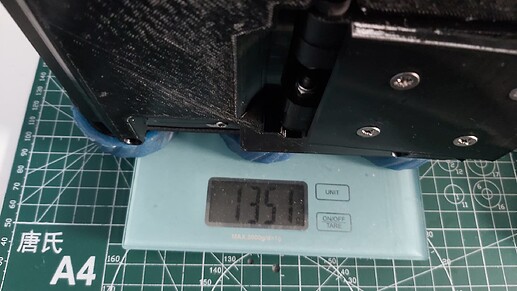

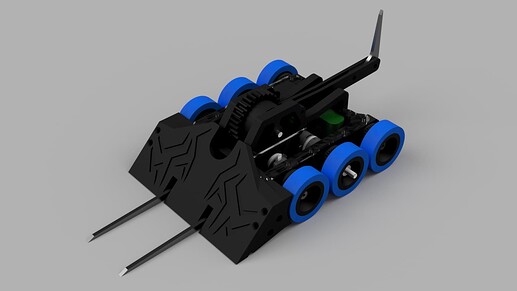

Data Breach took part in the Robot Rebellion this past weekend. Sadly our 4th run at Robot Rebellion was plagued with issues that robbed Data Breach of a good performance. Here’s the event report.

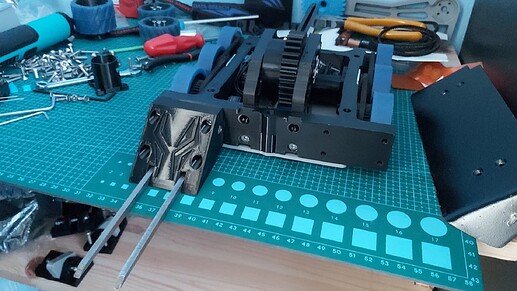

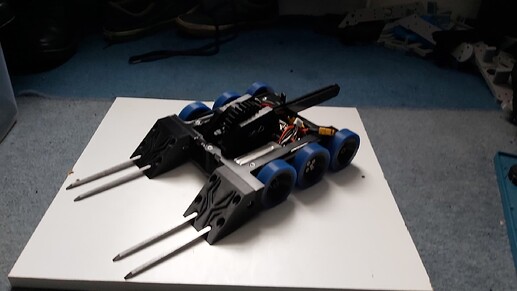

After passing Tech Check, DB was set up with the lifter to take on Attitude Adjuster. Scott wasn’t available this year, so Jack from Kitchen Grill drove in his place. It was going to be interesting to see if I could beat Attitude Adjuster with Jack’s limited time with the bot being a factor in my favour.

Sadly after a good back and forth DB suffered drive issues out of nowhere. One side stopped working then both stopped. Jack tried to help revive DB but the ablative TPU armour was too damaged to offer any more protection and I tapped out.

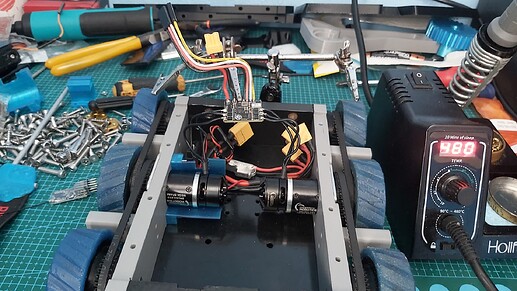

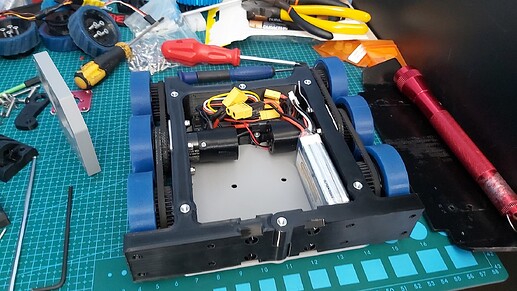

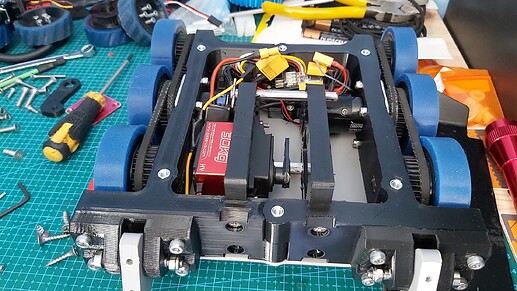

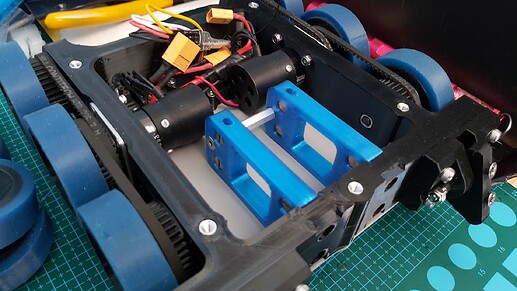

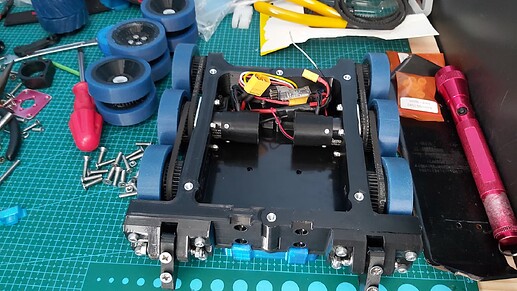

After returning to the pits to inspect the bot I was puzzled. No loose connections, no loose grub screws, the battery had plenty of power left and nothing had burnt out. I powered up the bot to do a bench test and the drive started working again. Whatever caused the cut-out was still a mystery. I had to simply hope that if it happened again a quick power cycle of the transmitter would fix it. Talking with Ellis, the strongest theory was that the Repeat Robotics AM32 ESCs might be cutting out due to some kind of electrical feedback from the drive during impacts. Sadly I didn’t have the capacitors that come with ESCs on hand to attempt to hopefully counter this by soldering them to the powerlines as Ellis suggested.

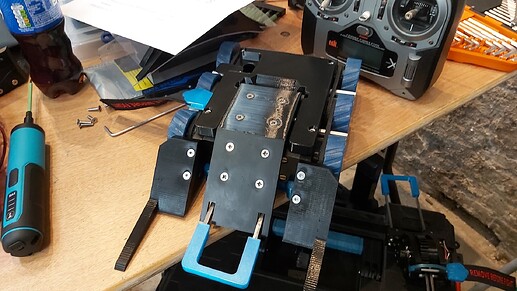

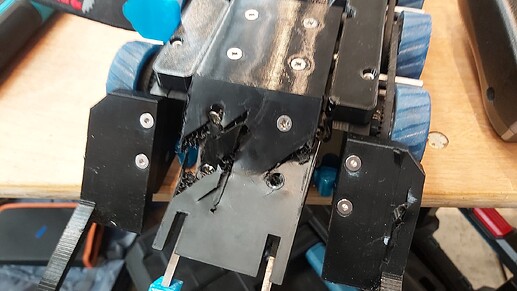

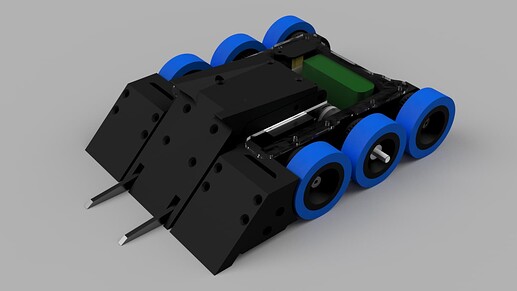

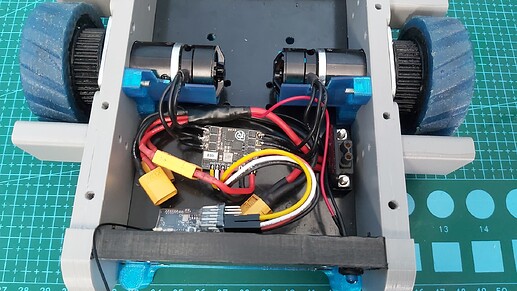

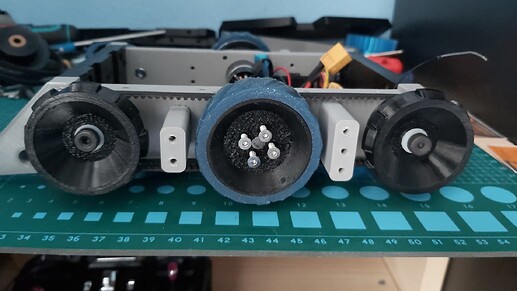

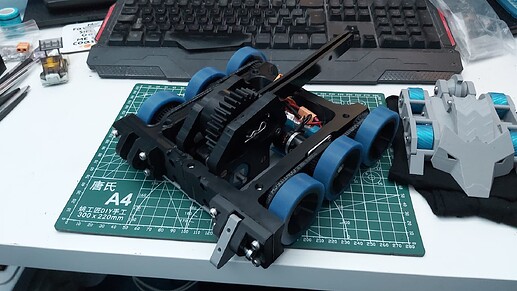

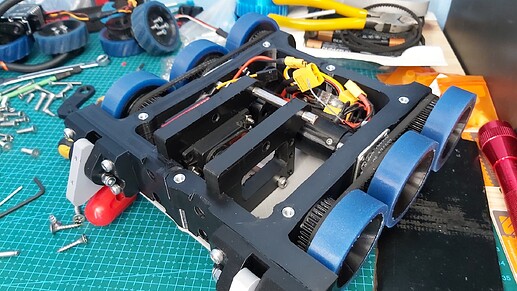

With that looming worry I reconfigured DB to run the standard Axe setup for Aggro Wobba which sadly brought its issues. The TPU chassis and side panels squish and flex a lot and annoyingly had started to squish into the wheels meaning the wheels were dealing with extra friction that hampered what should have been a good axe bot fight. DB lost by the judge’s decision. The inside of the sides had clear friction grooves from the wheels And my top had some nice marks from Aggro Wobba’s axe (no idea if I left any on Aggro Wobba’s top.)

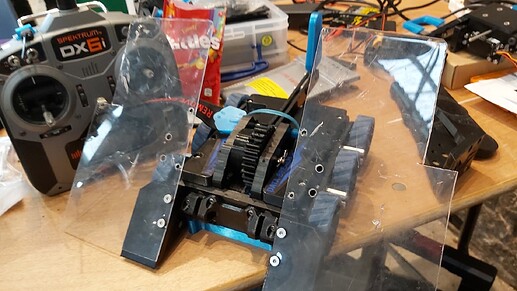

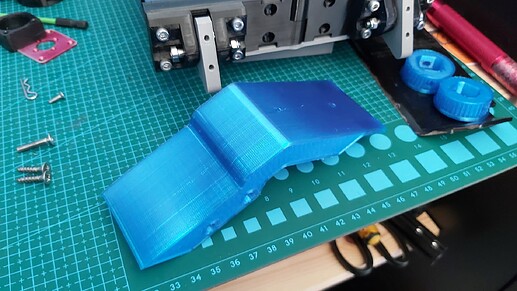

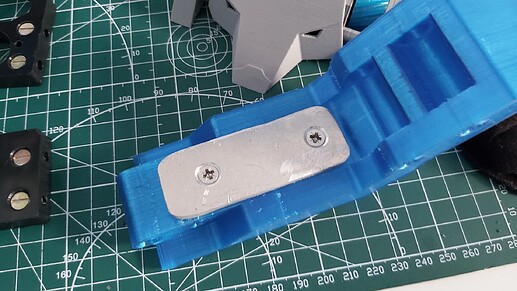

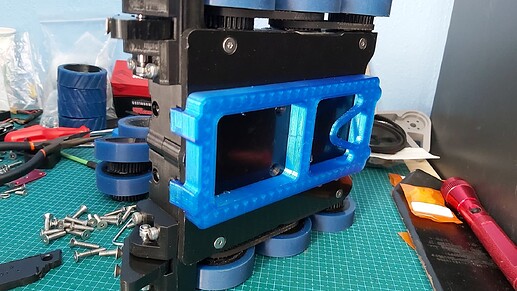

With two losses I was standing at 3 points on the board. I was now fighting for the 2nd place spot in the heat to have any hope of maybe progressing past the heats. I needed a win and Cormoran was in my way. I removed the sides and fitted the polycarb panels from my anti-big wheel setup which proved effective and I must say this was the most fun fight. With almost an oota and pitting to boot. Cormoran couldn’t reach DB with their saw but my axe had the reach which was handy for attacks.

As I attempted to ram Cormoran into oota zone we became entangled and we had the be freed. On the restart, I once again went on the attack and narrowly recovered from a drive cut out. But sadly both bots got entangled again when I attempted to pit Cormoran. This triggered a judge’s decision which DB won but at a heartbreaking price. DB needed a K.O. win to have enough points to earn 2nd place in the heat and a place in a 2nd place rumble for the remaining top 16 places. Missing out by 1 point.

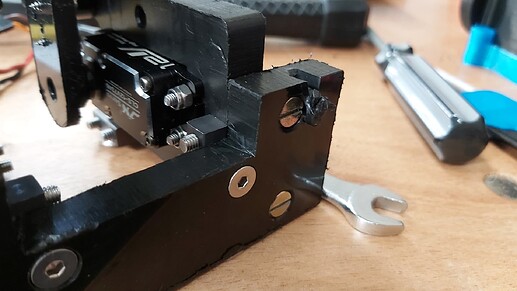

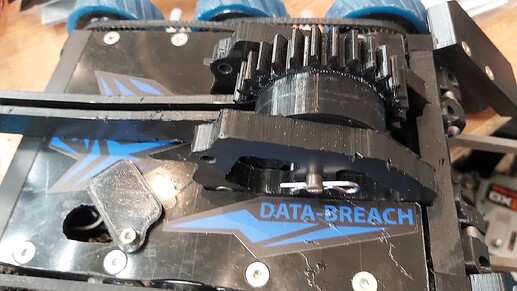

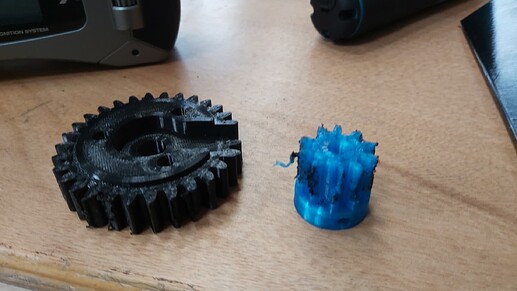

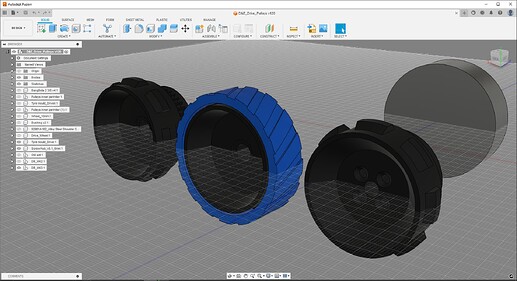

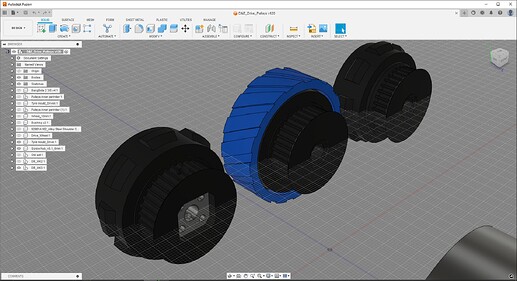

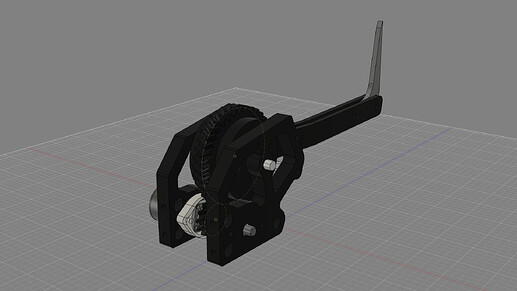

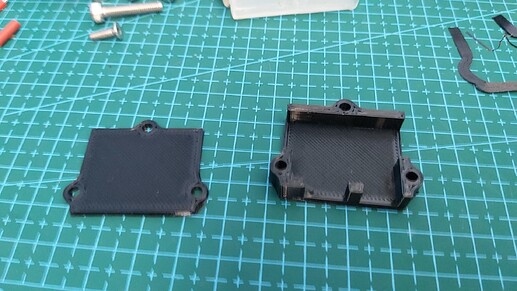

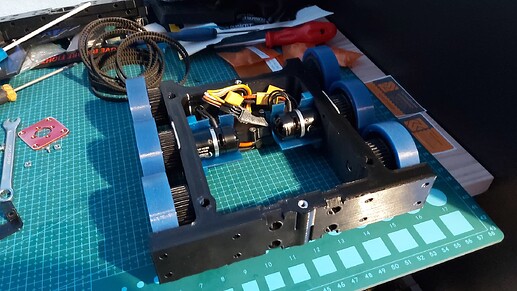

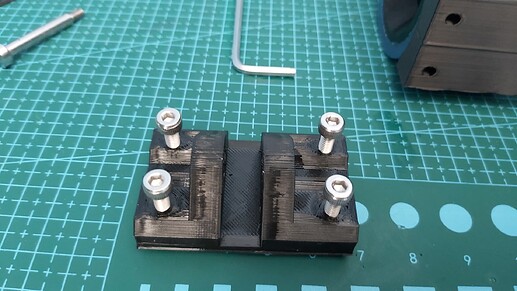

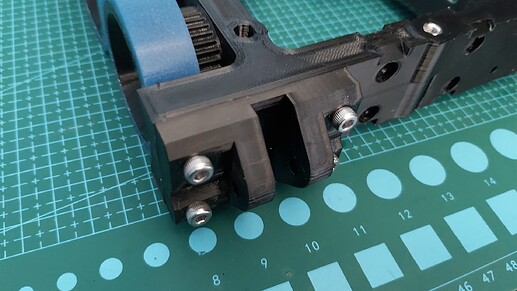

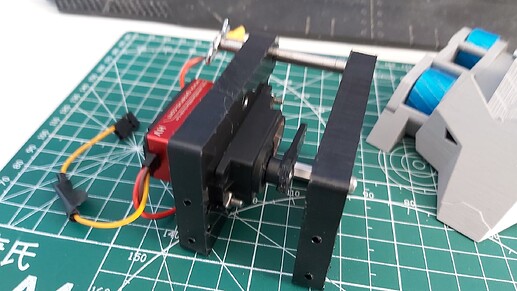

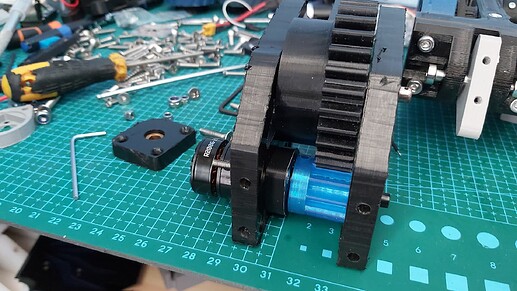

The polycarb was scratched a bit by the saw but more shockingly I had stripped the teeth on the weapon gears which I quickly replaced (improved serviceability for the win.)

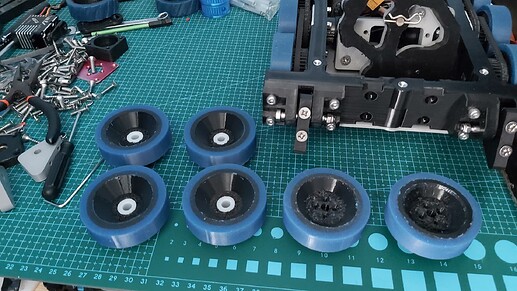

The next day I took part in the “This Is Fighting Robots” theme side event and sadly the axe decided to jam when it was turned over resulting in being counted out. Which was a shame as DB tanked some direct hits to the wheels and kept going. The TPU hubs were damaged and some chunks were taken out of the tyres but it kept going.

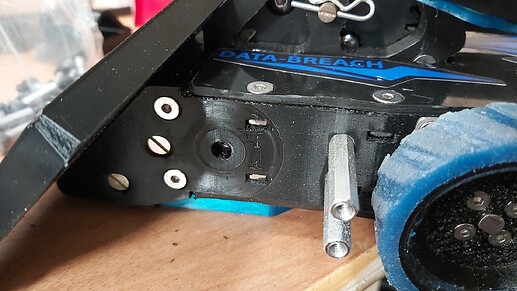

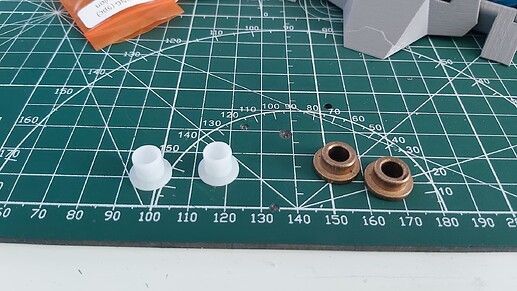

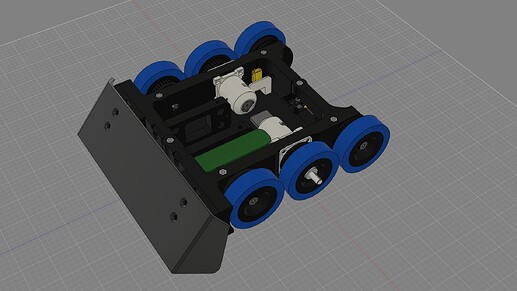

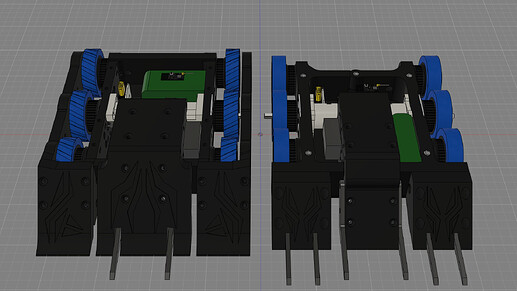

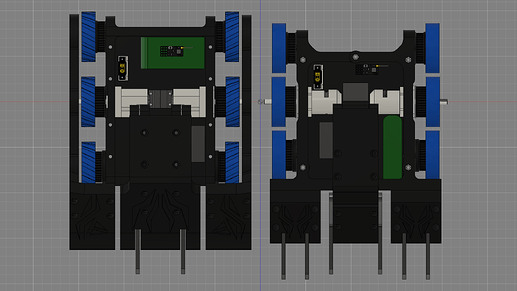

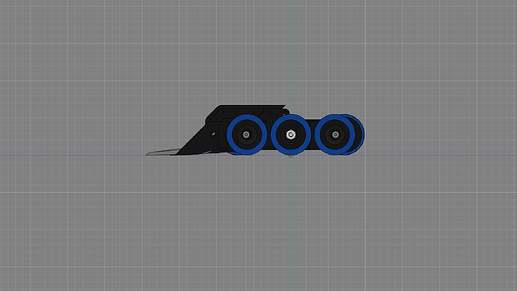

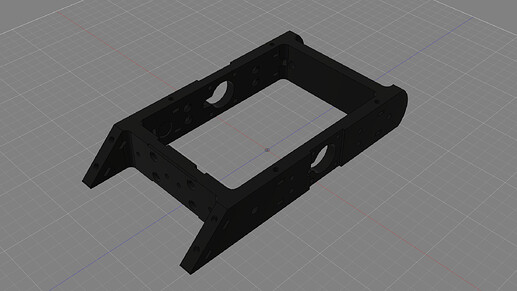

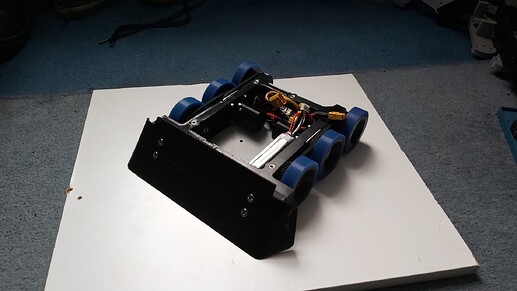

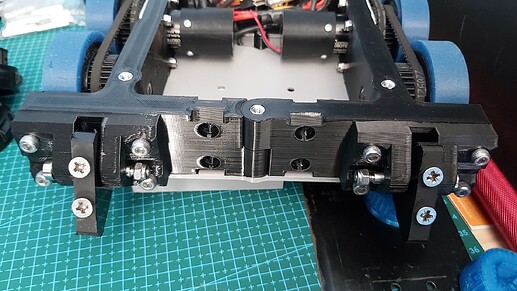

After removing the damaged wheels I had a look at the really bad rubbing on the chassis. During the discussion about my drive cutting out, Ellis suggested I angle the dead shafts outward by 1-2 degrees to counter the inward flexing the wheels were suffering to improve the drive and belt tension.

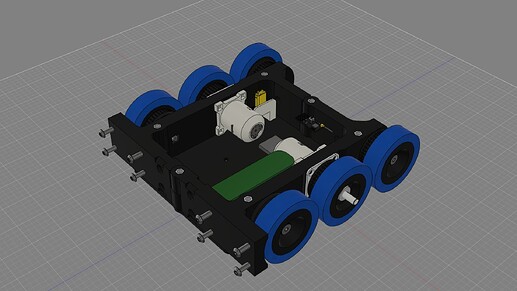

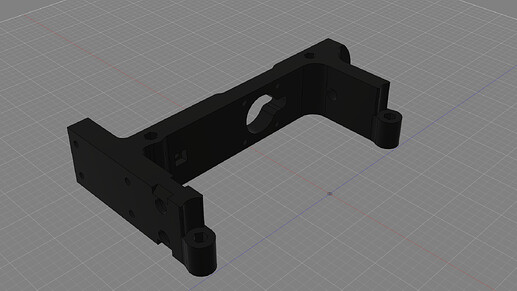

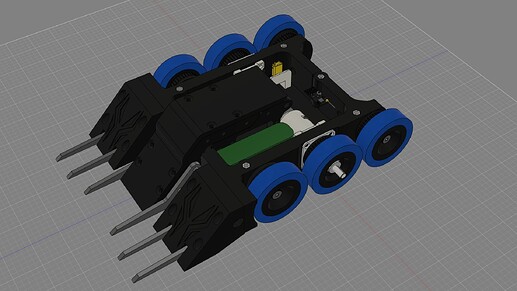

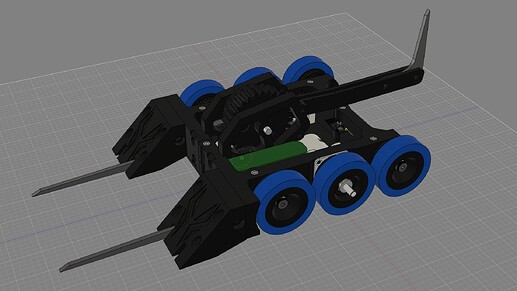

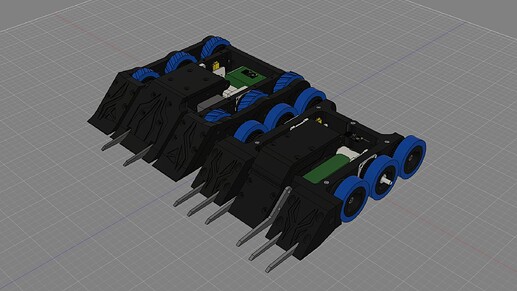

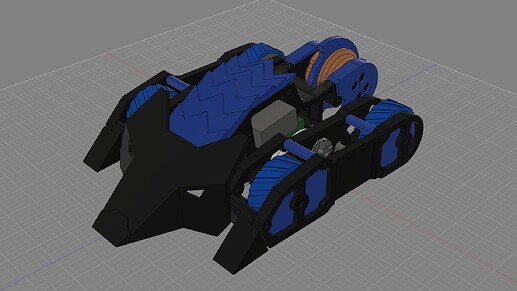

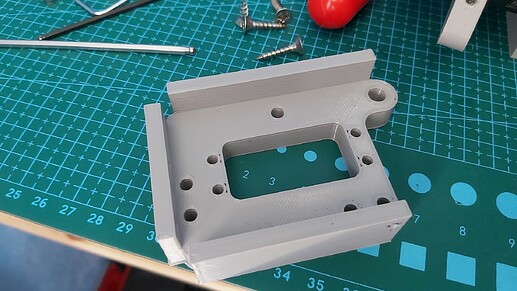

A shame DB failed to deliver. The weapons worked amazing even with the odd issue. The drive and chassis however are a letdown. I have thought through what needs to be done and have started to put it into the CAD for DB MK3.