So, Subterranean Showdown has come and gone. Firstly, what a venue. Super cool vibe and also about 7 minutes from stepping outside to stepping onto a train home (handy as I had about 6 minutes and forty seconds) Everyone brought their A game and had some really impressive ideas on show. I didn’t socialise overmuch which I always regret but a good time nonetheless. I’ll breakdown some of my performance once I have scraped up the dregs of my build report.

I made a distinct push this time to go in and polish up all the little bits I was unsure about or had a little niggling feeling they’d fail. I have an awful tendency to get complacent and gloss over fairly glaring flaws in my robot, even with available time to address them just out of pride (admitting the infallible narcissist made An Mistake) or fear that I’d make something worse so I leave it. Well this time, motivated by a Schwarzenegger documentary I knuckled down and started fixing all the little horrors and quirks I could in the days remaining.

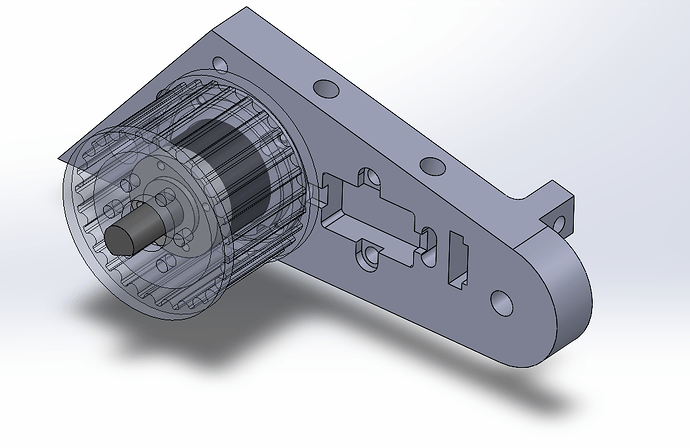

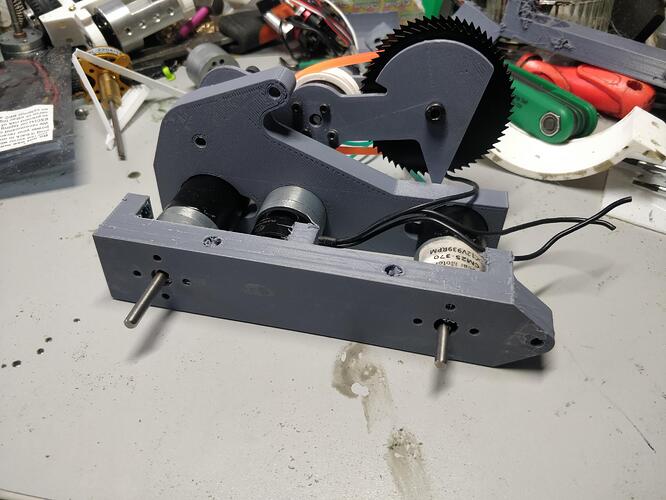

The arm was the biggest point of contention. Firstly I was worried about the motor for a couple reasons. Anyone who has dabbled in the fickle business of DIY brushless + gearbox knows that pinion slip can be an issue (as well as an embarrassing medical complaint) As this motor was going to have an even harder and more brutal life than normal with the blunt stops and direction changes I elected to go belt and braces and have a go at silver soldering the pinion on. It worked really pretty well and I got a nice clean joint - only inhaling a small cloud of vaporised acid as a by-product.

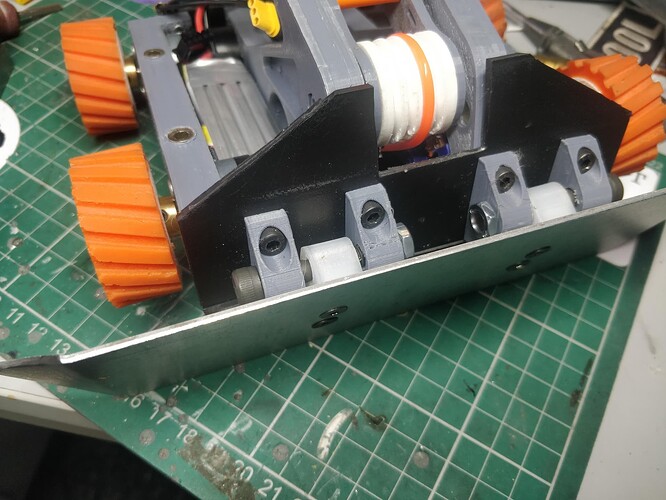

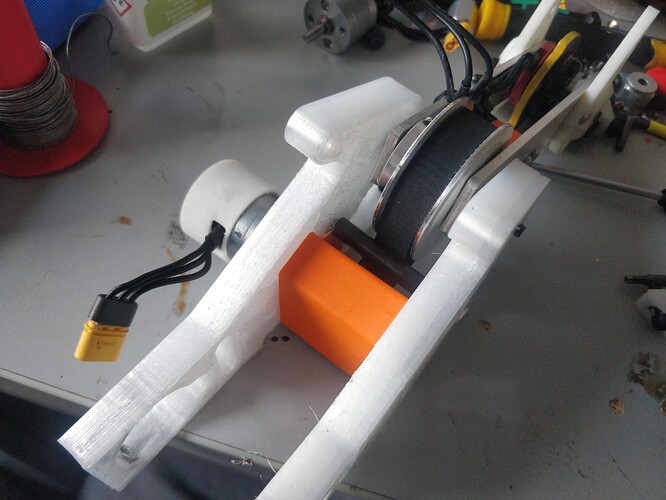

I was also a little worried about wire eating from the rotating back end of the 1806 and wishing to brace it back against the frame to keep it in place. I drew up a quick motor guard and slotted it over the motor while I had it apart to secure the pinion.

You can see how nice and snuggly it sits in the bulkheads. No silicone munching allowed!

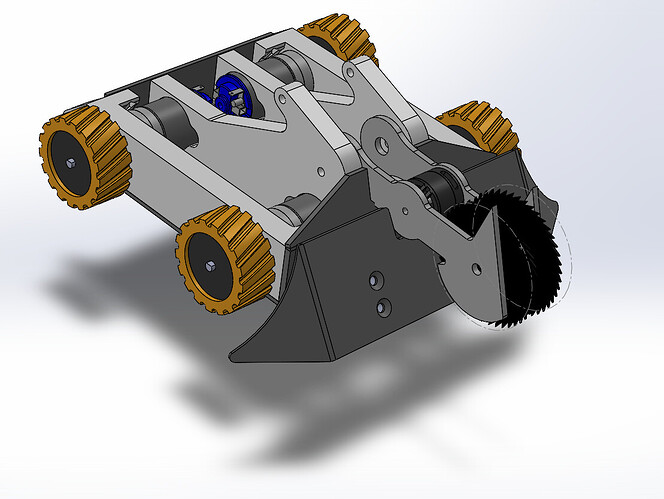

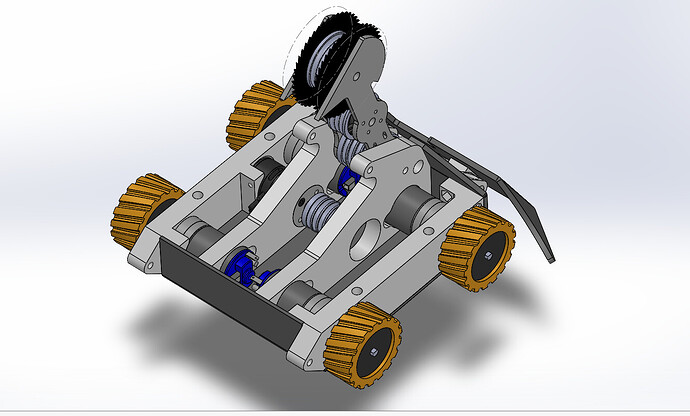

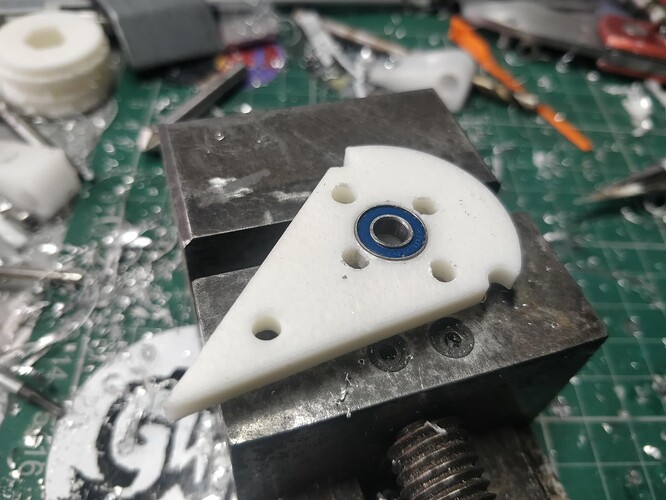

as while the O rings were great for style and acting like a clutch they slipped way too much to be consistent and reliable at self righting. After a brief consultation with the void at large I found I could scab in some GT2 timing pulleys in without modifying a thing. Technobots has these phenomenally cheaply so I just hit go and ran with it.

They needed a back breaker tensioner to get enough wrap and synch up the centre distance but other than that it was pretty much a drop in solution. I drilled and tapped the aluminium pulley for the aluminium arms I made previously and had a quick play. Very responsive and much more grunt.

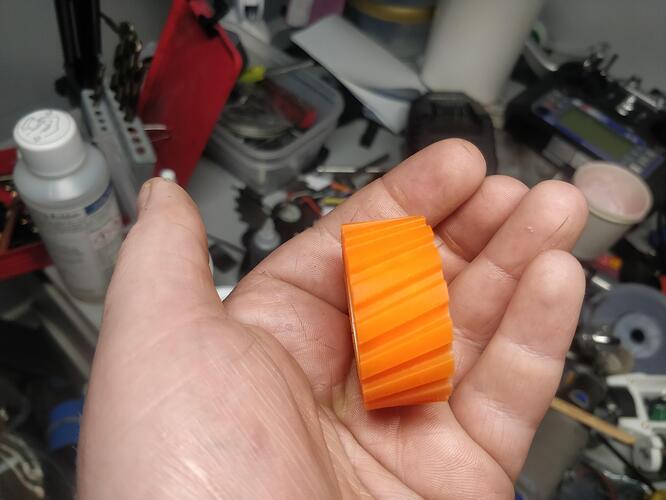

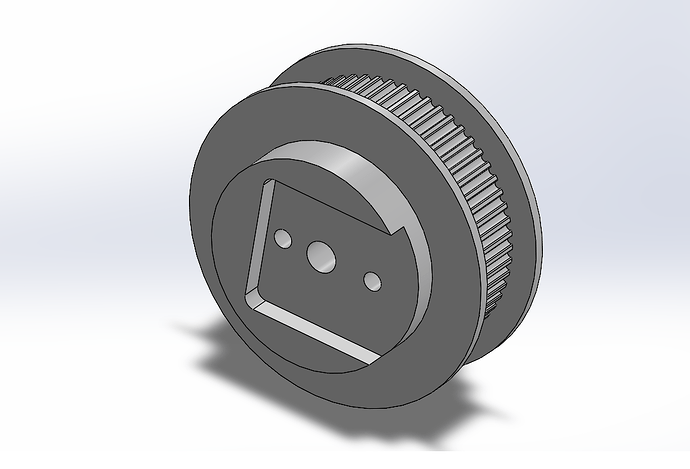

While the stock pulley was great, my lathe-less existence was hurting me that I couldn’t knock a bit off the boss then make up a spacer and have it central. Luckily I live in the future where you can just hit send on a part and get exactly what’s on your screen in mere hours. I drew a 59 tooth GT2 pulley (just to ease some of the ANGRY tension I had foolishly added) to replace the 60t aluminium one and printed it in ABS. It has the interlocking geometry for the arms. I just threaded direct to the ABS which works really pretty well (it shouldn’t, though)

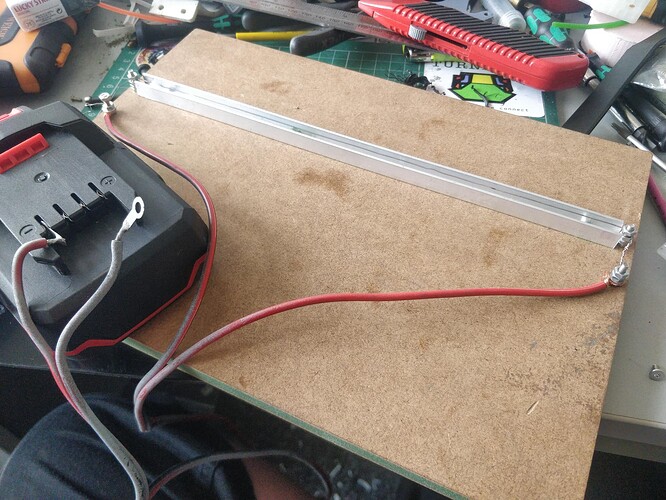

I also knuckled down and printed something to give an extra little bit of security in the form of a link flap. Again just ABS it piviots on one of the mounting bolts for the lid and latches on an M3. With a little bit of Klaus branding to, after all the link can’t fall out if its stuck in a K-hole

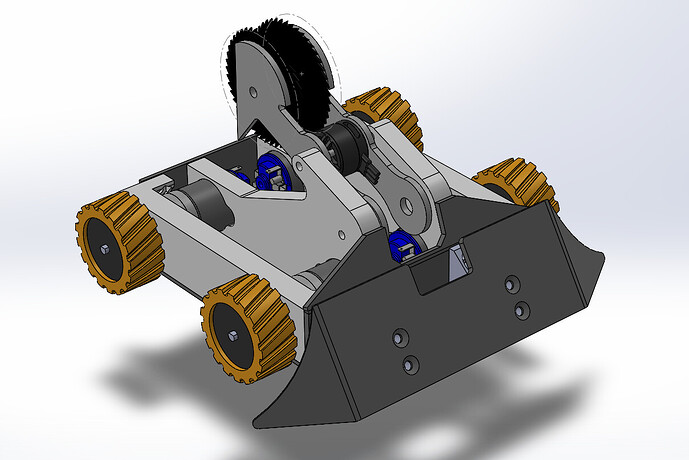

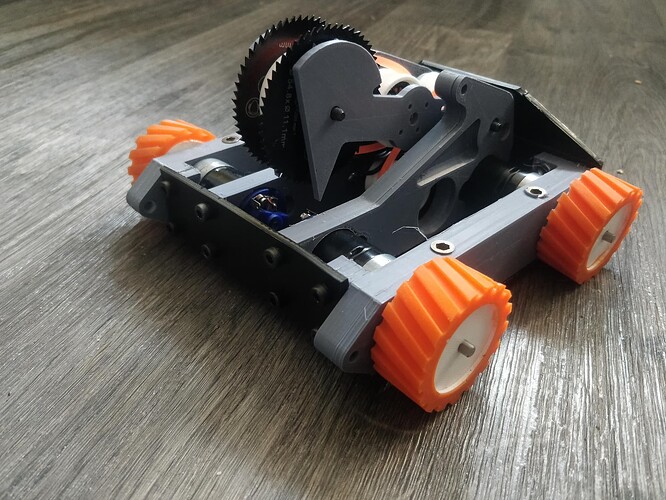

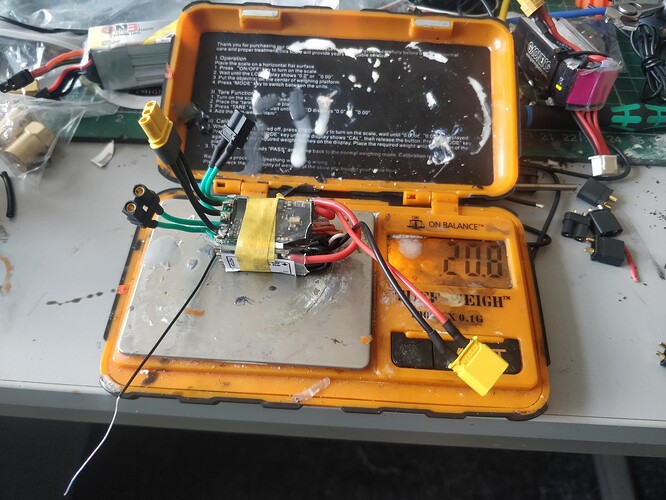

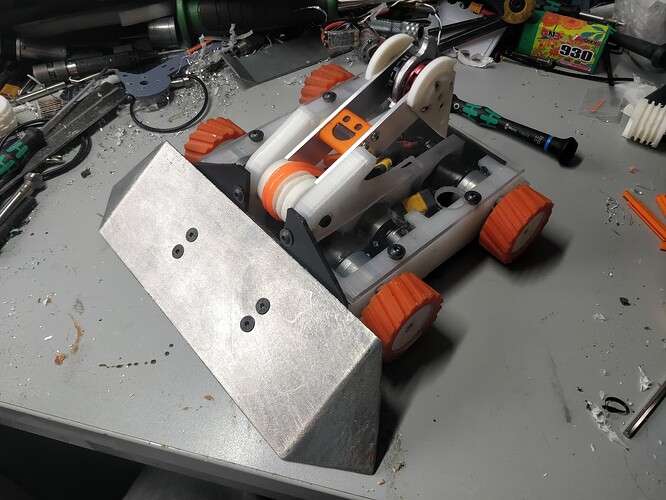

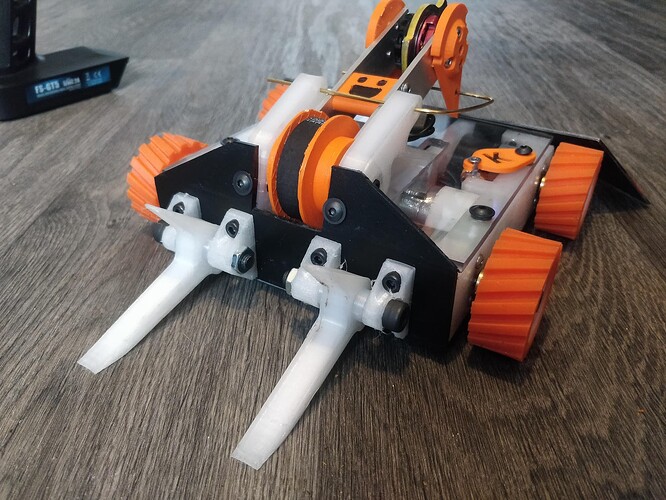

Getting to a finished state here and I was pretty happy with how it was setup. I had a good deal of options, wedge could be mounted front or back and I could have up to 4 forks on the front. I fitted two with magnets and the rest were just free floating. Weight was pretty tidy as I flew well under even fully laden with the kitchen sink setup.

Pretty mean stance - even if is a bit of a wet blanket in reality

Can’t beat a bit of branding either! I actually found I quite liked the wedge on the back. Might be something to design in to any later versions. The idea of being able to fend off attacks from the back while I poke around with my forks at the front is pretty appealing with the culture of 3 way melees.

So ends the build of Klaus which was a pretty laid back affair - even with the mad rejigging of the weapon arm at the 11th hour. I had some goals in mind for the bot, principal being “Don’t be MotherLoader” which it isn’t and therefore is infinitely successful. I wanted something that could drive hard and BOY did that succeed. The robot drove beautifully, was blisteringly quick and respectable in the power department. This was dulled slightly by the fact I drove it horribly. Just normal fat fingers and poor responses. Slow and steady would have been the best approach but that just was not on the cards. I had it doing figure 8’s and such on the kitchen floor quite handily but obviously this doesn’t compare to actual combat or proper target seeking. I took the dual rates down progressively in each of my 3 fights and by the last one my throttle was at 90% forward, 75% reverse and my steering was down from 80 to 60%. Must have worked as I went the distance - even if I lost.

The self righting was a let down in the end BUT I will take a slight victory here as even working the handful of times per fight before the grubscrews slipped and galled the shaft is a couple times more than it would have done without the extra effort which probably bought me a collective extra 20 seconds of invaluable fight time.

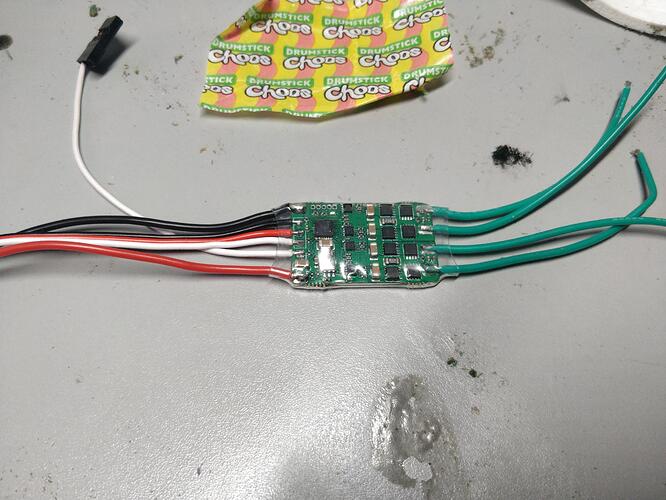

The direct drive motor was never going to make it past the event but I gave up after the second fight expecting it to do anything. It is not a write off as it stands but it is very, very unhappy. I will not be doing this again. I think it counts as a hate crime at this weightclass.

Overall a messy performance but not without valuable data. I liked working on Klaus and thinking about how to make it better. Simplifying will help (though it is already fairly brutalist in its approach) I can’t wait to not touch it for a couple weeks though - then I’ll start improving with fresh eyes and a brain on the cusp of it’s use by date.

LOVEYOUALLBYE