Ello. November draws near so this robot needs to exist pretty sharpish.

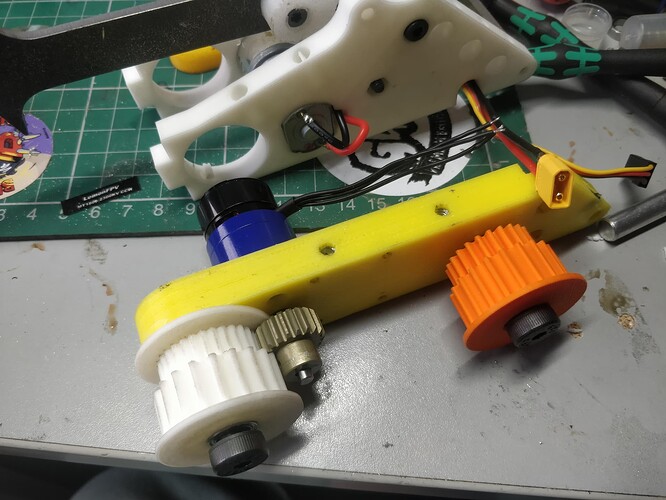

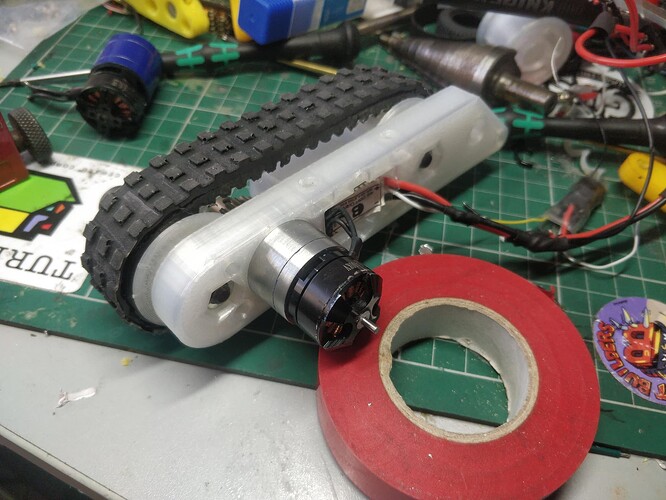

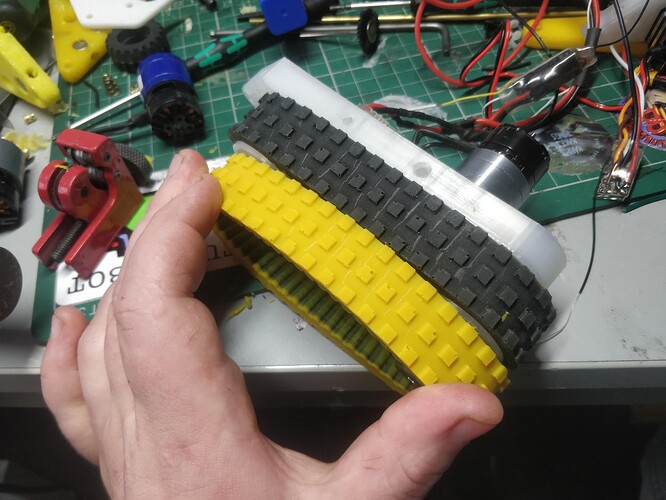

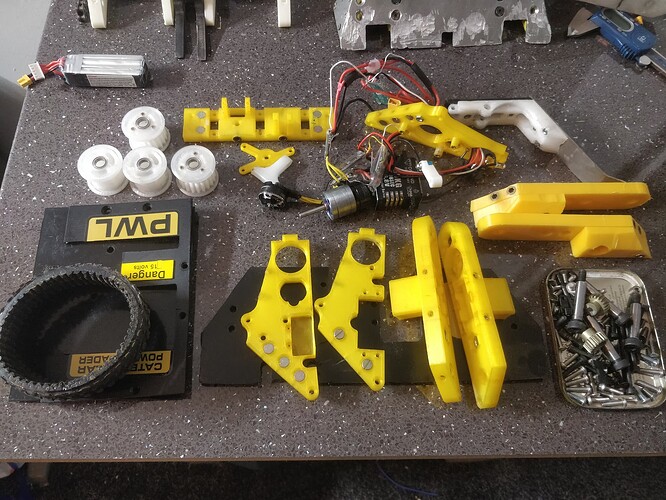

As we left off my parts were still decidedly white. This is acceptable for a slick, progressive young man like Klaus but wholly unacceptable for such a lumbering Neanderthal like MotherLoader. The yellow must endure.

No, I don’t need to drink more water*. I pulled the sneaky RIT liquid dye trick again and gave all the chassis parts a relaxing bath taking them from alabaster to buttercup.

The final colouring didn’t come out too far off the yellow HDPE so it’s not completely jarring. It is a lot less gold than the last version which I can put down to a better mix ratio of dye and a longer soak time. Also less awful and therefore more consistent prints.

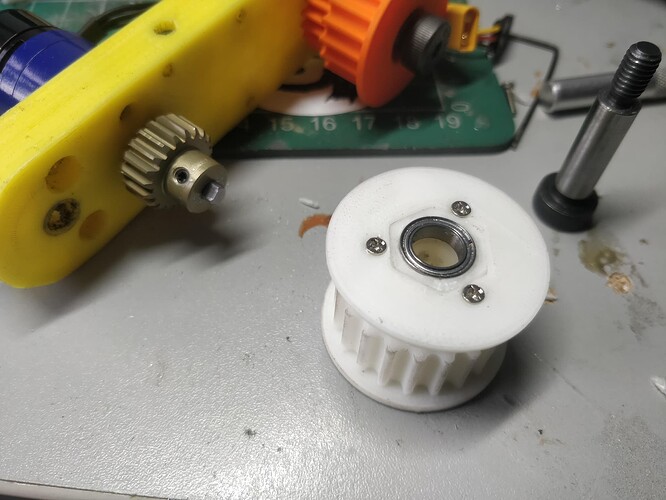

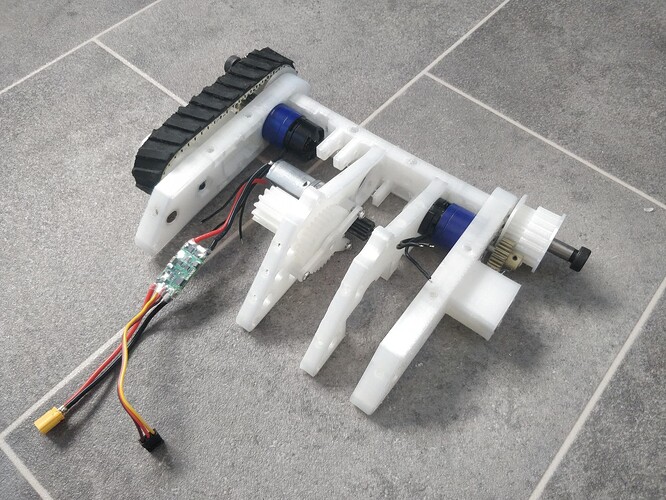

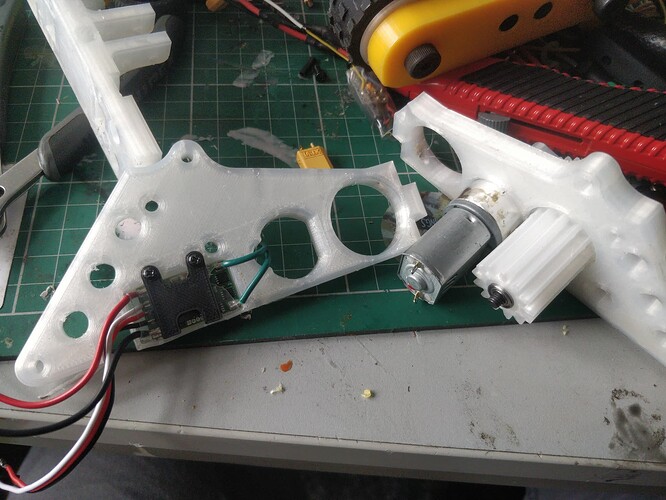

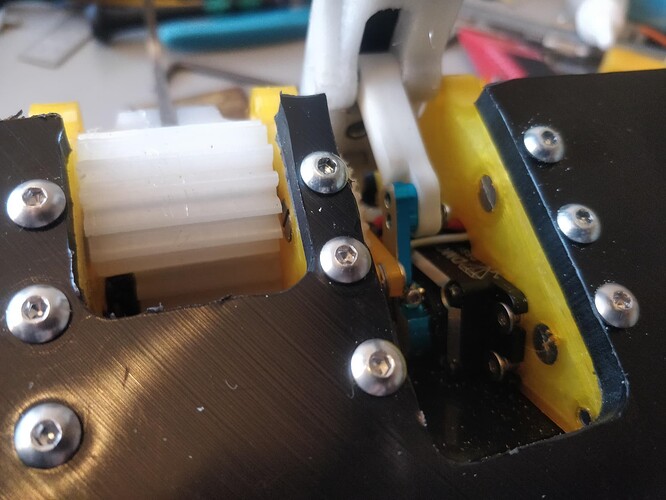

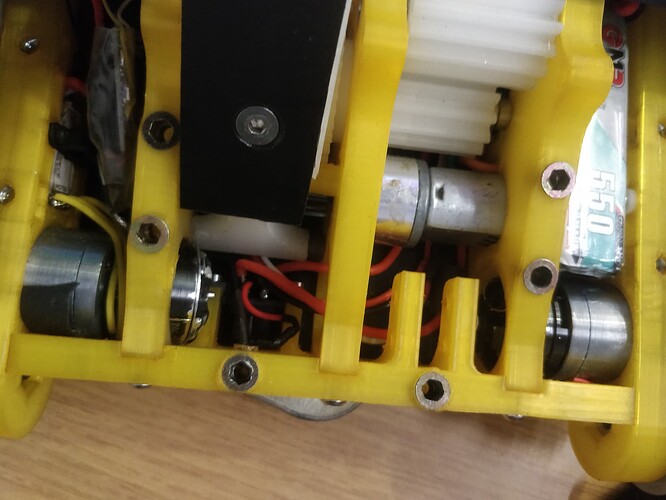

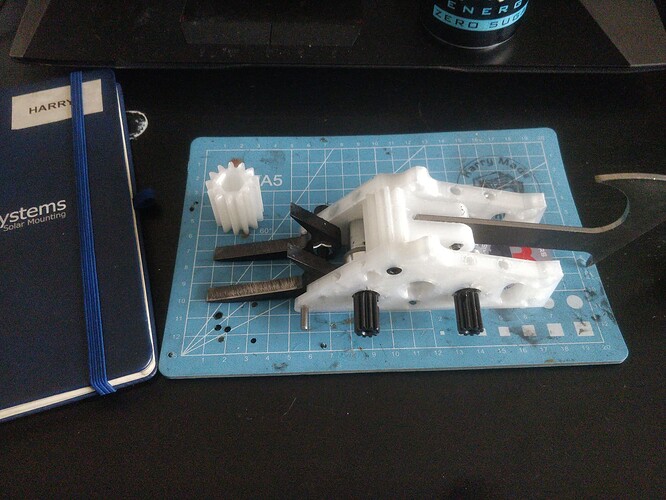

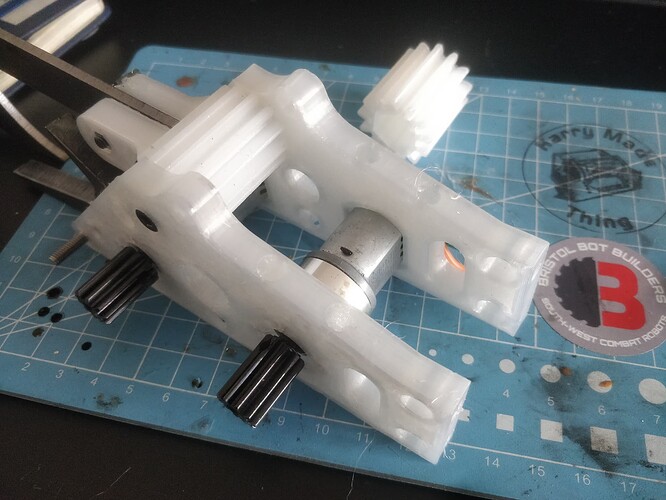

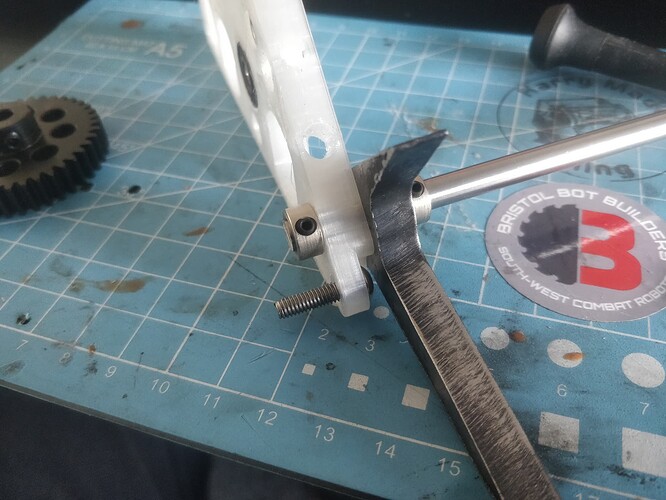

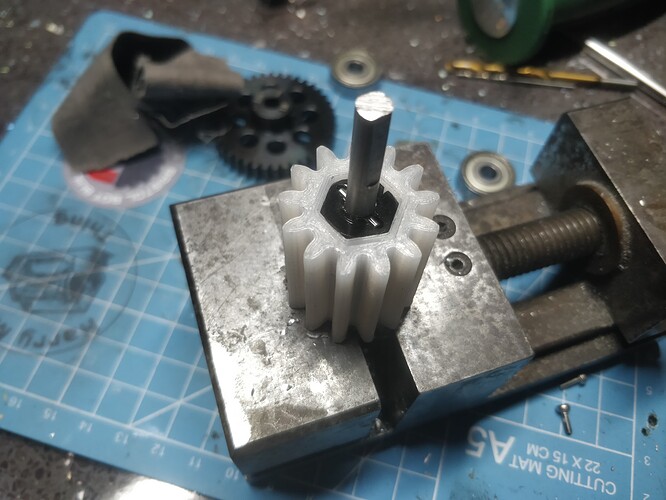

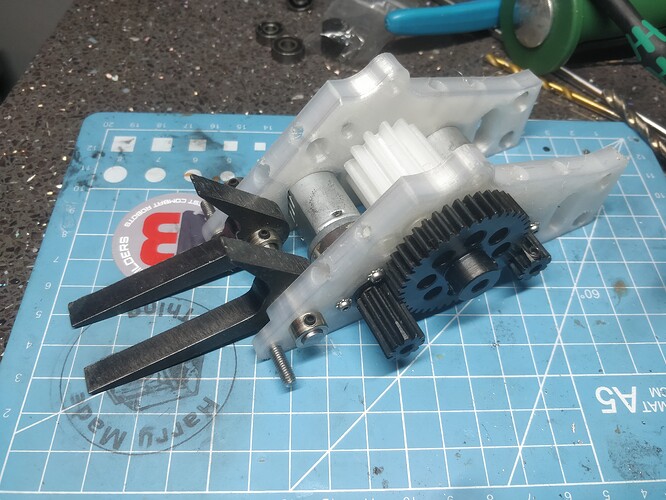

I separated church and state a little by letting any mechanical/transmission components retain their natural paleness and colouring the chassis and brace parts. Here you can see the first spur stage of the axe gearing. In an upgrade from the previous version the standoffs are now fitted with M3 heat press inserts instead of running long bolts all the way through and relying on captive nuts the other end. This means it’s a lot less of a chore to work on and brings the hardware count down. An amusingly long M4 performs the task of being a dead shaft for the gear. This is pretty sloppy but an acceptable practice for me as I have a pretty meaty pitch on the gear and there’s already some play from the % shrinkage I see from the nylon. It has to work for 3 minutes. It’ll be aight.

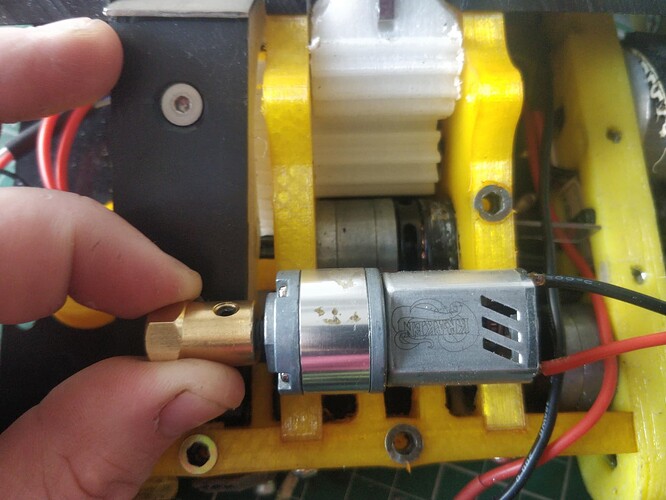

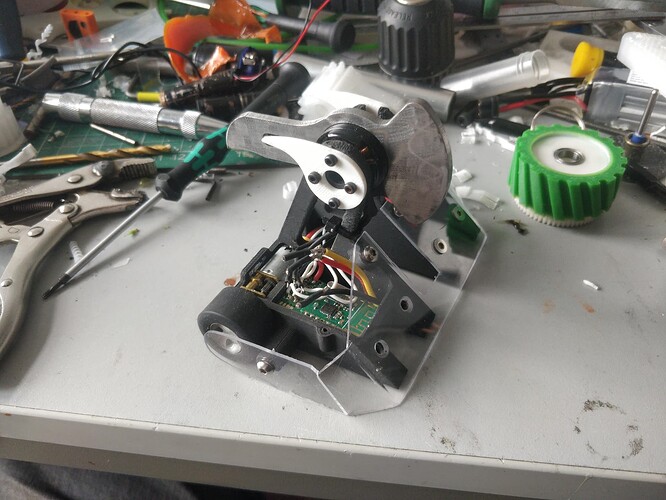

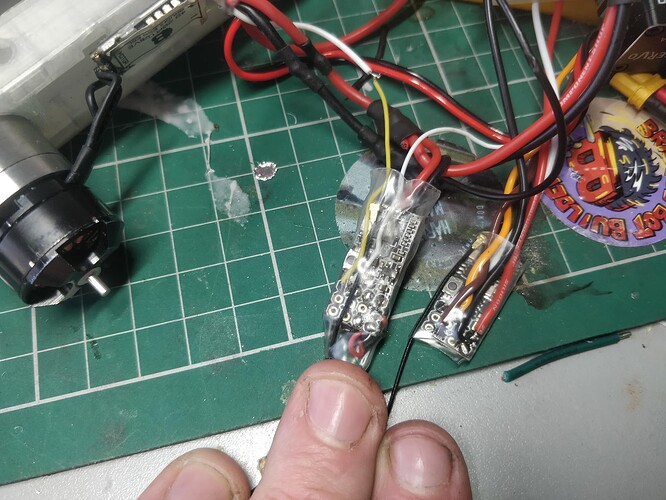

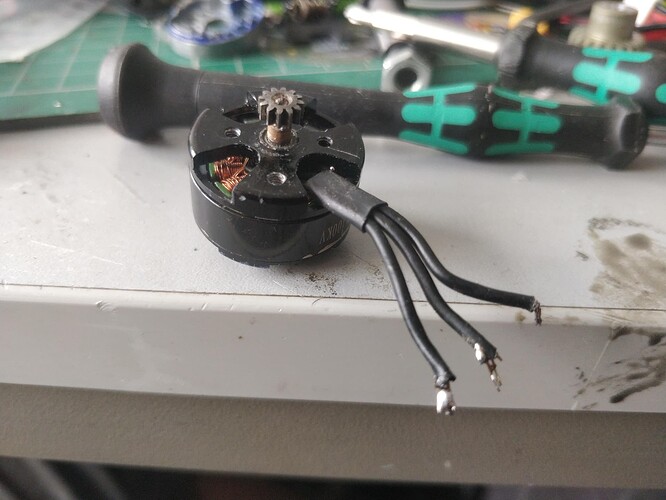

Not content with the mods I already had in place for my motors to increase robustness I also decided to dick around with the wires too. They were the horrible stiff wires used for the windings so they were also coated in this horrible insulating epoxy that’s a nightmare to solder to. I have to scrape or burn it off with brake cleaner or acid and inhaling the resulting DethCloud takes a good three years off my life. The amount of times I have had to do it I only have about six weeks left!

I went into the breach a final time and just stripped the wires back as far as I dared into the motor and fudged some lovely flexible silicone goodness up in there. I wrapped the joins in some adhesive heatshrink and then checked continuity. In hindsight I should have checked first but I am a Young Handsome Rebel with a Devil May Care attitude.

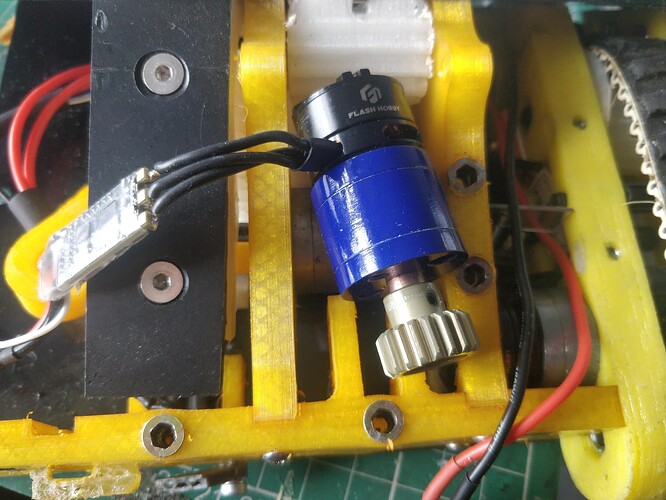

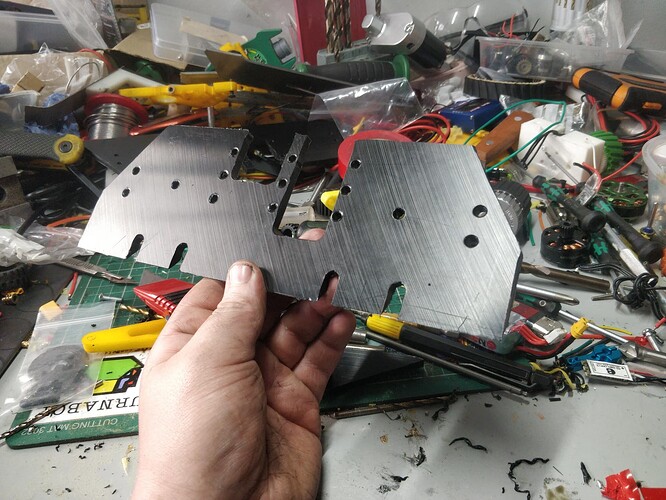

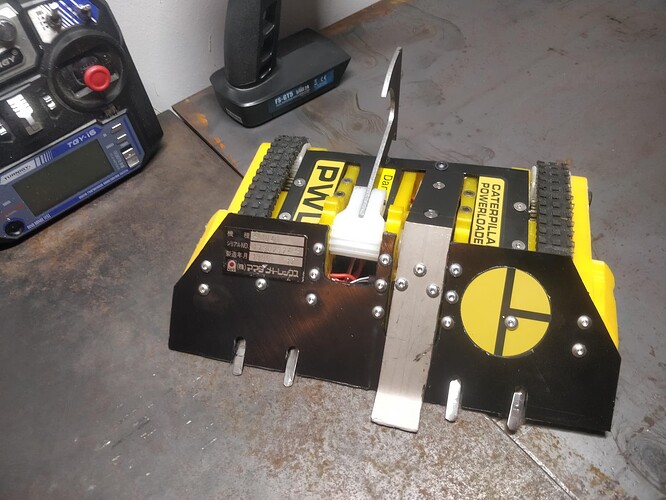

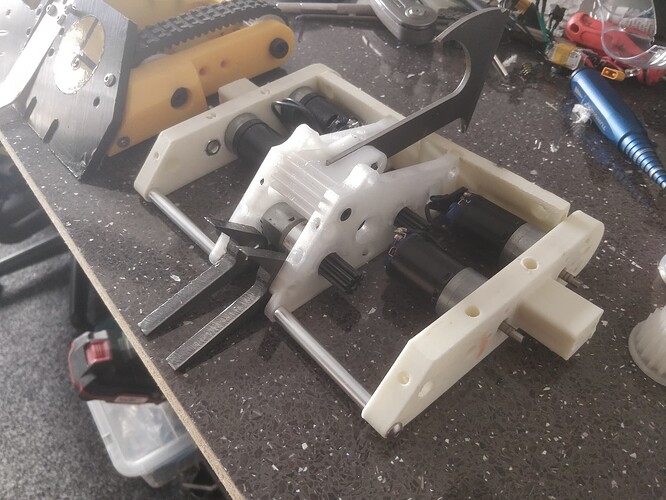

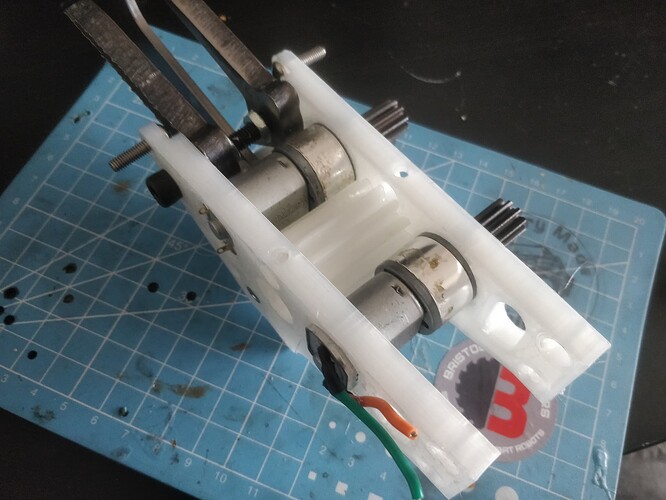

You love to see it - completed frame with all the little mechie bits slotting in and not interfering at all. Time to suck a lemon and try wiring the blasted thing.

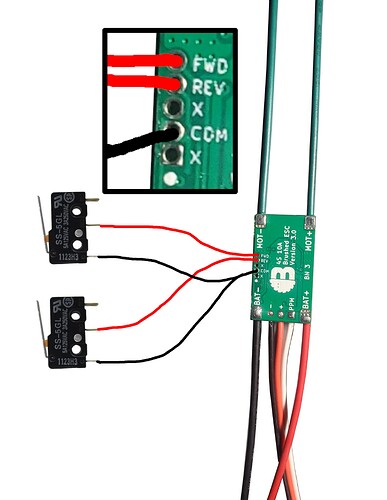

Wiring was a semi lucid blur as it was just as piggish as last time as I hadn’t been bothered to remove any of the hurdles or tight spaces. As the unfortunate nature of the robot demands, I couldn’t transplant the existing loom into the new chassis so it was a bit of triage to see what and where in the chain I could chop and patch. Long and the short of it - It now works so I am very much leaving it alone.

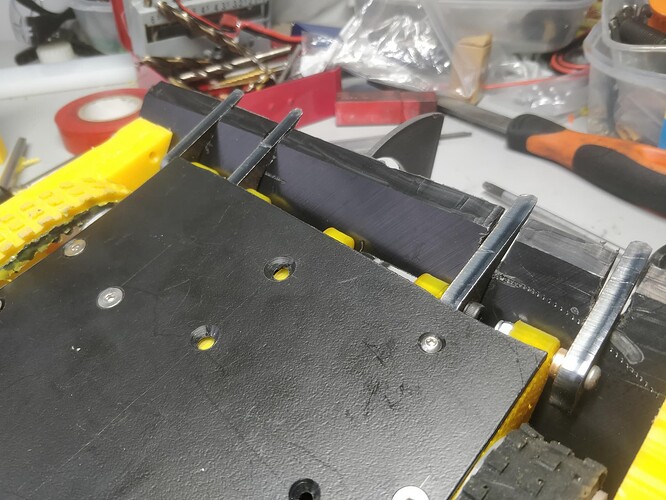

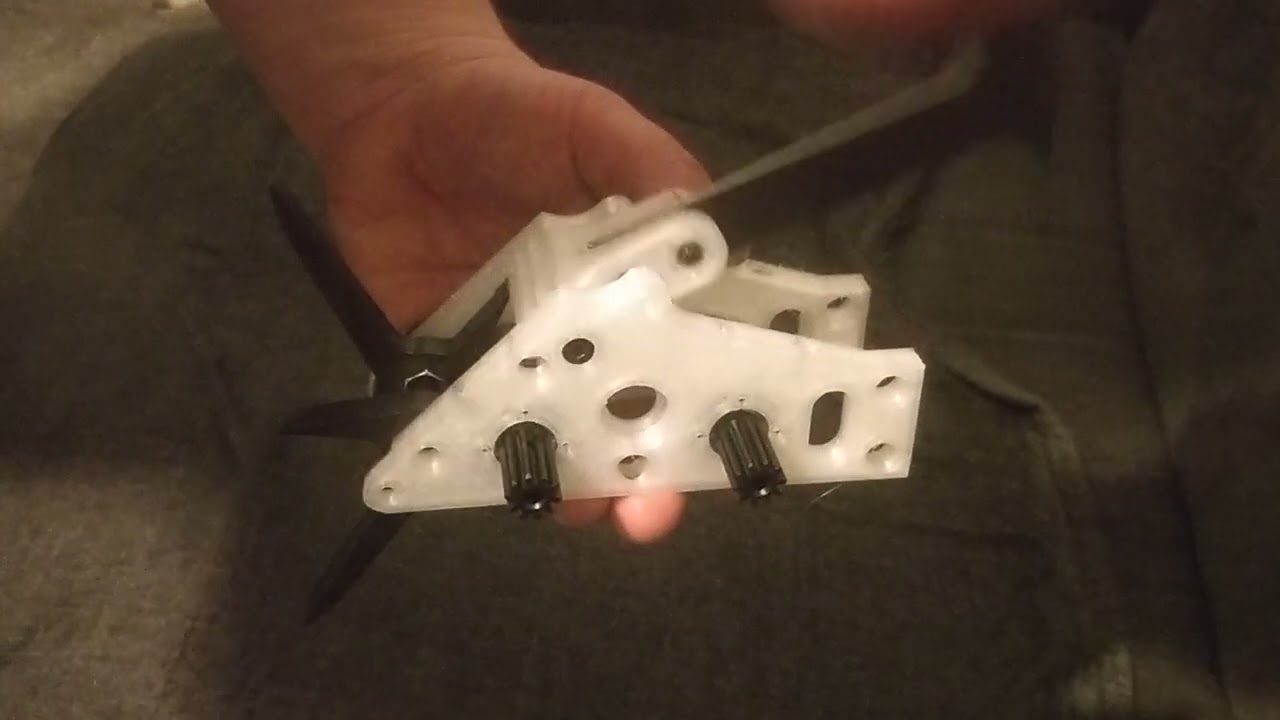

Also I have become boring and added little jabby forklets to ML to try to tryhard a little harder. They are short and stubby (comme moi) but will be better than nothing. They have a little teardrop bulge in order to prevent unintended rotation.

I did a very rough and ready print of a template for my wedge to make out of 6mm UHMW and routed it out. It came out rather well and I was pretty pleased. Big love to this method!

Who needs CNC? Well, me in order to make the template to then handcut the part BUT STILL.

The forks sit in the gaps quite neatly too.

So there we have the current state of ML! Mismatched tracks and horrific hotchpotch of bolts at present but it is pretty damn close now. He moves pretty well, not going to be setting any land speed records but the increased reduction has made it quite nice to position at low speeds and I don’t have it complaining about rapid direction changes as it suffered from before. I’m not 100% satisfied with it to be honest but it’s as good as I can make it without a bit of a rejig. We’ll see how it goes. Forward, hopefully.

This chunk of beetle progress has been aided in no small part by “Peachy Keen” monster energy and the soundtrack was this bop.

- I absolutely do need to drink more water but that is besides the point.

BYE