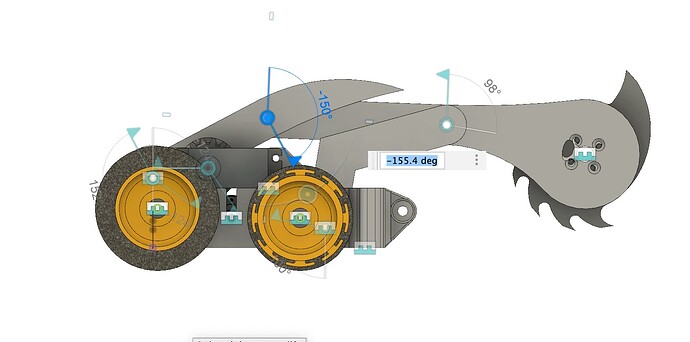

One interesting thing is I did some funky openTX programming for the servo. The throttle is used for the spinner, so that left the rudder for the weapon. This was my preference anyway, as it’s how I control the hammersaw on Attitude Adjuster. The servo is at full retract when the stick is centred, and moving the stick right extends it proportionally. However, I wanted it to punch, so I programmed in a “punch mode” so that when one of the switches is active and the stick goes past 20%, the servo goes to full extension. I left it in this mode for the whole of Brawl.

But enough worrying about important stuff, I took some time to print some cool locking bars.

The robot was mostly complete. I had to go for a TPU printed lid as the battery stuck out over the top of the black HDPE lid. I embraced it and totally ditched any symmetry, to Jack Tweedy’s horror. I also cut half of the “tail” off in the name of weight saving, which further compromised the self righting (foreshadowing).

The thing that really compromised the self righting was that the TPU chassis was so flexy that the servo was moving and causing the gears to skip when it was under any load, such self righting. This is workable in a motor-driven hammer saw but not a servo driven arm, where the position matters.

This was an absolute pain to solve, and was the single biggest problem with the robot. After much iteration and a full week or so, I solved it in a few ways:

- I left too much clearance between the servo gear and the arm gear. I had to experiment with funky gear mods to reduce the backlash. I think I ended up with something like mod 1.64.

- The TPU gear was flexy, which is good for absorbing shock, but was too flexy so it was causing slippage. I ended up separating the gear from the arm and making it out of nylon. I should’ve done this anyway, as I printed so many TPU arms that had to go in the bin.

- Adding a PLA-ST stiffening brace, which also doubled up as an armour mount to put a bit of TPU over the servo.

Grey Area was too heavy to reuse the trusty 2mm titanium wedge from Attitude Adjuster so I decided to design and print a new one out of TPU. I was wary of horizontals like Baby Dead Bod slicing through TPU, so I put a 2mm titanium panel on the front for deflection. I was also wary of saws or hammersaws going through the TPU and hitting the battery so I panic-cut a lid out of 2mm titanium too.

And then after getting some sweet stickers, getting some cool blue cable sleeving, and casting some blue wheels, we were ready to go!